9

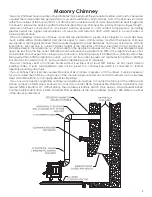

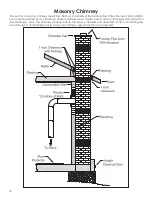

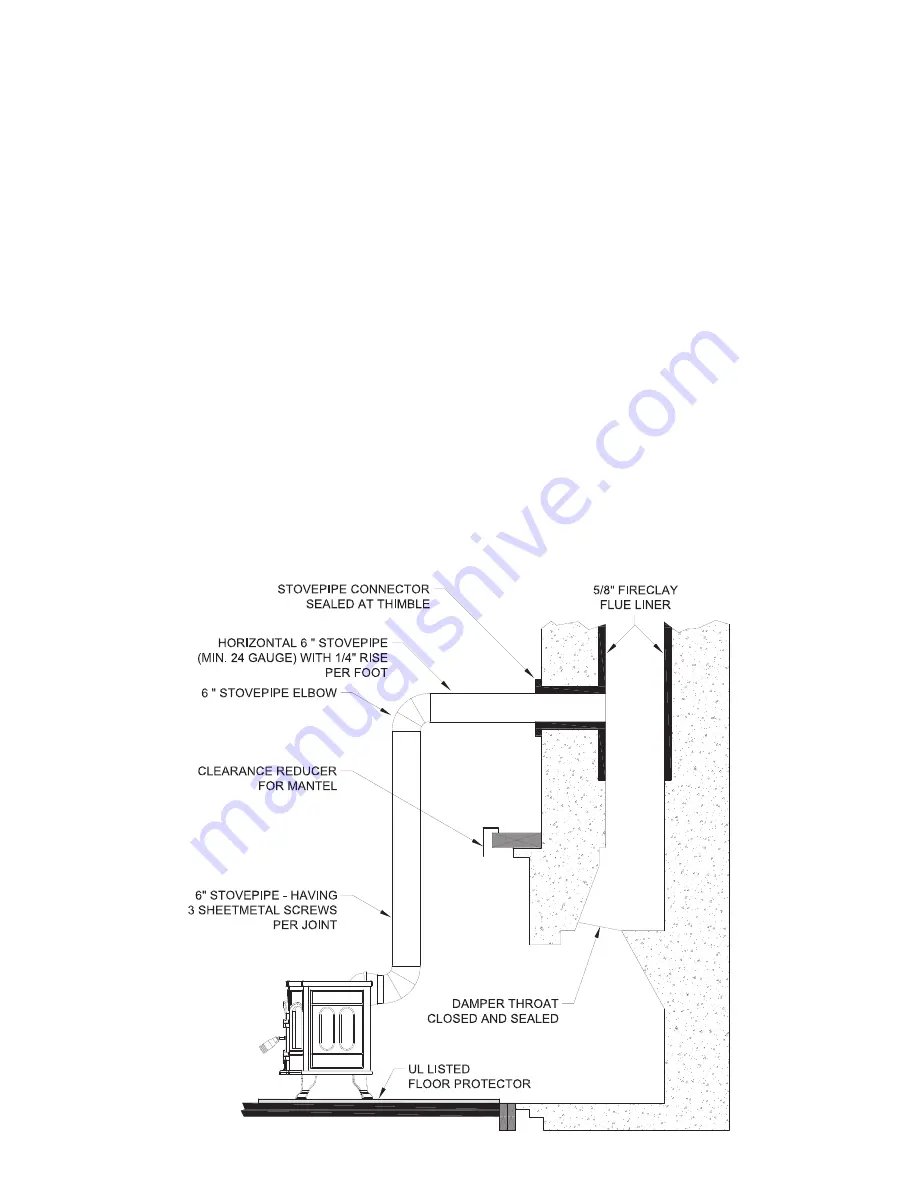

Masonry Chimney

Masonry Chimneys have several positive attributes: If properly built, they are quite durable, and most homeowners

consider them more attractive perhaps than a non-enclosed factory built chimney. And, if the chimney is located

within the confines of the house (that is, not attached to an exterior wall), its mass alone will store heat longer and

continue to release the heat long after the fire has died. Masonry chimneys have many disadvantages though.

Masonry chimneys constructed on an exterior wall are exposed to cold outdoor temperatures, promoting

greater heater loss, higher accumulations of creosote, and reduced draft which leads to poorer heater or

furnace performance.

When considering a masonry chimney, round tiles are preferable to square or rectangular, as round tiles have

much better airflow characteristics and are far easier to clean. Unfortunately, most North American chimneys

use square or rectangular tile liners that are really designed for open fireplaces, not stoves or furnaces. Of most

importance, second only to overall chimney height, is the diameter of the flue liner itself. In most instances, it

should be sized to the appliance; i.e., 6” flue outlet on the appliance requires a 6” flue. The inner diameter should

never be less than the flue outlet diameter and should never be greater than 50% of the appliance flue outlet.

For example, do not expect a burning stove or furnace to function properly if installed into a chimney with a flue

liner greater than 50% the appliance outlet -- such as a 6” flue outlet requires a 6” diameter for optimum drafting,

but can function well with an 8”, but becomes borderline beyond 8” diameter.

Masonry chimneys built of concrete blocks without flue liners of at least 5/8” fireclay do not meet modern

building codes. A solid fuel appliance must not be joined to a chimney flue which is connected to another

appliance burning other fuels.

If your chimney has a typically oversized flue liner of 8x12 inches or greater, or if it is unlined, it will be necessary

for you to reline the chimney, using many of the modern approved and economical methods such as stainless

steel, castable refractory, or properly sized fireclay linings.

If you have any question regarding venting your appliance, feel free to contact the factory at the address and

phone number on this Owner’s Manual. You may also contact NFPA (National Fire Protection Association) and

request NFPA Standard 211 (1984 Edition). Their address is Battery March Park, Quincy, Massachusetts 02269.

Another helpful publication is NFPA Standard 908, available at the same address. Specify 1984 Edition on either

of the above publications.