Page 6

the pressure switch cover with a Phillips screwdriver and

remove cover. Remove the wires from the switch with a #2

Phillips screwdriver and place on the new switch per the elec-

trical schematic. Leaving the cover off, install the new switch

onto the tank and reconnect the wire per the electrical

schematic. Open the top lid on the unit, raise the knob on the

pressure regulator (PN 730598), and then rotate the knob

clockwise to full open. This will allow the user to observe the

system pressure gauge on the top shelf while setting the pres-

sure. Power up the unit. CAUTION: The terminal blocks and

connecting wires are live when the unit is powered up. Refer

to the label inside the pressure switch cover to adjust the cut-

out and cut-in pressure screws. Adjust the cut-out pressure to

110 PSI and cut-in to approximately 80/90 PSI. Readjust the

pressure regulator back to approximately 80 PSI. Reattach

the pressure switch cover. There is also a tank-pressure port

available just below the pressure switch where a gauge can be

installed and used to observe the system pressure: Remove

the port plug (PN 730098) with a ¼" Allen wrench and install

a ¼ NPT pressure gauge of appropriate range. Turn the unit

off and remove the power cord.

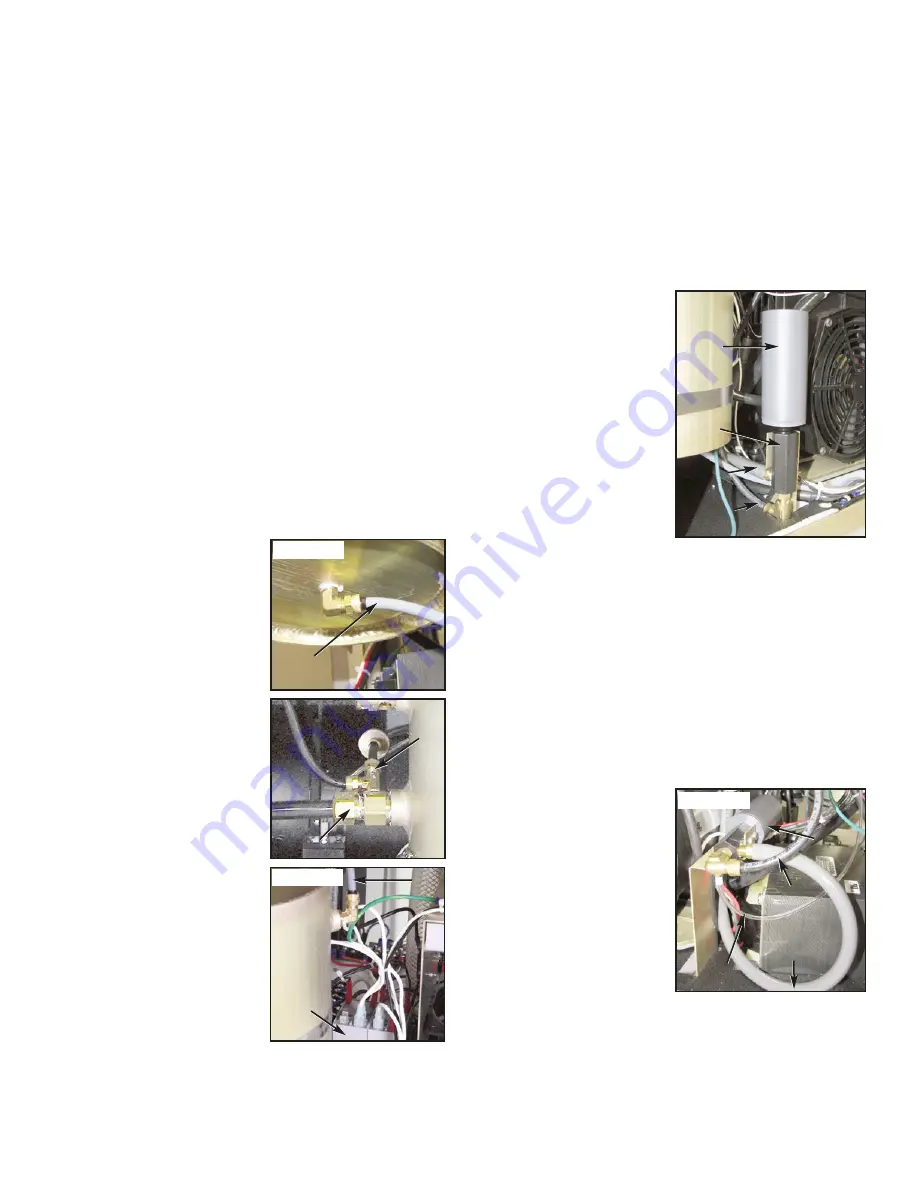

AIR TANK

Remove the drain line (PN AA-

95G) from the bottom of the

tank (Fig. 23) with a 7/16" open-

end wrench. Remove the two

lines going to the tee on the

check valve (Fig. 24) with a 7/16"

open-end wrench. Remove the

large tube from the check valve

with a 13/16" open-end wrench.

Remove the tube next to the

pressure switch with a 7/16"

open-end wrench (Fig. 25).

Follow the wires from the pres-

sure switch to the waste and vac-

uum relays and remove. Follow

the black wire from the pressure

switch to the terminal block and

remove with a #2 Phillips screw-

driver. Follow the long white

wire to the neutral terminal

block and remove with a #2

Phillips screwdriver. Loosen the

caster under the tank with two

¾" wrenches until the nut is held

onto the caster with minimal

threading. Open the top lid on

the unit and lock in the raised

position. Swing the instrument arms to the left side of the

unit. Remove the two screws (PN 510404) attaching the right-

hand vertical angle (PN 461665) with a 3/32" Allen wrench.

Undo the three clamps (PN 510514) around the tank with a

5/16" socket or a standard screwdriver. Use a 5/32" Allen

