closed and attach the knob with the setscrew, allowing some

clearance between the knob and body. Ensure that the knob

does not bottom out against the valve.

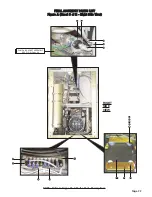

CHECK VALVE

The check valve (PN 730012) is located on the upper shelf, in

line between the bottle-select toggle and the 4-port manifold

(Fig. 95). Remove the

sleeve clamps (PN

730015) and tubes (PN

AA-94B) and remove

the valve.

Reinstall check valve

in the reverse order .

Ensure that the flow

direction is toward the

manifold.

35 PSI FIXED REGULATOR

This regulator (PN 730521) is located on the upper shelf, in

line between the manifold and bottle-pressure On/Off toggle

(Fig. 96). Remove the

sleeve clamps (PN

730015) and tubing

(PN AA-94C).

Replace regulator,

ensuring that the air

direction arrow is

pointing towards the

toggle valve.

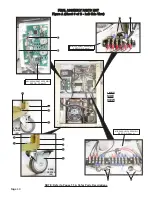

SCALER CONTROL MODULE

The scaler control module (PN 730500) is located on the

right side of the upper

shelf, behind the

divider wall (Fig. 97).

Remove the two

screws (PN 510530)

from under the chassis

with a #1 Phillips

screwdriver. Lift the module and

slide back the top cover on the

module to remove the electrical

connector to the module (Fig.

98).

Reassemble the control module

in the reverse order.

(PN AA-94B) and clear

(PN AA-94C) tubes to

the fittings, then remove

the tubes. Remove the

flow adjustment block

mounting screw (PN

510404) on the out-

board side of the divider

wall with a 3/32” Allen

wrench (Fig. 92). Pull

the adjustment block up

and remove the two blue and clear tubes to the block.

Replace label (PN 420748-07) if necessary.

Reassemble the syringe flow adjustment block in the reverse

order.

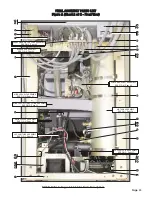

SYSTEM CONTROL VALVES

The system control valves are on the upper shelf, on the right

side of the unit (Fig. 93). They consist of two types of valves:

needle-type

adjustment

valves and toggle-type on/off

valves (Fig. 94). Remove the

tubing to all valves being

replaced. Remove all elbow

fittings (PN 730011), straight

fittings (PN 730062), and

nylon gaskets (PN 730074)

from valve bodies if neces-

sary. To replace a needle

valve, first loosen the

setscrew on the adjustment

knob (PN 850012) with a

1/16" Allen wrench, then

remove knob. For all

valves and toggles, use a

9/16" open-end wrench

to remove outboard nut

from the chassis wall.

Pull needle and toggle

valve bodies through

the holes in the chassis wall, from the inboard side.

To reassemble a needle or toggle valve, first remove the

mounting nut from the outboard end of the valve and turn

the inboard nut toward the body of the valve slightly. Then,

place the valve through the chassis hole from the inboard side

with the lock washer placed against the inboard side of the

chassis wall. Install the mounting nut onto the outboard end

of the valve and run the nut up just a couple threads from the

outboard end. Tighten the valve in place by holding the body

and tightening the inboard nut against the chassis wall with a

thin 9/16" open-end wrench. On toggle valves, ensure that the

toggle is in its proper orientation with the nomenclature on

the side panel. On needle valves, adjust the needle to fully

Page 17

Check Valve

Figure 93

Figure 95

Figure 91

Adjustment

Block

Figure 92

Figure 94

Needle Valve

Toggle Valve

Setscrew

FLOW

Manifold

Regulator

Figure 96

Flow Direction

Arrow

Bottle Pressure

On/Off Toggle

Figure 97

Scaler Control

Module

Figure 98

Electrical

Connector

Block Mounting

Screw