37

The warranty on Corbin Russwin products becomes void if the product is modified in any way, regardless of whether the modifications causes or contributes to any alleged defect. If a

Corbin Russwin product is modified it may no longer meet industry certification and quality control standards applicable to the original product and is no longer a genuine Corbin Russwin product.

Copyright © 1999-2018, ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole or in part without the express written permission of ASSA ABLOY Access

and Egress Hardware Group, Inc. is prohibited. Patent pending and/or patent www.assaabloydss.com/patents.

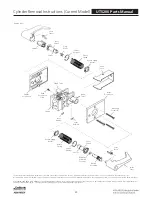

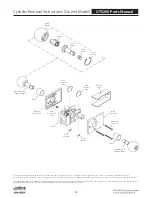

Cylinder Removal Instructions (Discontinued Models)

UT5200 Parts Manual

For Corbin 700/Russwin 1600 Series “Baby” Unit Lock- Horizontal Keyway

Tools needed: 1/8” and 1/4” flat blade screwdrivers, needle nose pliers and a plastic or rawhide mallet.

Caution!

No replacement parts are available for this lock. Be very careful not to damage or distort any parts.

1. Remove all escutcheon screws or thru-

bolts above and below knob on both

sides of door. Loosen thru-bolt on

inside near latch. Pull lock from edge

of door.

2. Remove chassis cover. Gently pry

edges loose with small screwdriver

while pulling cover away from chassis.

3. Observe exposed mechanism on end

of chassis OPPOSITE latch bolt. For

this model, one or two screws pass

through a bracket-shaped steel knob

retainer. If chassis is not constructed

this way, you are reading wrong set of

instructions.

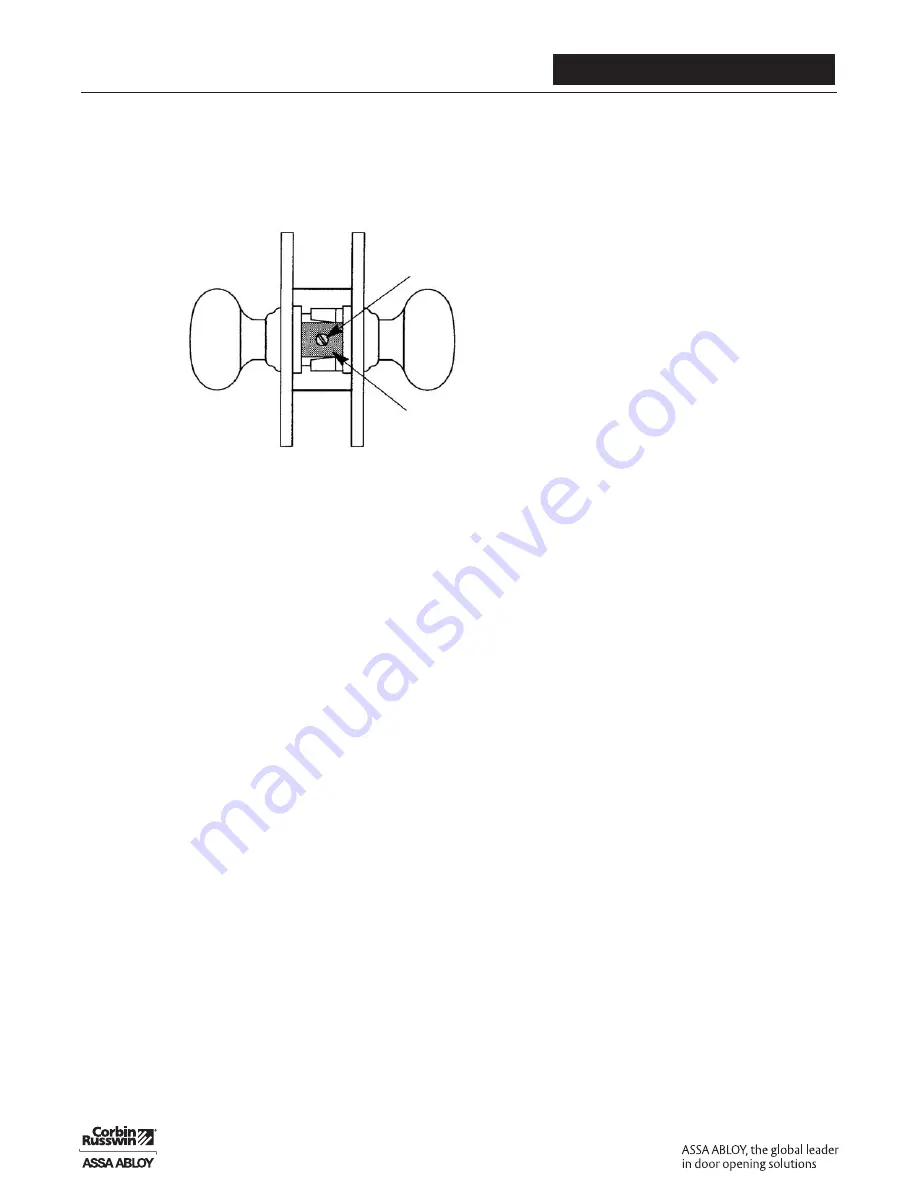

Before removing bracket screw(s), turn

knob(s) and observe orientation of

hubs and any other small parts

directly connected with knob shanks.

These parts may fall out when knob(s)

are removed and you will need to

reinstall them correctly. Make sketch

if desired.

Depending on function of lock,

unlock knob with inside turn button

or by using key. This is not be possible

on storeroom function with rigid

outside knob.

4. Remove bracket screw(s). On

reassembly, test all operations of both

knobs before reinstalling screw(s).

5. To avoid spilling parts from chassis,

grasp lockset by escutcheons and

stand it on knob which will remain

in place. Support lockset so

escutcheons are parallel with work

surface, and knob to be removed

faces up.

6. Note orientation of keyway for proper

handing during reassembly. Remove

bracket and slowly pull knob off.

7. Remove cap from back of knob. If

loose, it may have remained on trim as

knob was removed. If stuck, rap end

of knob shank (

not cap!

) with plastic

or rawhide mallet to jar cap loose.

If it has become sealed in place by

paint, lacquer or brass polish, it may

be necessary to pry it loose with small

screwdriver.

8. Remove shank screws which are now

exposed. Older model has two screws

and newer model has one screw.

9. Unscrew shank from knob and remove

cylinder. If stuck, place screwdriver

shaft across slot in end of knob shank

to turn. On reassembly, be sure screw

hole(s) in knob shank align with holes

in knob before installing screws.

10. If cylinder must be dismantled, drive

out actuator retaining pin. This pin

also serves as plug retainer. LEAVE

KEYS OUT of cylinder until you are

ready to rekey it.

Caution: If you are rekeying several

of these cylinders, keep all major

components of each cylinder

together. Mixing parts may result in

end play of plug, making it necessary

to “pinch” key to remove it.

Most cylinders used in these locks

are master ring cylinders with X Class

keyways with .509" diameter plugs.

Refer to Corbin Russwin Cylinder

Manual for cylinder combinating

instructions, including all pin lengths

and key bitting specifications.

11. Clean all parts, including inside of

knob shank hole in escutcheon, and

reverse these steps for reassembly.

Use only dry powdered graphite to

lubricate cylinder. Lubricate lockset

parts as required.

Exposed Mechanism on end of chassis opposite latchbolt

1 or 2

Screws

Bracket