O

PERATIONAL

S

PECIFICATIONS

Card Compatibility

Prox

:

All HID (125kHz) Prox credentials

iCLASS

:

All

iCLASS

(13.56MHz)

credentials

Electrical Specifications

Power Requirements

Voltage In: 12Vdc (Range: 10.8Vdc –

(Prox/iCLASS):

16Vdc)

Current Consumption: 150mA average,

300mA peak

Transmit Frequencies:

Prox – 125kHz

iCLASS – 13.56MHz

Environmental Specifications (Prox/iCLASS)

Operating Temperature

-31° to 150°F (-35° to 65°C)

Operating Humidity

5% to 95% relative humidity non-

condensing

Wiring Connections (Prox/iCLASS)

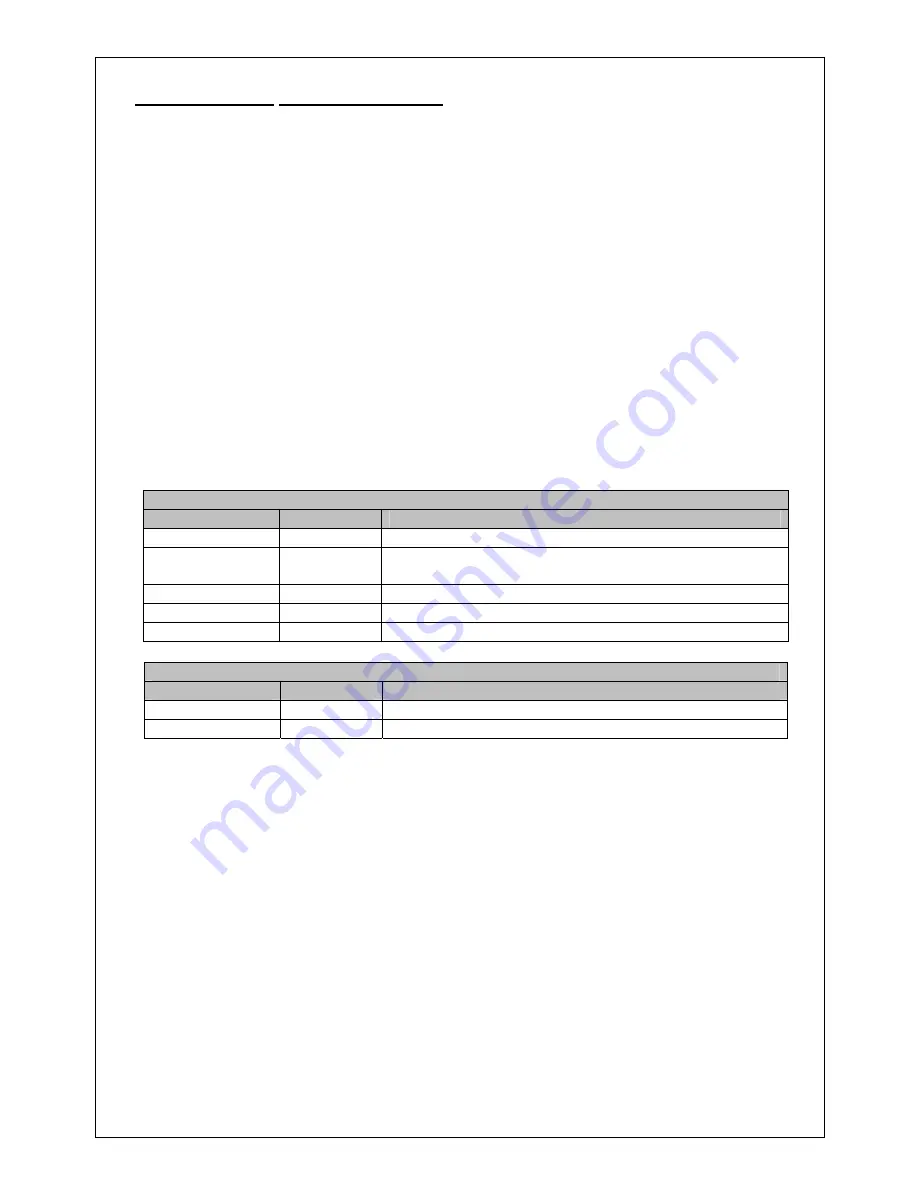

E-Lynx Cable Pin Out

8 – PIN E-Lynx Connector

Molex Pin #

Color

Description

1 Black

System

Ground

5

Red

Reader/Motor Controller Power

(+12Vdc, 300mA Max)

2 White

Weigand

Data

1

6 Green

Weigand

Data

0

8 Yellow

Green

Led

Control

4 – PIN E-Lynx Connector

Molex Pin #

Color

Description

1 Violet

System

Ground

3

Gray

Lock Activate (+12Vdc, 10mA Max)

Lock Activate Signal – (+12Vdc, 10mA Max)

N.O. relay (or other isolated source) output from access control system

that a12Vdc to this pin when valid credentials were accepted by

the access control system. As long as this signal is active (+12Vdc) the

lock will remain in an unsecured state, which will allow the lever to

retract the latch/bolt. This line needs to return to 0Vdc in order for the

eForce

®

to return to a secured state.

Recommended Cable Information

1.

Cable Size – 28 AWG minimum, stranded 7/36

2.

Cable Distance – 500 feet maximum

3.

Cable Type – 300V minimum, PVC insulation or better

4

80

‐

0180

‐

327

Rev.

A