it into the hammer drill.

Push the protective cover back and install the tool.

At the same time, push it until it is attached.

Loosen the cover (1) and pull the tool tentatively.

Make sure it is locked in place.

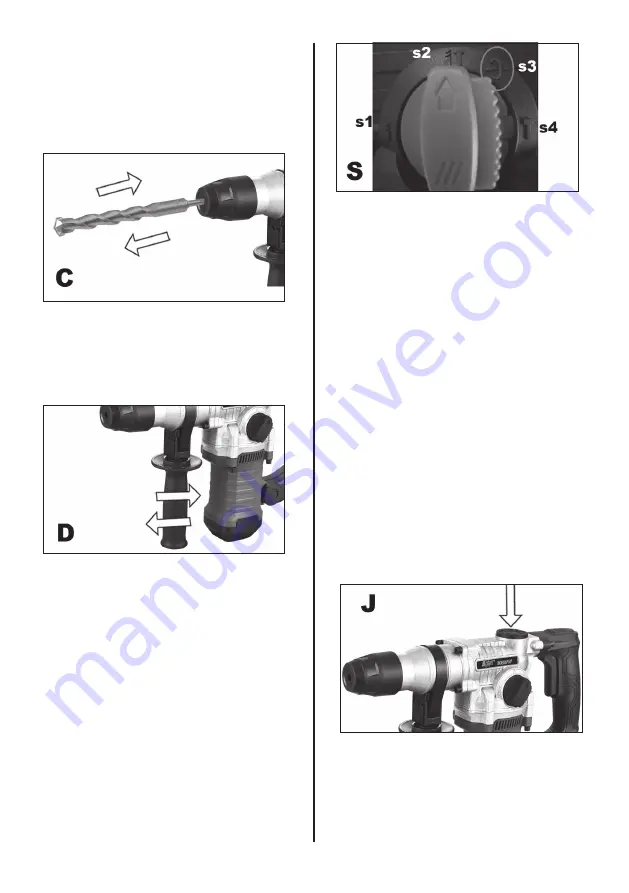

Tool removal (C)

Push the protective cover (1) back. Then pull out the

tool.

Handle attachment (D)

For safety, use an electropneumatic hammer drill with

an auxiliary handle.

You can adjust the handle to the required position.

This ensures a safe body position during drilling.

Release the handle by turning it counterclockwise, set

the desired position, then tighten the handle

Choice of operating mode

This tool has a total of 4 functions.

These functions are:

1st drilling / S1 /

2. hammer drilling / S2 /

3. chopping / S4

4. fl at chisel rotation / S3 /

(can rotate horizontally or vertically)

The switch (5) can be used to set the type of operat-

ing mode.

Adjustments with the rotary knob must not be

made while the machine is running (only after it

has stopped), otherwise it will be damaged.

Damage due to improper handling is not covered

by the warranty.

CLEANING AND MAINTENANCE

! Always unplug the tool before cleaning and mainte-

nance.

There are no serviceable parts inside.

Never use water or chemical cleaners to clean your

tools. Wipe it with a dry cloth.

Keep the motor fan grille clean.

If you see a very faint spark in the engine compart-

ment, your tool is OK. Increased sparking is a fault in

the engine.

Never clean any part of the tool with a hard, sharp or

rough object.

It is advisable to use compressed air to remove dust.

Check the carbons regularly (for cleanliness and

wear). Dirty or worn carbons cause excessive spark-

ing and reduced power / speed.

Gear lubrication (J)

! Before using the tool, always make sure that there is

enough lubricant in the gear unit.

Check the lubricant level at least every 5 hours of

operation.

Use the key provided to open the gear unit by remov-

ing the lubrication hole cover (4).

If necessary, top up with lubricant - the supplied prod-

uct or the same. Use grease for bearings or gears, eg

NH3. Do not use graphite grease!

Replace the cover (4) and tighten the key.

Storage when not used for a long time

Do not store the tool in a place where the temperature

is high.

If possible, store the tool in a place with a constant

temperature and humidity.

35

Summary of Contents for AE1K105DM

Page 4: ...4...

Page 60: ...www rs we com...