5

CHIMNEY CONNECTION

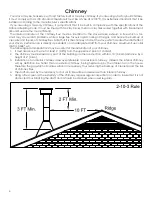

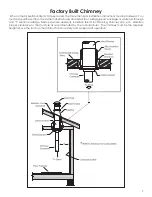

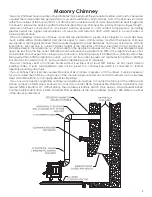

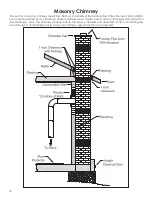

Two basic types of chimneys are approved for use with solid fuel: Factory-built and masonry. Factory-built

chimney must comply with UL 103 type “HT” standard.

Do not expect your stove or furnace to create draft. Draft is not a function of the appliance. It is purely a function

of the chimney. Modern stoves and furnaces are much more air-tight and efficient than those of the past and,

therefore require greater draft. A minimum of .05 w.c. (12.45Pa), is required for proper drafting to prevent back-

puffing, smoke spillage, and to maximize performance. Gauges to measure chimney draft are readily available

at stove shops and are economical to purchase or rent.

Chimneys perform two functions - one of which is apparent: The chimney provides a means for exhausting

smoke and flue gases resulting from combustion of the fuel. Secondarily, though, the chimney provides “Draft”

which allows oxygen to be continuously introduced into the appliance, so that proper combustion is possible.

IMPORTANT

Your chimney connector and chimney must have the same diameter as the stove outlet (6”). If this is not the

case, we recommend you contact your dealer in order to insure there will be no problem with the draft.

The stove pipe must be made of aluminized or cold roll steel with a minimum thickness of 0.021” or 0.53 mm. It is

strictly forbidden to use galvanized steel.

Your smoke pipe should be assembled in such a way that the male section (crimped end) of the pipe faces

down. This will allow condensation in the flue to run back into the heater. Attach each of the sections to one

another with three equidistant metal screws and seal each joint with furnace cement.

The pipe must be short and straight. All sections installed horizontally must slope at least 1/4 inch per foot, with

the upper end of the section toward the chimney.

To insure a good draft, the total length of the coupling pipe should never exceed 8’ to 10’ (2.4m to 3.04 m).

(Except for cases of vertical installation, cathedral-roof style where the smoke exhaust system can be much

longer and connected without problem to the chimney at the ceiling of the room).

It is recommended that no more than two 90 degree bends be used because it may reduce the amount of

natural draft. The use of corrugated (non-adjustable) elbows is preferred as they are much more airtight.

You must have at least 18 inches of clearance between any horizontal piping and the ceiling.

The pipe cannot extend into the chimney flue.

The chimney connector must not pass through an attic, roof space, closet, any concealed space, floor, ceiling,

wall or combustible construction. Where passage through a wall or partition of combustible construction, the

installation must conform to CAN/CSA-B365, Installation Code for Solid-Fuel-Burning Appliances & Equipment.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.