EFD1000 E5 Dual Electronic Flight Instrument (EFI) Install Manual

DOCUMENT # 900-00041-001

PAGE 57-226

REVISION D

© Copyright 2019 Aspen Avionics Inc.

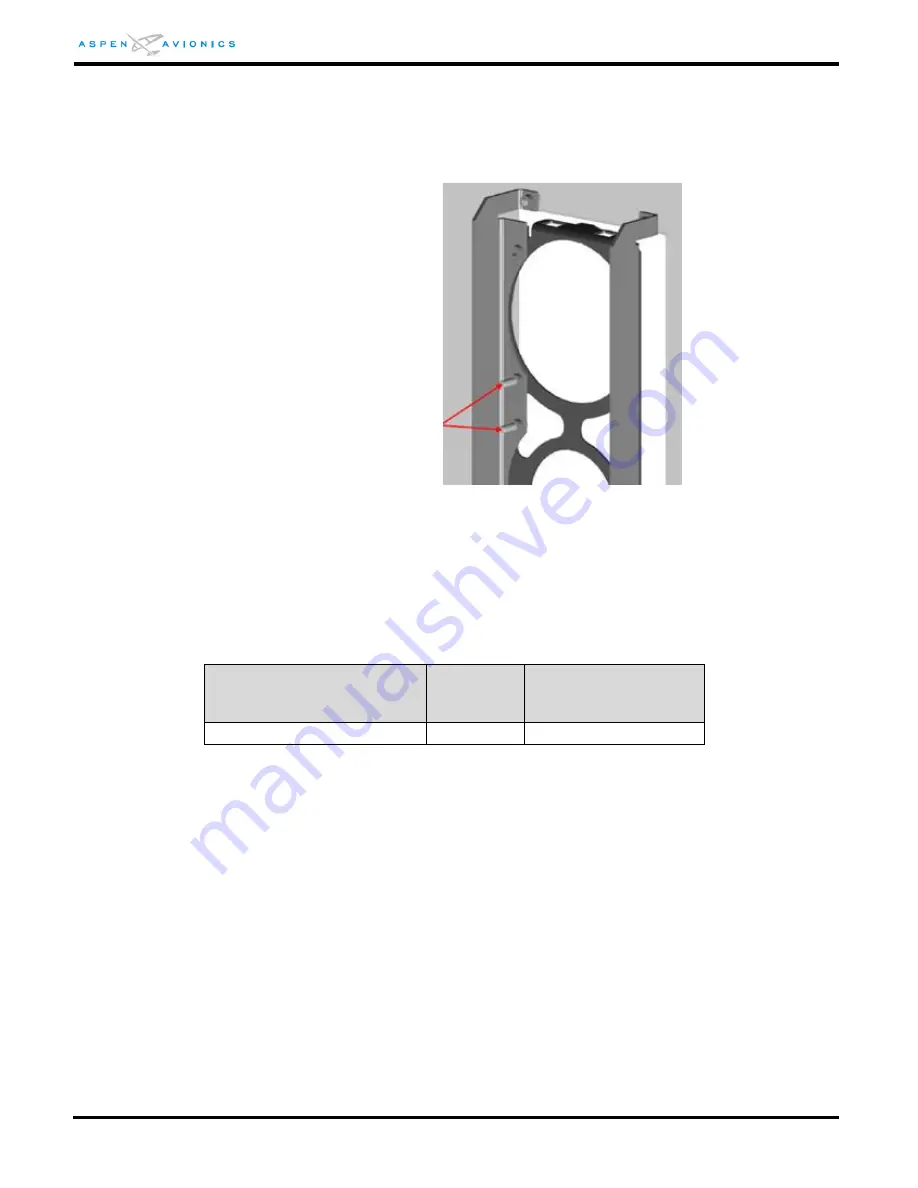

2)

Insert a MS24693-S30 6-32 x ¾” flat head machine screw through either an

unused threaded insert or an existing EFD bracket attachment screw (see

Figure 6-5). Attach one end of the ground strap to this screw using a

MS21044N06.

Figure 6-5: Ground Strap Attachment Points

STEP 8 – Perform the Structural Load Test on the Bracket Installation

The following test is to structurally substantiate the bracket installation. The applied

static test load is determined using 2.9lbs for the EFD mass. See AC 43.13-2B for

additional Structural Data.

Direction of Pull

(push on bracket)

Load

Factor

Static Test Load

(load factor x EFD

weight)

Forward (toward firewall)

9.0g

9.0 x 2.9 = 26 lbs

Table 6-3: Static Load Table

Use a block of wood or piece of aluminum that will cover the EFD bracket. This

ensures an even force is applied to the entire bracket at once. Place mechanical or

digital push/pull gauge against block and assert the static test load defined in the

table above for a minimum of 3 seconds. Ensure instrument panel and brackets show

no signs of permanent deformation.

NOTE: The recessed brackets are TSO’d and meet the sideward, upward, downward, and forward axis

load requirements of the EFD. Therefore only the forward axis is tested above to substantiate

the overall bracket installation.

Location of 6-32 X ¾” screw

for ground strap attachment