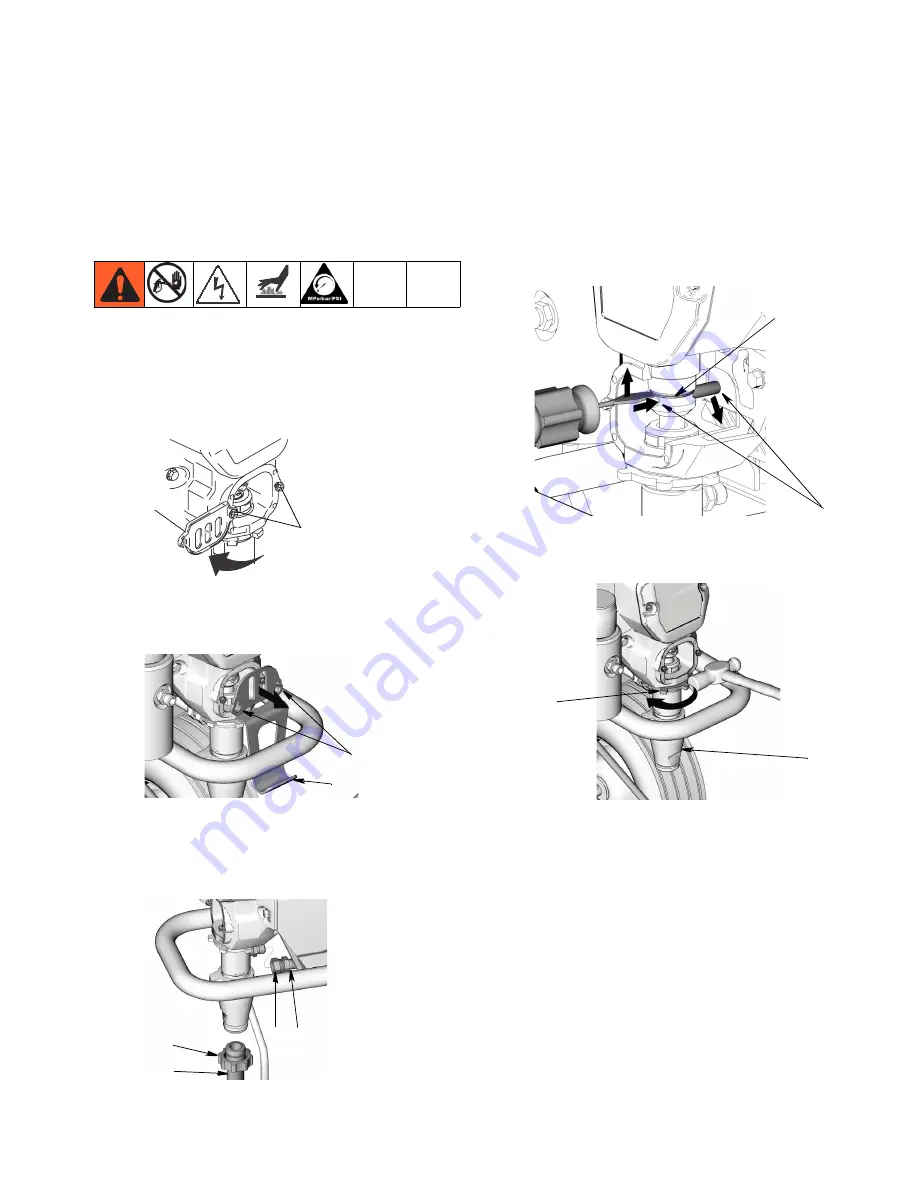

Displacement Pump Replacement

332763A

17

Displacement Pump Replacement

See manual 312362 for pump repair instructions.

Removal

1.

Relieve pressure

, page 9. Unplug sprayer from

outlet.

2.

Style A:

Loosen two screws (30) and rotate cover

(44).

Style B:

Loosen two screws (30). Push cover (44)

up and remove from sprayer.

3.

Loosen nut (95) and remove suction hose (35).

Loosen nut (B) and remove the high pressure hose

(14).

4.

Cycle pump until pin (8) is in position to be removed.

5.

Disconnect power cord from outlet.

6.

Push up retaining spring (7a). Push out pump pin

(8).

7.

Loosen pump jam nut (10). Unscrew and remove

pump (9).

Style A

TIA

30

44

11

10

ti9138a

Style B

14

B

95

35

ti9139a

7a

8

ti9040a

10

9

ti9141a

Summary of Contents for 24U099

Page 33: ...Notes 332763A 33 Notes ...

Page 39: ...Notes 332763A 39 Notes ...