39

The warranty on Corbin Russwin products becomes void if the product is modified in any way, regardless of whether the modifications causes or contributes to any alleged defect. If a

Corbin Russwin product is modified it may no longer meet industry certification and quality control standards applicable to the original product and is no longer a genuine Corbin Russwin product.

Copyright © 1999-2018, ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole or in part without the express written permission of ASSA ABLOY Access

and Egress Hardware Group, Inc. is prohibited. Patent pending and/or patent www.assaabloydss.com/patents.

Service Procedures

UT5200 Parts Manual

All procedures which follow are intended for use

only with the current model lockset (Model 68)

and the current offering of functions. For obsolete

functions or models or designs, use these steps only

as a guide and tailor them to your particular lockset.

Some obsolete locksets may contain handed parts

which are not field reversible.

Changing from Knobs to Levers

This is

possible

for all functions except UT5261

but it is not practical. Major components must be

replaced and the cost can be prohibitive. In addition

to the two levers with their shanks, return springs

and spring anchors, both escutcheons must also be

changed.

Changing Hand of Lockset

Knob Version

Tools required:

Phillips screwdriver and large and

small slotted screwdriver. For UT5282 (store door)

function, Waldes ring applicator E-015 (order as

301F59-8) and second small slotted screwdriver.

To change between LH and RH, or between LHR and

RHR, turn lockset upside down. No further action is

required.

To change between regular and reverse bevel,

the components which must be switched vary by

function. For UT5210 (passage) and UT5282 (store

door), both sides operate identically, so the only

thing which distinguishes regular or reverse bevel is

which side of door has exposed screws. For UT5210,

this is purely an esthetic concern. For UT5282,

security may be a factor in the decision. If neither is

a concern for your particular application, there is no

need to reverse either of these functions.

For all other functions:

1. Remove throughbolts and chassis cover. Notice

that one escutheon is loose and the other is

fixed. Fixed escutcheon is always attached

to chassis on low side of bevel, which is side

of chassis with three vertical ribs. This will be

outside for regular bevel (RH and LH) and inside

for reverse bevel (RHR and LHR). Consequently,

fixed side will change during this procedure.

2. For all functions except UT5282 (store door),

skip to step 3.

For UT5282, remove small retainer (item #30 on

exploded view page). This can be challenging,

so be patient. With small screwdriver, rotate

retainer around spindle until its opening is in

position of easiest access. Use second small

screwdriver with first screwdriver to spread

retainer and remove it from spindle.

3.

Starting under loose escutcheon

, use small

screw driver to disengage retainer ring from

groove around chassis tube, exposing crescent

knob retainer. Remove retainer, then knob

assembly with sleeve and escutcheon. If knob

contains cylinder or button assembly, do not

allow parts to fall out of knob shank. If knob has

filler cap (optional on current model) keep it in

place. With chassis centered in your work space,

lay all parts out in order on side of chassis from

which they were removed.

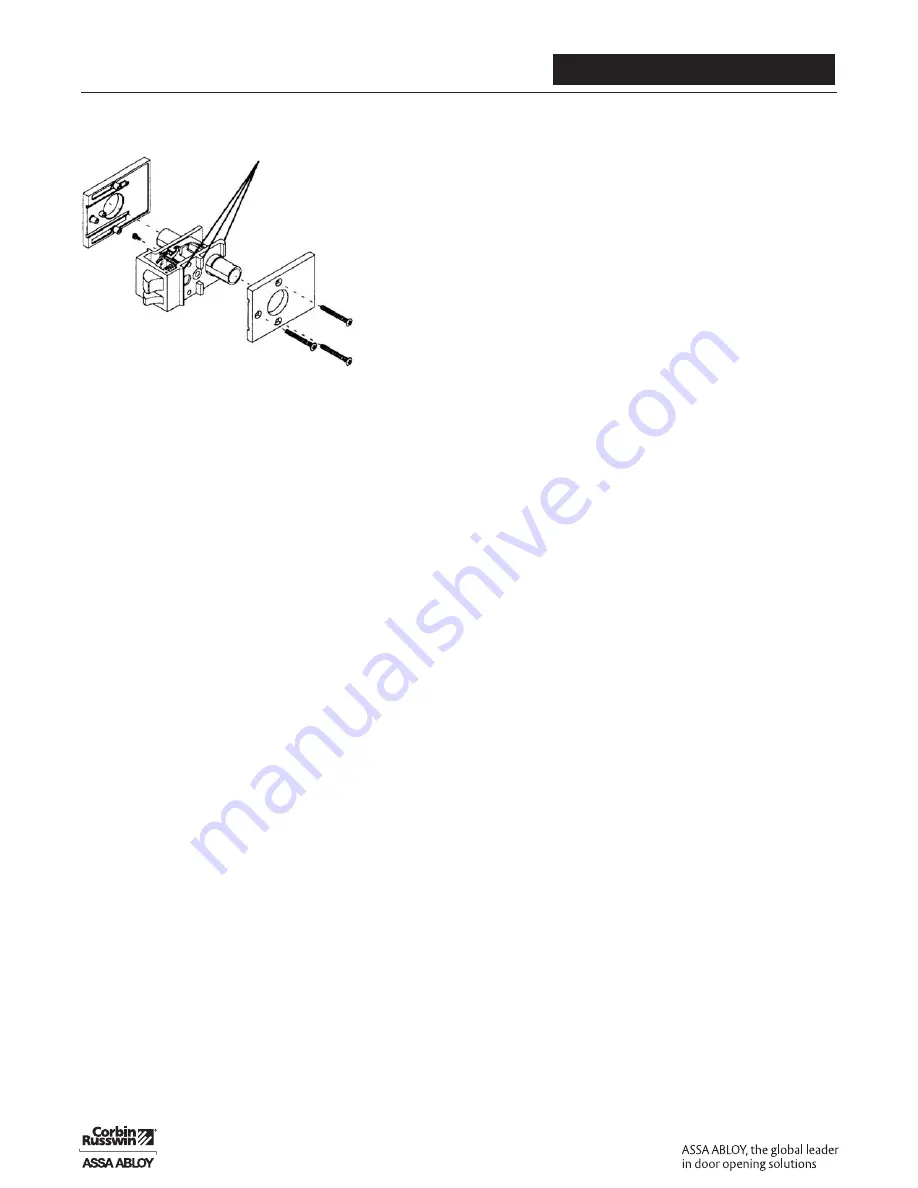

4. With all trim removed from first side, locate

phillips screw which fastens opposite escutcheon

from inside of chassis, Insert screwdriver through

access hole in wall of chassis and remove screw

and washer.

5. With second escutcheon now loose, disengage

retainer ring from groove around chassis tube,

exposing crescent knob retainer. Remove

retainer, then knob assembly with sleeve and

escutcheon. If knob contains cylinder or button

assembly, do not allow parts to fall out of knob

shank. All trim components should now be laid

out in order on proper sides of chassis.

For functions other than UT5210 (passage),

continue with step 6.

For UT5210, no further disassembly is required. Skip

to step 11.

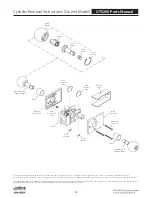

Three ribs identify side to which

fixed escutcheon is attached.

This is outside for regular bevel

(RH and LH) and inside for reverse

bevel (RHR and LHL) applications.

Mounting screw holes identify inside

escutcheon. This escutcheon is fixed

on reverse bevel and loose on regular

bevel applications.