the eight screws (PN 510106)

holding the power outlet assembly

plate with a 5/64" Allen wrench

and pull the assembly away from

the rear panel. Remove the front

cover (PN 850071) to the outlet

with a standard flat-head screw-

driver. Remove the two screws

(PN 510160) holding the outlet

with a 5/64" Allen wrench. Locate

the two wire retaining screws (Fig.

64) and loosen with a #2 Phillips

screwdriver until the two wires

(PN 870308) can be removed.

Remove the green ground screw

with a #2 Phillips screwdriver or a

5/16" wrench.

Reassemble the outlet in the

reverse order. Refer to the electri-

cal schematic for proper installation.

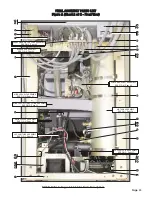

REAR COOLING FAN

The rear cooling fan (PN 540012) is located in the rear panel

assembly, below the waste compartment door (Fig. 65).

Remove the four screws (PN 510691) holding the rear panel

with a #2 Phillips

screwdriver. Tilt the

power input side of

the rear panel out-

ward to access the

wires going to the cir-

cuit breakers. At the circuit

breakers, disconnect only

the eight female connectors

from the eight wires coming

from within the unit (it is

not necessary to remove the

four wires coming from the

voltage selector). Swing the rear panel out farther to access

the white 2-position connector block (PN 860244) located on

the noise baffle assembly. At this connector, remove the two

wires from the fan. Remove the four locking nuts (PN

510411) and screws (PN 510506) from the fan with a 3/32"

Allen wrench and an 11/32" wrench. Remove the fan shield

(540009) and fan.

Reassemble the cooling fan in the reverse order with the air

flow indicator on the fan pointing toward the outside of the

unit.

WASTE COMPARTMENT LATCH

The waste compartment latch (PN 510678) is mounted onto

the waste compartment door, which is located on the upper

WASTE PUMP POWER SWITCH

The waste pump power switch (PN 830108) is the white rock-

er switch located next to the waste quick-disconnect fitting on

the power outlet assembly plate (Fig.

59). Remove the eight screws (PN

510160) ) holding the power outlet

assembly plate with a 5/64" Allen

wrench and pull the power outlet

assembly plate away from the rear

panel. Remove the four female wire

terminals from the rear of

the switch (Fig. 60).

Depress the retaining tabs

on the inboard sides of the

switch and push the switch

out through the front of

the plate. Place the new

switch into the rectangular opening in the plate from the

front side of the assembly plate. Ensure that the Off side of

the switch (marked with a dot outside the circle) is properly

oriented with the PUMP OFF nomenclature on the plate.

Reassemble the pump power switch in the reverse order and

refer to the electrical schematic for proper installation.

220 VOLT ACCESSORY OUTLETS

The 220 volt outlets (PN 840106) are the two European style

outlets located in the center of the power outlet assembly

plate (Fig. 61). Remove the eight

screws (PN 510106) holding the

power outlet assembly plate with a

5/64" Allen wrench and pull the

assembly away from the rear

panel. The outlets are comprised

of two parts (Fig. 62): To remove

the rear part, unscrew the center

screw from the front side with a

#1 Phillips screwdriver and pull

the back part out of the socket

from the rear. Remove the wiring

(PN 870309) to the rear part of

the outlet with a #2 Phillips

screwdriver. Use a 1/16" Allen

wrench to remove the front part of

the outlet.

Reassemble the outlets in the

reverse order, referring to the

electrical schematic for the proper

installation.

110V ACCESSORY OUTLET

The 110V accessory outlet (PN 840105) is located in the rear

of the unit, on the power outlet assembly (Fig. 63). Remove

Page 12

DISASSEMBLY - Continued

Figure 59

Retaining

Tab

Figure 60

Back

Part

Center Mtg.

Screw

Figure 61

Figure 62

Front

Part

Ground

Screw

Figure 63

Figure 64

Fan

Wires

Figure 66

Figure 65

Rear

Panel

Noise

Baffle

Assy