An ASSA ABLOY Group brand

80-9086-0050-010 (10-12)

5

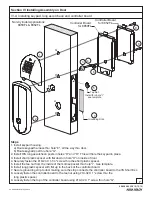

Section II Prepare the Door

B) Mark centerline for lever position and door template

1. Draw a horizontal centerline for the lock lever/spindle on both sides of door at desired height

above finished floor line. Standard height for horizontal centerline is 39-15/16˝ above finished

floor.

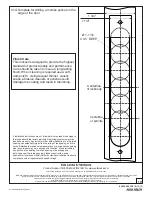

2. Compare the lock function number being installed with hole chart (See Template) to determine

the holes to be marked.

3. Position the installation template on the door so that the horizontal centerline lines up with the

marked horizontal line on the door, and the desired edge of the template lines up with the edge of

the door.

4. Mark the holes to be drilled using a scribe, center punch, or nail on the inside and outside of door.

To avoid shifting of the template, it may be taped to the door during this step.

C) Drill holes in door

1. Bore marked trim holes (step B4). To avoid splintering wood, bore thru holes from both sides of

door.

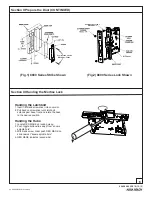

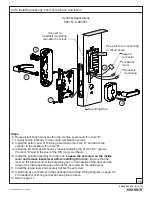

D) Mark frame for strike mortise cavities

1. Mark the vertical position of strike on jamb using the reference centerline on installation template.

Mark location of strike lip.(FIRST DETERMINE IF SILENCERS ARE TO BE USED) To locate

horizontal centerline of strike, take half the door thickness PLUS the thickness of silencer (if used).

Use this dimension to locate the strike centerline from the doorstop. (See Fig. 1, page 6)

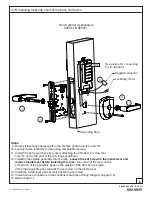

E) Drill Mortise Cavities in door and frame

1. Align mortise pocket template on edge of door using the spindle height mark.

2. Mark door edge for lock body attaching screws and mortise pocket.

3. Mortise door edge for lock body 4½˝ deep. See page 14 for Template.

4. Drill pilot holes for attaching screws.

5. Slide lock body into cavity and attach using the combination attaching screw. Install armor front

and use as template. Mark outline.

6. Mortise door edge for lock front (7/32˝) deep.

7. Mortise jamb for strike (3/32˝ deep). Be sure to mortise 1˝ (25mm) deep to accommodate lock

bolts or strike

F) Install Strike

1. Attach strike to jamb using two #12 combination attaching screws. (See Fig. 1, page 6).

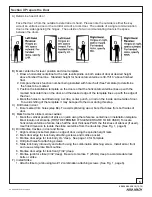

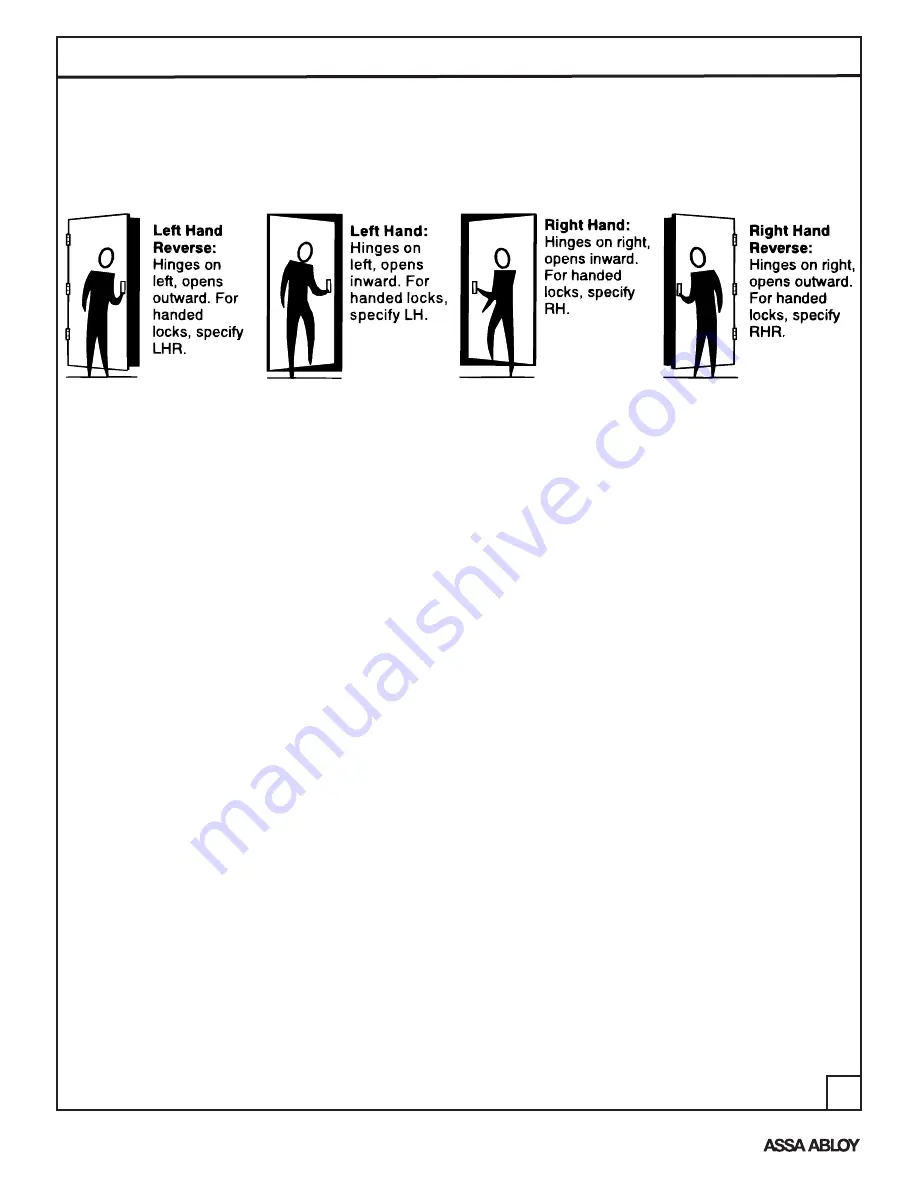

A) Determine hand of door

Face the door a from the outside to determine its hand. Please note the outside is either the key

side of an entrance door or the corridor side of a room door. The outside of a single communication

door is the side opposing the hinges. The outside of a twin communicating doors is the space

between the doors.