wrench to remove the two screws (PN 510477) on both sides

of the angle that attach the upright bracket (PN 461665) to

the chassis. Lift slightly on the top shelf to tilt the upright

away from the unit. Remove the tank. Remove all of the com-

ponents from the old tank and replace onto the new tank. For

tools required, see instructions for the tank components.

Reassemble the air tank in the reverse order

RIGHT VENTURI ASSEMBLY

Remove the two mounting

screws (PN 510404) from

under the chassis with a 3/32"

Allen wrench. Remove the vac-

uum tube (PN 730373) from

the vacuum valve assembly

(Fig. 26). Remove the pressure

line (PN 730130) to the venturi

(PN 461851) with a 7/16" open-

end wrench. To remove the

venturi from the bracket (PN

461897), remove the two

screws (PN 510309) from the

bracket with a 3/32-inch Allen wrench. If the venturi is

plugged, it is possible to repair it by removing the elbow fit-

ting (PN 730351) from the venturi nozzle (PN 461852) with a

7/16" open-end wrench on the nozzle and a 9/16" open-end

wrench on the elbow fitting. Then remove the nozzle from the

venturi body with a 7/16" wrench for the nozzle and a ¾"

wrench for the body. Then clean out the orifice in the nozzle

using a drill with a 0.048" diameter bit. Ensure that the orifice

is clear with no chips or burs, which will affect performance.

Reassemble the right venturi assembly in the reverse order.

LEFT VENTURI ASSEMBLY

Remove the vacuum tube (PN

730373) coming from the ‘Y’

fitting on the vacuum tube

assembly (Fig. 27). Remove

the pressure line (PN 730130)

with a 7/16" open-end wrench.

Using a pair of needle nose pli-

ers, remove the sleeve clamp

(PN 730015) and clear tube

(PN AA-94C) coming from the

relief valve assembly. Remove

the two screws (PN 510309) holding the venturi body (PN

461851) to the bracket (PN 461869) with a 3/32" Allen

wrench. To repair the venturi, remove the barb fitting (PN

730062) and gasket (PN 730074) from the elbow fitting (PN

730351-01) with a ¼" wrench. Then, follow the same proce-

dure shown above for the right venturi to remove the elbow

and nozzle, and to clean out the orifice in the nozzle.

Figure 23

Tank Drain

Line

Figure 24

Check Valve

Tee

Figure 25

Relays

Tube

Figure 26

Pressure

Line

Venturi

Muffler

Vacuum

Tube

Figure 27

Pressure

Line

Clear

Tube

Vacuum

Tube

Right

Venturi

Muffler

DISASSEMBLY - Continued