16

309423

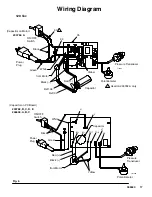

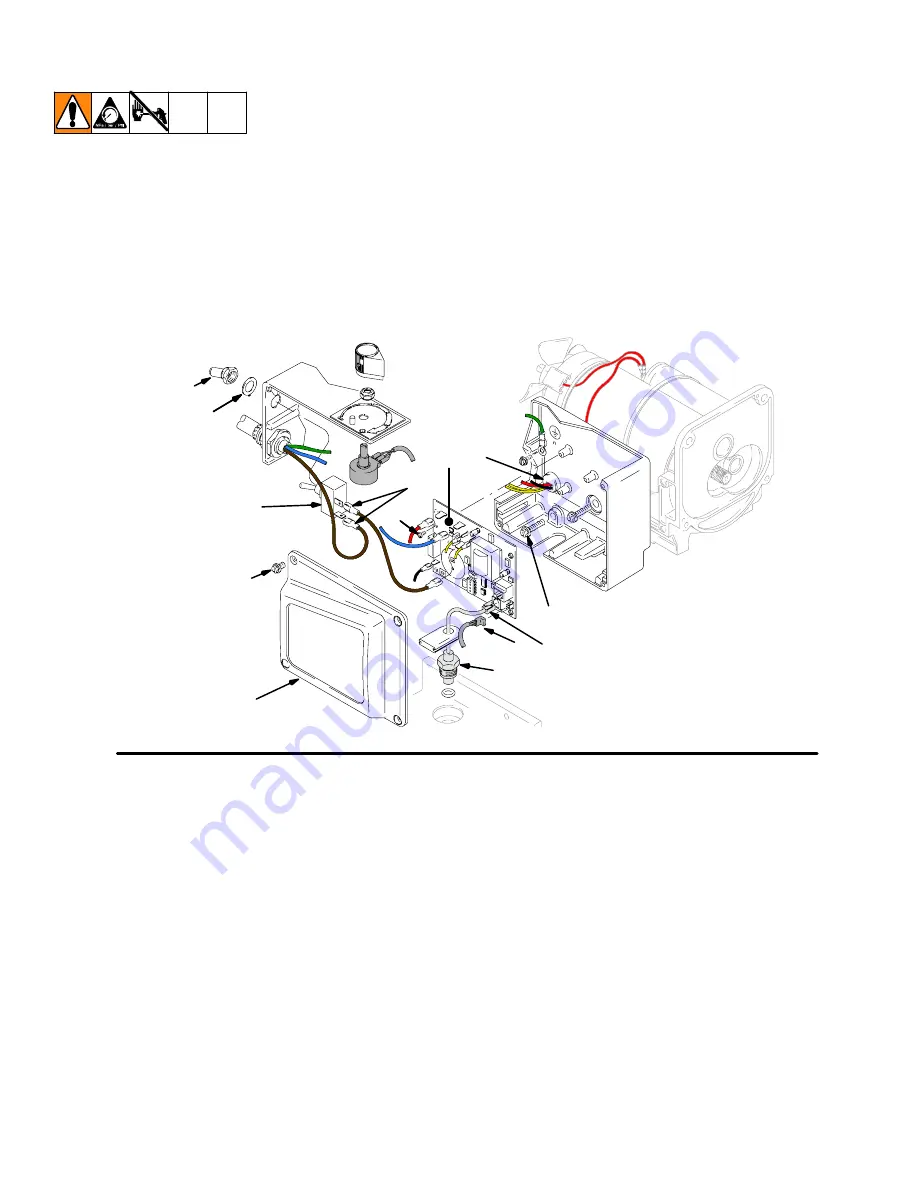

On/Off Switch Replacement

Removal

1.

Relieve pressure;

page 8.

2. Fig. 5. Remove four screws (18) and pressure

control cover (39).

3. Disconnect two wires (A) from ON/OFF

switch (23).

4. Remove toggle boot (25) and locking ring (24).

Remove ON/OFF switch (23).

Installation

1. Install new ON/OFF switch (23). Install locking ring

(24) and toggle boot (25).

2. Connect two wires (A) to ON/OFF switch.

3. Install pressure control cover (39) with four

screws (18).

Fig. 5

39

A

18

23

36

52

E

D

35

36

25

24

37

22

ti3917a

Summary of Contents for Zip-Spray 1900 Plus

Page 27: ...27 309423 Notes ...

Page 43: ...43 309423 Notes ...