15

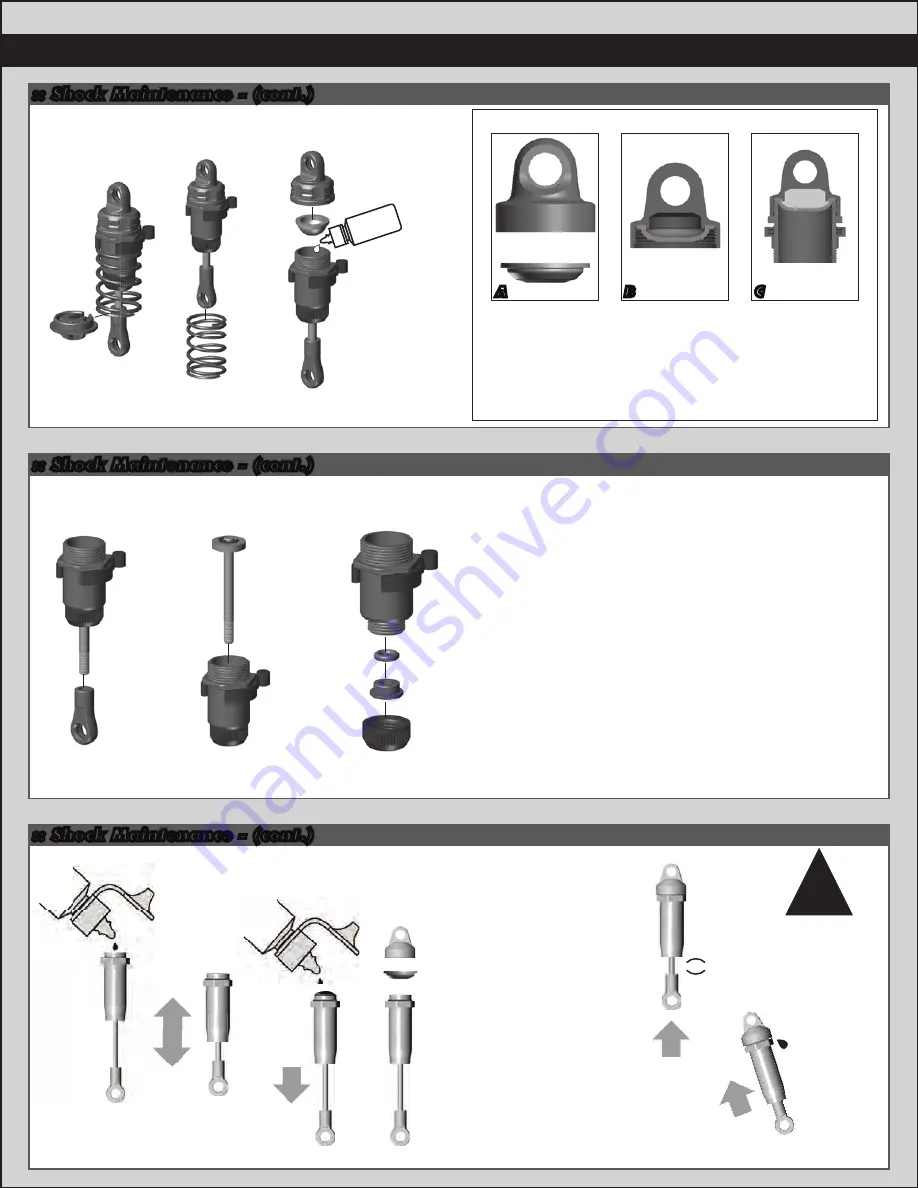

:: Shock Maintenance - (cont.)

:: Shock Maintenance - (cont.)

:: Shock Maintenance - (cont.)

Shock Maintenance:

If you need to only refill your shocks with oil, follow the steps

above only then move to the shock bleeding steps.

If your shocks leak from the bottom shock cap, follow all

shock maintenance sections.

Replace the inner O-Ring in the bottom cap, then begin the

shock oil filling and bleeding process.

Step 9-10

Stock Shock

Fluid Setting:

Front: 35wt

Rear: 35wt

Step 6-8

Slow

Slow

Check for

pressure

Step 5

Step 3-4

Step 1-2

Shock Bleeding Steps:

1.

Pull shock shaft down.

2.

Fill shock body 3/4 full with silicone

shock fluid.

3.

Slowly move the shock shaft up and

down to remove air from under the

piston.

4.

Wait for bubbles to come to surface.

5.

Fill shock body to top with silicone

shock fluid.

6.

Place a drop of oil in the cap and on

cap threads.

7.

Install cap and tighten completely.

8.

Unscrew the cap 3/4 turns and tilt

the shock at a slight angle.

9.

Slowly compress shaft all the way to

bleed excess silicone shock fluid and

air. You should see bubbles coming

out from under the cap. (use rag

around shock to catch excess fluid).

10. With the shaft compressed, tighten

the cap and re-check for pressure at

the top of the stroke. If there is still

pressure, repeat steps 3-9.

Some residual

shock fluid may

appear from your

first few runs

around the shock

cap as a result of

bleeding.

!

Bladder Installation

As you install the shock cap with the bladder, it will force

out any extra fluid. If you install the cap with the shaft

fully extended, you are running FULL REBOUND.This

means the shaft will fully rebound when compressed.

To run less rebound, unthread the cap 1-2 turns and

compress the shaft to the desired position and

re-tighten the cap with the shaft compressed.

Start with no rebound.

A

B

C

35wt

Shock fluid

Summary of Contents for Qualifier Series

Page 1: ...12 12 ...

Page 10: ...10 Spur Gear Access Spur Gear Access cont ...

Page 29: ...29 Notes ...