14

IN100 Cylindrical Lock

Copyright © 2016 Corbin Russwin, Inc., an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the

express written permission of Corbin Russwin, Inc. is prohibited.

5) Installation Instructions (Continued)

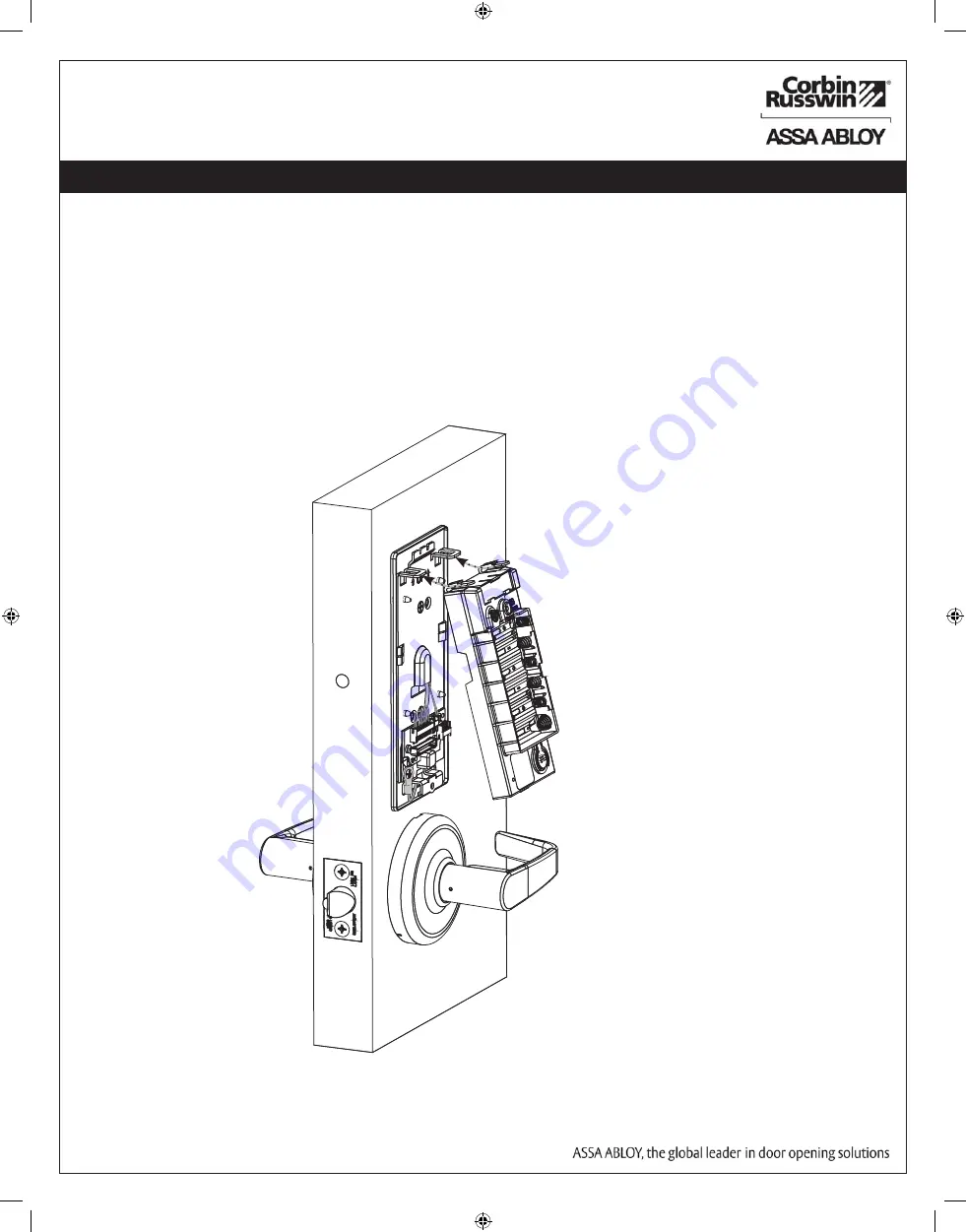

11. Installation of Inside Component Assembly

a. Insert top tabs of controller into slots on mounting plate (Fig. 11).

b. Ensure proper alignment of board-to-board connectors while pivoting bottom of controller

toward door until tab on bottom snaps securely into place on mounting plate.

CAUTION: To avoid possible damage to board-to-board connectors,

care should be taken when securing controller to mounting

plate. If there is resistance when securing, detach controller

to determine cause before re-attaching controller.

Fig. 11

Inside Face of

Door