8

Venting Into A Fireplace

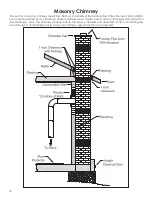

Many people may wish to convert an existing fireplace to heater use. Usually, safe connection of stovepipe to

a masonry chimney requires more effort than connection to a prefabricated chimney. The fireplace must be

closed and sealed at the damper in the flue. Good sealants are high temperature caulking, ceramic wool, and

furnace cement. Always remember to inspect the masonry chimney and fireplace. If necessary, clean the flue

and smoke shelf before beginning your installation. Install the heater into the chimney so that the system can be

dismantled for cleaning and inspection.

Before deciding to convert your fireplace or existing chimney, keep in mind that older fireplaces and their

chimneys are unsafe. They must be structurally sound, and the flue liner must be in good condition. Do not use a

chimney if it is unlined (should have a tile clay liner to protect brickwork), have it relined professionally. Clearances

to combustibles are explained in the previous section on masonry chimneys. If you have any questions regarding

the condition of the chimney, consult a qualified engineer, competent mason, certified Chimney Sweep, or

knowledgeable inspector.

Many prefabricated fireplaces fall into the “zero-clearance fireplace” category. This is a factory metal fireplace

with multi-layered construction. It is designed to provide enough insulation and/or air cooling so that the base,

back and sides can be safely placed in close contact with combustible floors and walls. Although many

prefabricated fireplaces have been tested by nationally recognized organizations for use as fireplaces, they

have not been tested to accept heaters. In fact, their use as such may void the manufacturer’s warranty.

Steel-lined fireplaces, on the other hand, can be used with heaters. These units use a 1/4-inch fire box liner and

an air chamber in connection with 8 inches of masonry to meet code. They contain all the essential parts of a

fireplace, firebox, damper, throat, smoke shelf, and smoke chamber. Many of them look exactly like a masonry

fireplace and must be checked closely for above requirements before installing a coal heater into them.

Another method frequently used by some people is to vent the heater directly into the fireplace. This does not

meet code since the heater is being vented into another appliance - the fireplace. This method should not be

attempted because combustion products will deposit and build up in the firebox or fireplace. Be certain not to

install a hazard in you house. You will void your warranty with this installation.

Connection of the stovepipe directly into the existing masonry chimney over the fireplace opening is the only

approved method. This installation performs better, yielding easy to clean and inspect for creosote. Before

beginning this type of installation plan carefully; a high degree of skill is required to insure safety.

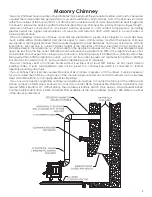

An entry port for the stovepipe must be cut through the chimney with minimum damage to the fire clay liner.

Some involved measurements may be required to locate the flue liner exactly. Before cutting, take time to mark

the size and position of the entry port. Position the entry port so that at least 8 inches of the flue liner remains below

the port.

Keep in mind that wood mantels and combustible trim around the fireplace must have adequate clearances

from the heater and stovepipe or must be protected in an approved manner. Also, be sure to leave at least

24” clearance between the top of the stovepipe and the combustible ceiling or other combustibles. Placing

the center of the entry port 2 feet below the ceiling will insure proper clearance for 6 inch, 8 inch, and 10 inch

stovepipes. Next, install a fire clay (at least 5/8 in. thick) or metal thimble, being sure that the thimble is flush with

the inner flue lining. Secure the thimble in place with refractory mortar. The thimble should be surrounded on all

sides with 8 inches of brickwork (solid masonry units) or 24 inches of stone.

Install the stovepipe as far as possible into the thimble, but not past the inside of the flue lining. There should

be a small air space (approximately 1/2 in.) between the stovepipe and thimble, allowing for expansion of the

stovepipe. Seal this airspace with high-temperature caulking or ceramic wool. Finally, be sure to wire the damper

closed and apply the same sealant you used at the stovepipe and thimble junction.

Do not vent up through the fireplace opening, regardless of whether the fireplace opening is closed.