32

The warranty on Corbin Russwin products becomes void if the product is modified in any way, regardless of whether the modifications causes or contributes to any alleged defect. If a

Corbin Russwin product is modified it may no longer meet industry certification and quality control standards applicable to the original product and is no longer a genuine Corbin Russwin product.

Copyright © 1999-2018, ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole or in part without the express written permission of ASSA ABLOY Access

and Egress Hardware Group, Inc. is prohibited. Patent pending and/or patent www.assaabloydss.com/patents.

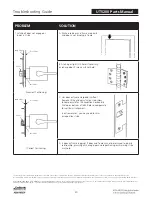

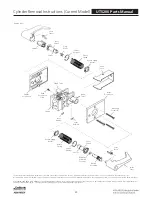

Cylinder Removal Instructions (Current Model)

UT5200 Parts Manual

1. Remove all visible screws from

escutcheons. Push outside escutcheon

away from door surface to clear lugs.

Pull lock from edge of door.

2. If lockset function permits, unlock

lever with button inside or key.

3. Remove chassis cover. Gently pry

edges loose with small screwdriver

while pulling cover away from chassis.

4. Door hand and bevel determine which

escutcheon is fixed.

If outside escutcheon is loose

, pry

lever stop away from frame to

expose crescent-shaped lever retainer

in slot of frame tube. Using small

screwdriver,

pry retainer out of slot.

If outside escutcheon is fixed

, use

offset screwdriver to remove Phillips

head screw, either from inside of

frame or by using access hole in

opposite frame wall.

If no offset screwdriver is available,

loose escutcheon and opposite lever

must be removed to expose access hole

in opposite frame wall for standard

phillips screwdriver. With screw removed

and

escutcheon now loose, pry lever stop

away from frame to expose crescent-

shaped lever retainer in slot of frame

tube. Using small screwdriver, pry

retainer out of slot.

5. For all functions except UT 5282 (

store

door

), skip to step 6. For UT5282,

remove small retainer (

item #30 on

exploded view page

). This can be

challenging so be patient. With small

screwdriver, rotate retainer around

spindle until its opening is in position

of easiest access. Use second small

screwdriver with first screwdriver to

spread

retainer and remove it from spindle.

6. Pull lever handle, return spring and

spring anchor off frame. Since spring

is wound, rotate lever in appropriate

direction to unwind spring. Remove

lever stop from spring.

7. Note orientation of hooks on ends

of spring in illustration. One hook is

engaged in slot in shank. Twist and

“snap” spring to disengage it; then

remove it. If spring bends or deforms,

it must be replaced on reassembly.

Since spring and lever are both

handed, set them aside together.

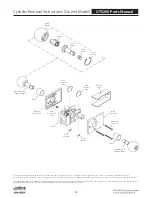

8. Remove gray insert from lever,

(

see illustration

). Using Waldes Tru-

Arc pliers (

Cat. No. CT-27

), remove

retaining ring from groove inside

lever. Remove shank, plug driver and

cylinder.

1. Insert cylinder into lever. Be sure plug

head seats properly in lever. Insert

lever shank, making sure locating tab

on shank flange aligns with slot in

lever.

2. Install Waldes ring, beveled side up,

into groove inside lever. Shank and

cylinder must be properly to ensure

proper engagement of Waldes ring.

Rotate Waldes ring so opening aligns

with notch in shank flange. Opening

must be clear to accept hook of return

spring in Step 3.

3. Install gray insert into lever. Insert

lever return spring, large hook down,

into slot in shank and twist spring to

lock hook into place.

4. Place escutcheon onto lever and

shank.Insert short hook of spring

into slot of lever stop. Holding lever,

spring and lever stop together with

escutcheon, slide lever shank into

frame tube. Align flat on inside of

spring anchor with flat on frame tube.

Wind spring one turn in appropriate

direction, depending on hand. Push

lever and shank assembly into frame

tube until groove milled into lever

shank aligns with slot in frame tube.

5. Press lever retainer firmly into slot. Be

sure retainer seats completely to

secure shank to frame tube. Stake

lever retainer into frame tube slot by

tapping screwdriver or punch into

frame tube next to retainer. Caution:

too much force may deform tube and

prevent smooth lever operation.

6. If both levers were removed, reinstall

second lever, repeating steps 4 and 5.

7. For all functions except UT5282 (

store

door

), proceed to step 8. For UT5282,

small retainer removed in step 2 must

be reinstalled. The can be very difficult

without Waldes ring applicator.

8. If outside escutcheon is to be fixed,

use long nose pliers to start Phillips

screw through frame into escutcheon.

Using offset screwdriver, tighten screw

making sure escutcheon is properly

seated on frame.

9. Test operation of all keys, buttons

and levers. Install chassis cover and

throughbolts.

To Reassemble

Lever Version

Refer to illustration on page 33.

Tools needed:

CT-27 pliers (see page 25), small flat blade

screwdriver, offset or standard Phillips screwdriver, and spare

lever return spring(s) of proper hand of lever(s) to be rekeyed.

Original return spring must often be destroyed to remove it.