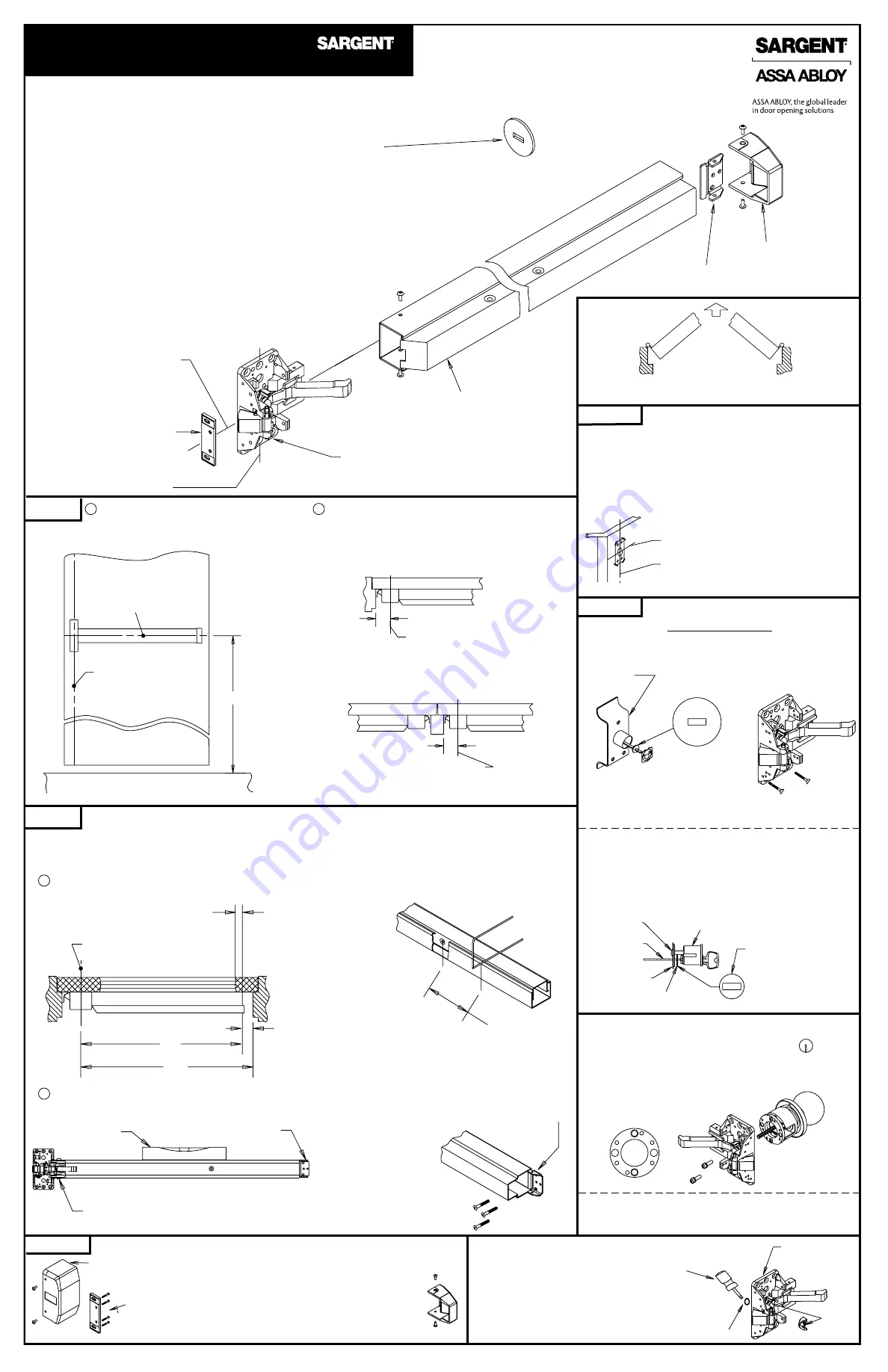

INSTRUCTIONS FOR INSTALLING

12-2828 SERIES FIRE EXIT DEVICE

K-HTB APPLICATIONS

ATTENTION! SLIDE WASHER

OVER THE CYLINDER TAIL BEFORE

BACK PLATE INSTALLATION

CAUTION!

BEFORE STARTING:

- INSTALL MULLION IF USED;

- DOOR SHOULD BE FITTED AND HUNG;

- CHECK BOX LABEL FOR SIZE OF EXIT DEVICE.

AVAILABLE STOCK LENGTHS:

LENGTH "E" - 32" DOOR, NO CUT REQUIRED.

CAN BE CUT TO FIT DOORS DOWN TO 24" WIDE.

LENGTH "F" - 36" DOOR, NO CUT REQUIRED.

CAN BE CUT TO FIT DOORS DOWN TO 30" WIDE.

LENGTH "G" - 48" DOOR, NO CUT REQUIRED.

CAN BE CUT TO FIT DOORS DOWN TO 36" WIDE.

DOOR

DOUBLE DOOR WITH 12-980 MULLION

SINGLE DOOR

DOOR

DOOR

OUT

RIGHT HAND

REVERSE BEVEL

LEFT HAND

REVERSE BEVEL

THIS EXIT DEVICE

IS NON-HANDED

IMPORTANT:

1. FOR RIM CYLINDER APPLICATIONS:

INSTALL CYLINDER TAIL WASHER TO CYLINDER

TAIL PIECE. SEE STEP THREE FOR DETAILS.

2. CLEAR AWAY ANY RAISED PROJECTIONS

TO ALLOW EXIT DEVICE TO REST

ON FLAT SURFACE OF THE DOOR.

FIRST

FINISHED FLOOR

FOR DOORS WITH STILE RAIL MUST

OVERLAP STILE BY 1/2" MIN.

