46

EN

Assembly

Check the lock

1

Check all lock functions.

2

Check whether the latch and trip latch of the lock are pushed back from the same impact edge when

closing the door (“Profiles with thermal separation”, page 46).

3

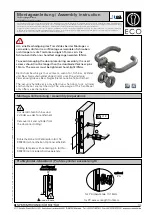

Check whether all bolts can move in and out freely without any transverse load after assembly (Fig. 7).

The lock is now completely assembled and checked for correct operation.

Fig. 7 :

Bolt is free of transverse

loads (F

Q

)

1

Strike

plate

2

Bolt

3

Faceplate

X

minimum

2 mm

F

Q

=

0

N

F

Q

=

0

N

X

X

1

2

3

Profiles with thermal separation

At tention!

Lack of finishing can lead to product malfunction:

When using profiles with thermal separation,

the components listed below must be finished with additional work.

Aluminium stop edges can lead to destruction:

Aluminium abrasion can destroy the lock or strike plate.

Finishing profile webs

When closing the door, the latch must slide over a flat surface. Some door frames, such as those with

thermal separation, may feature a profile web that interferes with the sliding surface.

ASSA ABLOY Sicher-

heitstechnik GmbH

recommends using a strike plate with a tab aperture to create a flat sliding surface

1

Cover existing profile grooves or other uneven areas.

2

Remove the webs. The profile web in the latch area must be removed down to the mounting level.

3

When closing the door, check that the latch can slide unhindered over a flat surface into the closing

position.

The profile webs are smooth and the locking function is guaranteed.

Check for full

functionality

A

Summary of Contents for MSL 23421

Page 17: ...17 Montage DE Abb 5 Sachschaden vermeiden 1 2 1 2 max 150 N ...

Page 43: ...43 Assembly EN Fig 5 Prevent material damage 1 2 1 2 max 150 N ...

Page 69: ...69 Montage FR Fig 5 Éviter les dommages matériels 1 2 1 2 max 150 N ...

Page 95: ...95 Montaggio IT Fig 5 Evitare danni materiali 1 2 1 2 max 150 N ...

Page 106: ...106 IT ...