EFD1000 E5 Dual Electronic Flight Instrument (EFI) Install Manual

DOCUMENT # 900-00041-001

PAGE 73-226

REVISION D

© Copyright 2019 Aspen Avionics Inc.

4)

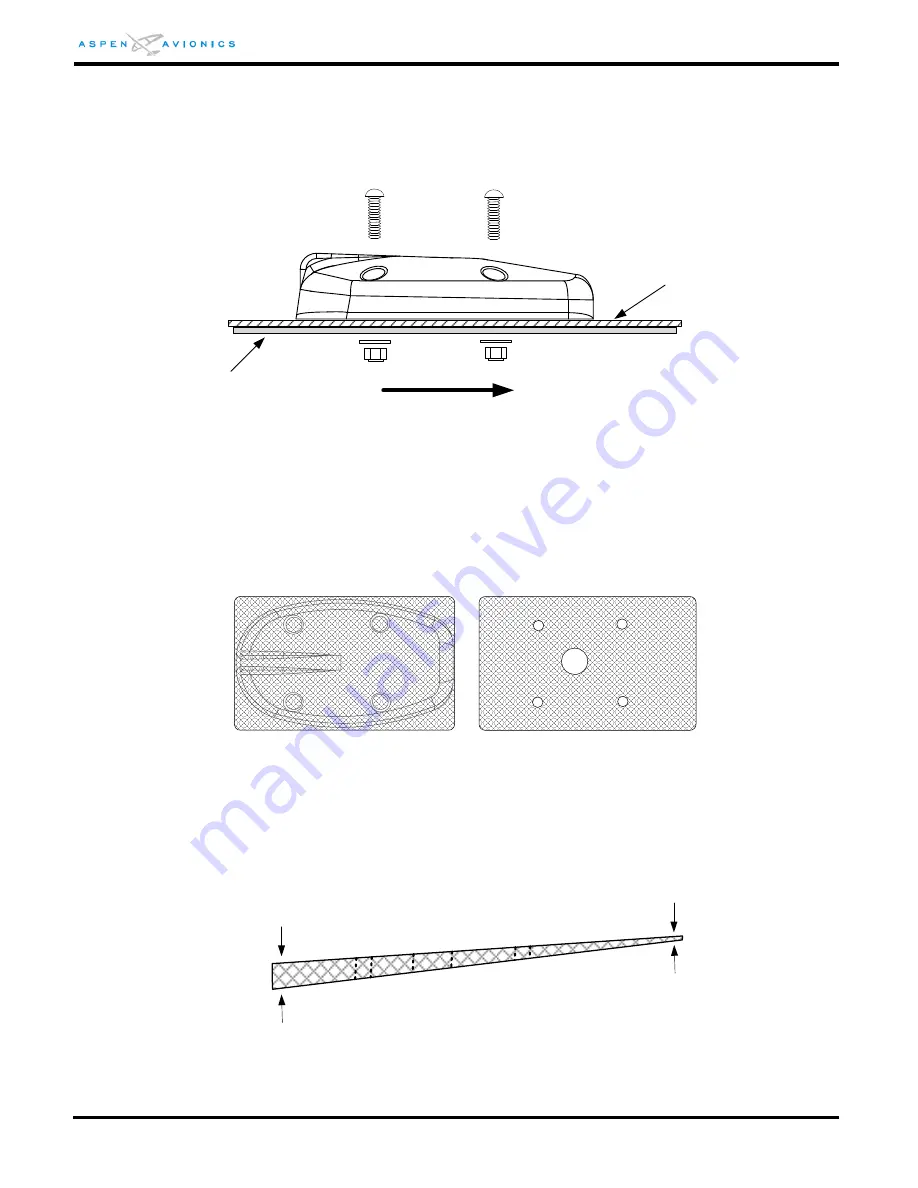

Torque hardware to 12-15 in-lbs. Do not over-torque the hardware as it may cause the

RSM housing to crack.

5)

Attach ring terminal to ground stud on RSM doubler tab.

6)

Apply a bead of non-corrosive sealant around the RSM.

Figure 6-22: RSM Mounting

6.9.11

RSM Shim Fabrication (if necessary)

If the RSM exceeds the mounting limits of Section 6.9.7 a shim will be required.

Fabricate a shim with the dimensions of the RSM baseplate. Optionally the shim can be

made square and slightly larger than the RSM baseplate for ease of construction (see

Figure 6-23).

Figure 6-23: Example Shim Top View

The shim must not exceed the minimum and maximum thickness as shown in Figure

6-24. Use of a thicker shim is acceptable but not approved under this STC. A thicker

shim will require a local approval.

Figure 6-24: Example Shim Side View

Doubler

(installer fabricated)

Aircraft Skin

FWD

No Thinner than 0.040"

No Thicker than 3/8"