FOURTH

APPLY RAIL ASSEMBLY

CAUTION:

DO NOT CUT CLOSER THAN

3 1/2" FROM THE CONNECTING

ARM PIVOT IN THE PUSH RAIL

B

A

DEPRESS ARM INTO RAIL OPENING AND SLIDE RAIL ONTO CHASSIS.

LEVEL RAIL AND FASTEN MOUNTING PLATE

FIFTH

APPLY COVERS AND STRIKE

FOR EXIT ONLY APPLICATIONS

THIRD

APPLY HARDWARE

SECOND

PREPARE DOOR

A

41"

VERTICAL REFERENCE LINE

(CL OF CHASSIS)

PLACE MOUNTING PLATE TIGHT

AGAINST RAIL AND ATTACH IT TO

THE DOOR WITH THREE #10

ROUND HEAD SCREWS

VERTICAL REFERENCE LINE

(CL OF CHASSIS)

2 1/4"

2 1/4"

ATTACH END CAP TO

MOUNTING PLATE

WITH TWO COVER

SCREWS

MOUNTING BRACKET

RAIL ASSEMBLY

ATTACH COVER TO CHASSIS WITH

FOUR #8 TRUSS HEAD MACHINE SCREWS

ATTACH STRIKE WITH TWO STRIKE

SCREWS AND ADJUST FOR PROPER

POSITION.DRILL AND TAP TWO ADDITIONAL

HOLES AND FASTEN STRIKE IN PLACE

THRUBOLT OUTSIDE

TRIM (IF USED) TO

CHASSIS

CENTER

CHASSIS

ASSEMBLY

"X"

"Y"

1 3/4" MIN.

3 1/2" MIN.

VERTICAL

REFERENCE LINE

(CL OF CHASSIS)

HORIZONTAL

REFERENCE LINE

(CL OF CHASSIS AND

RAIL ASSEMBLY)

HORIZONTAL

REFERENCE LINE

(CL OF CHASSIS AND

RAIL ASSEMBLY)

VERTICAL REFERENCE LINE

(CL OF CHASSIS)

VERTICAL

REFERENCE LINE

(CL OF CHASSIS)

HORIZONTAL REFERENCE LINE

(CL OF CHASSIS AND RAIL ASSEMBLY)

VERTICAL REFERENCE LINE

(CL OF CHASSIS)

WHEN CYLINDER IS USED -

IT MUST BE POSITIONED IN

THE MIDDLE OF TRIM, AS

ILLUSTRATED

LEVEL

ATTACH RAIL ASSEMBLY TO THE CHASSIS

WITH TWO #8 TRUSS HEAD MACHINE SCREWS.

MOUNTING PLATE

END CAP

649 STRIKE SHOWN

HOLD DOWN PUSH RAIL,

CUT OFF AND DEBURR.

APPLY TEMPLATE ON THE DOOR ALONG REFERENCE

LINES AND TAPE IT WITH SUPPLIED TAPE.

IF DOOR ALREADY HAS ANSI DOOR PREP

(161 CUT-OUT), OR HAS 2 1/8" DIA HOLE AT 2 3/4"

BACKSET,POSITION TEMPLATE OVER EXISTING

HOLE & MARK FOR 4 CHASSIS MOUNTING HOLES.

MARK VERTICAL AND HORIZONTAL

REFERENCE LINES ON THE DOOR

DETERMINE CUT OFF DIMENSION "X" BY SUBTRACTING 1 3/4" FROM DIMENSION "Y".

MARK CUT OFF POINT ON MOUNTING RAIL.

• CHECK BOX LABEL. IF CUTTING IS NOT REQUIRED PROCEED TO STEP "B".

• IF CUTTING IS REQUIRED, CONTINUE WITH STEP "A".

B IDENTIFY TYPE OF INSTALLATION TO

DETERMINE LOCATION OF VERTICAL CL

RETAINING RING

SCREWDRIVER

CENTER CASE

CHASSIS

ASSEMBLY

CAM

USING RETAINING RING

PLIERS (NOT SHOWN) OR

SCREWDRIVER TO REMOVE

RETAINING RING FROM THE

CAM AND CAM FROM THE

CENTER CHASSIS ASSEMBLY

FOR FLUSH MOUNTING.

ATTACH CHASSIS

WITH FOUR #10

WOOD OR

MACHINE SCREWS

KNOB TRIM APPLICATIONS

TRIM IS NON HANDED.

1. SCREW THE ROSE DOWN ALL THE WAY.

2. WITH KEYHOLE FACING DOWN, POSITION TRIM

IN CROSS BORE HOLE, AND ATTACH TO CHASSIS

WITH (2) #10-32 FILLISTER HD. MACHINE SCREWS.

**FOR LEVER TRIM APPLICATIONS, SEE INSTRUCTION

SHEET A7274 PACKED W/LEVER TRIM.

ATTENTION:

USE STANDARD SHIMS FOR

CENTER CHASSIS MOUNTING

FOR RIM CYLINDER ONLY APPLICATION

RIM CYLINDER

ASSEMBLY

MACHINE

SCREW

CYLINDER

TAIL PIECE

CYLINDER

BACK PLATE

CYLINDER TAIL WASHER

ATTENTION:

SLIDE CYLINDER TAIL

WASHER OVER THE

CYLINDER TAIL PIECE

BEFORE ATTACHING

CYLINDER BACK PLATE

TO THE DOOR

SPOT AND DRILL HOLES.

CYLINDER

TAIL WASHER

VR

RIM

AL

RM

A6368 N

Copyright © 2009, 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without the express written permission of Sargent Manufa

cturing Company is prohibited.

Patent pending and/or patent

www.assaabloydss.com/patents