-

+BATTERY-

-

15

step 5

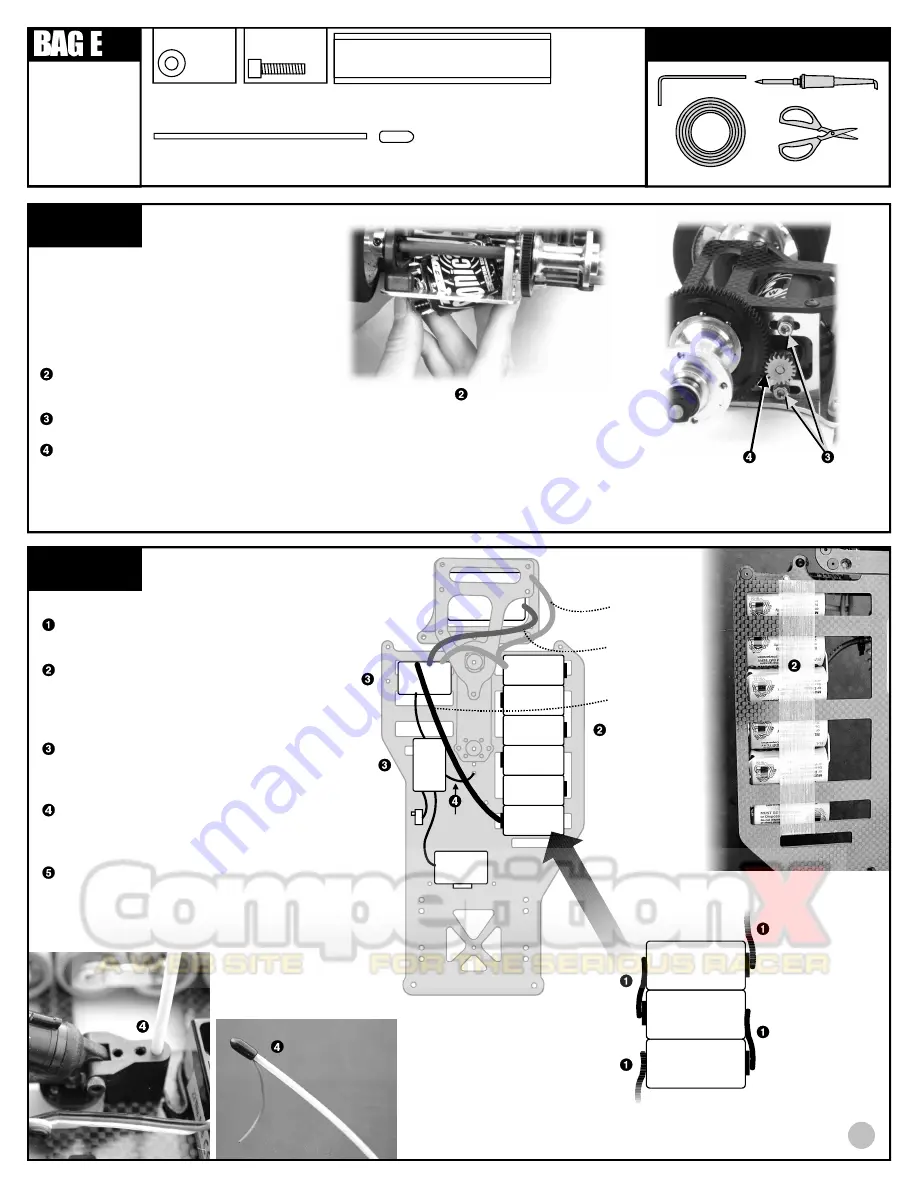

PINION GEAR INSTALLATION

Slide the pinion gear onto the shaft so that the

gear is 1/16" away from the motor can. Tighten

the set screw to hold it in place. Teeth side

should be farthest from can.

MOTOR INSTALLATION

Insert the motor into the rear pod assembly as

shown, the pinion gear coming through the

right side motor bulkhead.

Tighten the motor to the bulkhead with two

#6515 screws and two #7337 gold washers.

Set the gear mesh so that there is very little

play between the spur and pinion gear.

Note:

If the gear mesh is too tight, you can lose

significant power.

REMOVE THESE

PARTS FOR:

8018: steps 5-6

TOOLS USED

7337, qty 2

washer

gold, steel

1:1

MOTOR AND PINION GEAR ARE NOT INCLUDED IN KIT

6515, qty 2

3mm x 10mm

gold

1:1

step 6

STEERING

SERVO

-

+BATTERY-

-

+BATTERY-

-

+BATTERY-

SPEED

CONTROL

MOTOR

+

+

__

ELECTRICAL INSTALLATION

Solder your single cell batteries together

with battery braid or battery bars. Solder

plus (+) to minus (-).

Hold the batteries to the chassis with

strapping tape. Wrap the tape over the

batteries, through the chassis slot,

underneath the chassis, and up again

through another slot, several times.

Cut the #6726 servo tape to fit the

bottom of the speed control and receiver.

Peel the backing from the servo tape and

place them where shown in the drawing.

Insert the #3716 antenna into the

antenna mount. Slide your receiver

antenna wire through the antenna and

secure the wire with the antenna cap.

Now connect the electronic speed control

and steering servo to your receiver

according to your radio or ESC

instructions,

then connect the motor to

the ESC and battery.

ELECTRICAL ITEMS ARE NOT INCLUDED IN KIT

3716, qty 1

antenna

3716, qty 1

antenna cap

strapping tape

R

E

C

E

IV

E

R

6726, qty 1

servo tape strip

antenna

wire

1

RED WIRE

BLUE WIRE

BLACK WIRE

3/32"

TOP VIEW

BOTTOM VIEW