20

7300 Series

Installation Instructions

Multi-Point Lock

A8270A 02/20

Copyright © 2017, 2019, 2020 SARGENT Manufacturing Company. All rights reserved. Reproduction in whole or in

part without the express written permission of SARGENT Manufacturing Company is prohibited.

1-800-727-5477 • www.sargentlock.com

5 Addendum

(cont.)

i

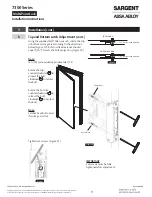

Secure Top Latch

• Install four (4) 10-24 oval head

screws on the face of the door.

(Figure 42)

• Install six (6) 1/4-20 flat

head screws in the top edge of the

door. (Figure 43)

Note:

Do not fully tighten until all

screws are installed.

j

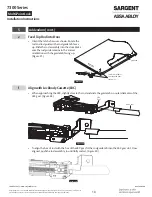

Tighten Set Screw

Using the supplied 1/8" Allen wrench, tighten the set screw to secure the rod to the LBC.

(Figure 44)

IMPORTANT

Latches will not retract if the set screw is not tightened.

Figure 44

Figure 42

Figure 43