EFD1000 E5 Dual Electronic Flight Instrument (EFI) Install Manual

DOCUMENT # 900-00041-001

PAGE 74-226

REVISION D

© Copyright 2019 Aspen Avionics Inc.

1)

Use RSM doubler as a template to mark shim stock.

2)

Fabricate shim from 2024-T3 aluminum with the four (4) mounting holes and 0.625”

cable pass-thru drilled through.

3)

Remove burrs and break sharp edges (0.005” – 0.015”)

4)

Finish with Alumiprep Etch and Alodine Conversion Coating.

5)

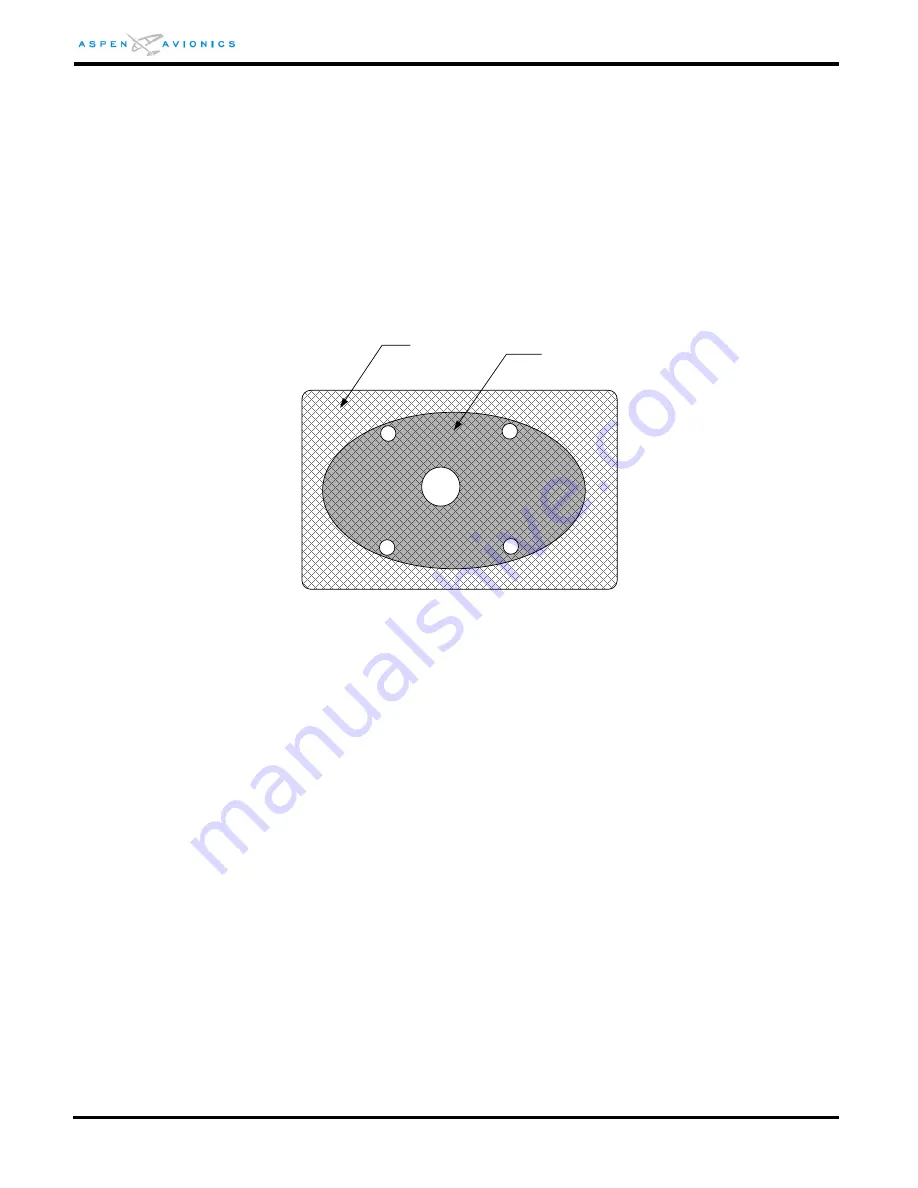

Mask off top side of shim 1/4” inside mounting surface of RSM and mask off a similar

area on the bottom so that these areas remain Alodine only (see Figure 6-25). Prime

unmasked areas with epoxy primer per MIL-P-23377. Paint to match aircraft color if

desired.

Figure 6-25: Masking of Shim for Priming

6)

The shim must be bonded to the aircraft skin by removing the paint and prepping the

aircraft surface where the shim and RSM will be mounted. Remove paint ½” inside the

outer footprint of the RSM mounting location. Burnish the aircraft skin and apply Alodine

1201, do not prime.

7)

Sandwich the shim between the aircraft skin and the RSM following the RSM installation

procedure in Section 6.9.10.

8)

Apply non-corrosive sealant around shim and RSM.

6.10

ACU/ACU2 Installation

The ACU/ACU2 has no user interface, and therefore can be remote mounted. The optimum

mounting location is an area that minimizes wire runs to interfacing equipment. This typically

means near the autopilot computer if installed.

When mounting the ACU/ACU2 find a location in the aircraft of known load carrying

capabilities such as:

Existing Avionics Shelf

Baggage compartment

Radio Rack

Cockpit Floor

Epoxy Primer

Both Sides

Do not Prime

Mask Off

Both Sides