53

EN

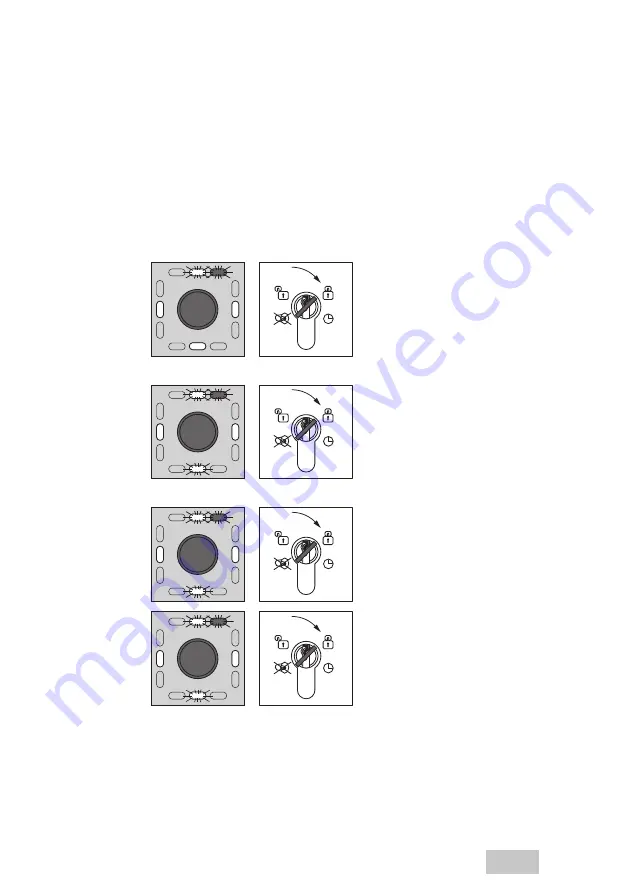

Configuration

Master/Slave

In the

Master/Slave

configuration menu of the escape door terminal 1385, the

LEDs show which slaves are online, offline or in address conflict.

Display devices on the bus

6

5

4

1

2

3

7

8

ge rt

The LEDs 1 to 8 indicate the address

(LED1 = 1, LED2 = 2,...) where a device on

the bus has detected the master.

Show address conflict

6

5

4

1

2

3

7

8

ge rt

If one of the devices has a problem (gone

offline, address conflict), the correspond-

ing LED will flash.

Remove address conflict

6

5

4

1

2

3

7

8

ge rt

1 Push the key to the right:

The display is updated when the key

is released

If the address conflict still exists, it

must be resolved.

6

5

4

1

2

3

7

8

ge rt

10 s

10 s

1 Turn the key to the right and hold it

for 10 seconds.

After five seconds, a beep will be

heard every second.

A long acknowledgement signal is

emitted after ten seconds.

If the key is turned to the right for more than ten seconds, the address conflict is

eliminated and the bus is scanned again.