1 - The welding machine is checked against any defects before leaving the factory. Therefore, do

not allow unauthorized persons to tamper with the machine.

2 - The repair works must be carried out only by the “Authorized Technical Services” allowed by

Kaynak Tekniği Sanayi and Ticaret A.Ş.

3 - Watch out for the air pressure while cleaning in order to protect the smaller components. Never

direct water into the machine for cleaning.

4 - The welding machine should not be cleaned with volatile and synthetic cleaners. Use a moist

and soapy piece of cloth for cleaning the exterior.

5 - The maintenance works must be carried out with care. Kinking or wrong connection of a cable

may be very dangerous for the user.

6 - Ingress of water or steam should not be allowed in to the welding machine. If the machine might

be affected by humidity, the interior must be dried and the insulation re-checked.

7 - The welding machine should be protected against tossing around while lifting and protected

against impacts.

8 - If the welding machine is to be stored for a long time, place it in the original box and store in a dry

place.

working environment and conditions, it is necessary to check whether there is oil and other

liquid accumulation in the machine in monthly periodic periods and if necessary, they

should be cleaned.

Check the screws on the machine, loose ones must be tightened. If any screw is missing

put a new one. Replace the rusty screws.

QUARTER YEARLY MAINTENANCE

Check the welding current delivered by the machine is equal to the value adjusted with the

potentiometer. Measure the actual current value with a clamp-type ammeter.

YEARLY MAINTENANCE

Contact to authorized service for yearly maintenance. Grounding continuity and

insulations test must be applied during yearly maintenance. Check if this tests has been

done from the yearly maintenance report.

Maintenance and Troubleshooting - 2

USER

MANU

AL

63

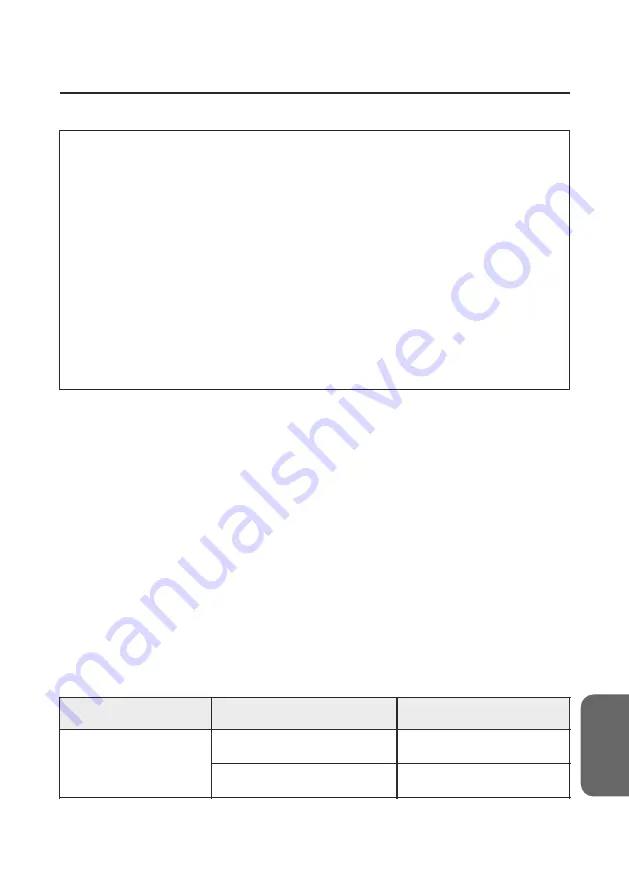

PROBLEM

POSSIBLE REASON

SOLUTION

The welding current

displayed isn’t accordant

with the actual value.

The min. value displayed isn’t

accordant with the actual value.

Adjust potentiometer “Imin”

on the power board.

The max. value displayed isn’t

accordant with the actual value.

Adjust potentiometer “Imax”

on the power board.

Summary of Contents for 315-TIG Pulse

Page 2: ......

Page 16: ...Çalışmaya Hazırlık 2 ÖN PANEL KULLANIM KILAVUZU 14 1 7 4 5 6 2 3 ...

Page 17: ...Çalışmaya Hazırlık 3 ARKA PANEL 8 9 10 KULLANIM KILAVUZU 15 ...

Page 32: ...Yedek Parçalar 1 KULLANIM KILAVUZU 30 ...

Page 42: ...KULLANIM KILAVUZU ...

Page 56: ...Preparation for Work 2 USER MANUAL 54 FRONT PANEL 1 7 4 5 6 2 3 ...

Page 57: ...Preparation for Work 3 USER MANUAL 55 REAR PANEL 8 9 10 ...

Page 72: ...Spare Parts 1 USER MANUAL 70 ...

Page 76: ...USER MANUAL ...

Page 77: ......