ASI Dental Specialties

7 – TROUBLESHOOTING

www.asisupport.com

Page 1

65-0057 Rev-A (11/12/20)

BASIC TROUBLESHOOTING GUIDE

The following information is intended to assist with some common issues that could arise with the dental

system. Many issues can be resolved or repaired without any special equipment or training.

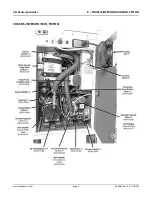

Troubleshooting the Delivery Unit

The system should be maintained and given proper care. If something does go wrong, the information contained

herein explains what can be done prior to arranging for or attempting repairs. Additional information may be

available in Technical Guides covering the individual components located on the dedicated website

ASIsupport.com.

Handpiece or Instrument does not Operate

•

Verify the lock-out lever on side of the holder is pointing straight down to the floor and that the ball

actuator in the base of the holder has activated out.

•

Make sure the correct adjustment stem on the control block portion for that handpiece has been

opened to allow air to flow to the handpiece or activation switch for electric instruments.

Not Enough Pressure to the Handpiece

•

Low pressure from compressor or regulator in junction box. Check air tank pressure gauge. Ensure 75 to

80 psi prior to adjusting handpiece block.

•

Make sure the correct adjustment stem on the control block portion for that handpiece has been

opened.

•

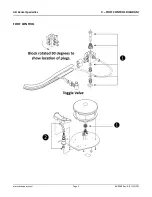

Ensure that the exhaust air tubes and oil mist recovery jar are allowing the air to exhaust freely. Verify

that there is no kinked exhaust tubing to the oil mist recovery jar or any obstructions such as cotton

two-by-twos in the exhaust port of the jar lid.

•

Ensure that only one air-driven handpiece is being lifted out of the holder at one time. If multiple

handpieces are in use, the pressure will decrease on each of them.

•

Diaphragm(s) in control block may need to be replaced if over five years old or if the system has been

over pressurized.

o

Order ASI PN 95-0215,

Control Block Diaphragm Pucks Full Set

and refer to the applicable

technical guideline (located on ASIsupport.com) for more information.

•

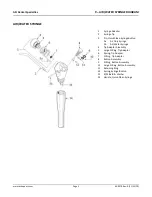

Check to be sure the handpiece gaskets are secure. These are located on the back end of the handpiece

or the swivel coupler. The handpiece tubing nut also needs to be firmly tightened onto the handpiece in

order to seal against this gasket.

•

Make sure the bulkhead gasket is secure where it connects to the delivery system and there are no

cracks.

•

Check for kinks in the foot control tubing. The air that runs the handpiece is coming all the way from the

foot control. Any kinks or bends can restrict the air and limit the pressure.

•

A worn-out handpiece consumes more air to operate than a new one. Check to see if the turbine is the

problem by switching to another handpiece and checking the pressure. Follow handpiece

manufacturer’s recommendation for repairing handpiece.

65-OS01 Rev-A | 11/12/20