17

:: ESC Manual

#29138

XP SC500-BL

Brushless ESC

Introduction

Congratulations on your X

P

Brushless Electronic Speed Control (ESC)

purchase. The latest electronics technology along with the design and

engineering experience that is responsible for multiple World Championship

titles has been incorporated into its design.

Your X

P Brushless ESC is water-resistant for maximum durabilit

y

. Its light

and compact design allows for easy installation in most 1/10 vehicles.

Simple calibration and a wide variety of tuning options make this ESC perfect

for both casual enthusiast and racers. When paired with a Reedy Brushless

Motors, you create a potent combination of power and efficiency that brings

performance to a new level. More power and less maintenance elevate the

fun factor by increasing top speeds and reducing down time.

Please read the following before installing and operating

your new ESC.

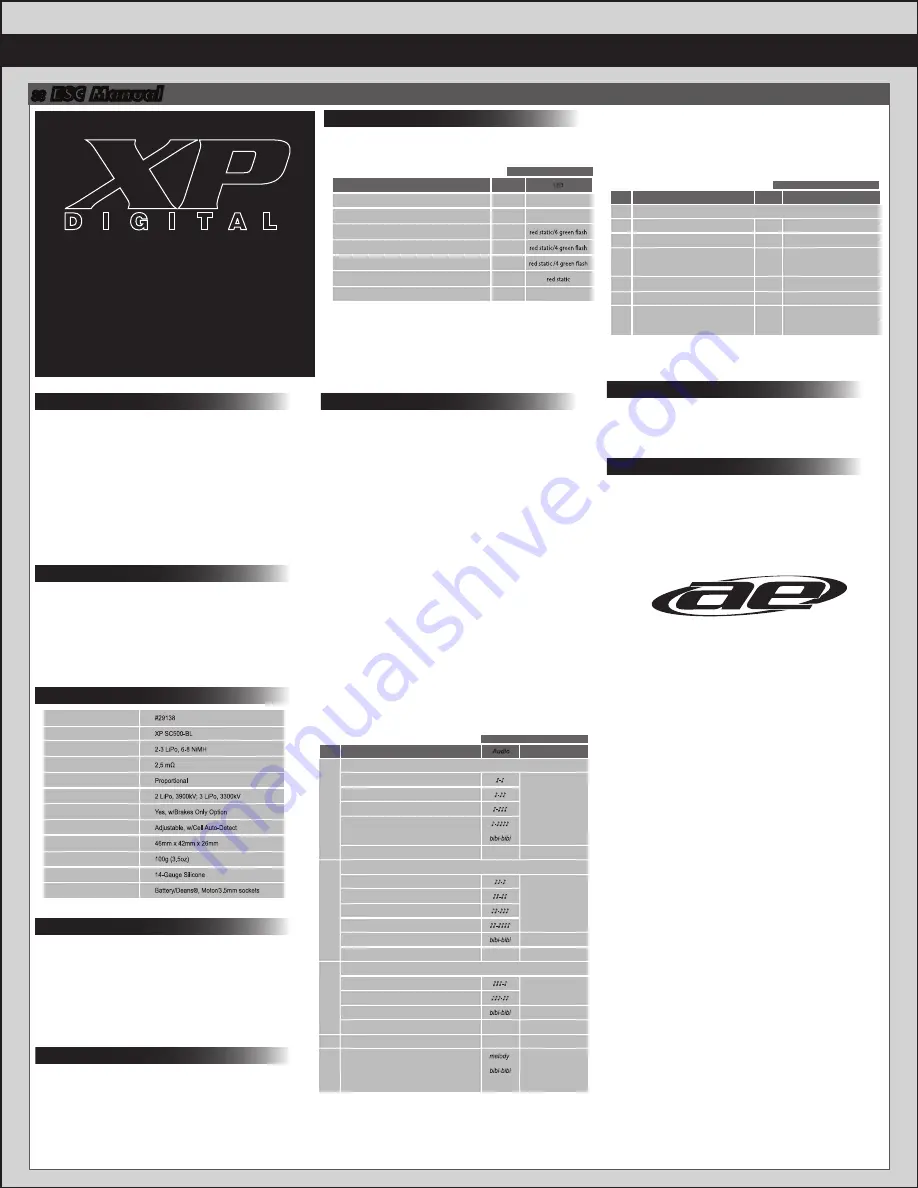

Specifications

Features

•

A

djustable LiPo Low-V

oltage Cutoff

• LiPo Cell Count

Auto Detect

• Reversible With Reverse Lockout

• Fully Proportional Brakes

•

A

djustable Drag Brakes

•

Adjustable

Throttle Profile

• Hard Case with

A

luminum Heat Sink

•

Water Resistant

• Heavy Duty Silicone Wire

s

• Deans® Ultra Plug® Connector

• 3.5mm Motor Connector

s

• Pre-Wired For Optional Cooling Fan

Description

Cells

On Resistanc

e

Brakes

Motor Limit

Reversible

Low V

oltage Cutoff

Dimensions

Weight

Power Wires

Connector Type

Installation

• Mount your ESC securely using double-sided tape.

• Install your ESC in a position that allows easy access to all connectors.

• Plug the ESC

’s

receiver wire into the receiver (refer to radio

manufacturer’s manual).

•

T

o prevent radio interference, arrange ESC wiring so that it is not in close

proximity to the receiver antenna wire.

• Connect the three motor leads exiting the ESC to the three leads exiting

your motor

. If the motor runs backwards when giving it forward throttle,

reverse any two motor leads.

The motor will now run the desired direction.

•

A

lways power ON your transmitter before the ESC and power OFF the

ESC before the transmitter.

Safety Precautions

This product is a sophisticated hobby product and not a toy

. It must be

operated with caution and common sense and requires some basic

mechanical ability. Failure to operate this product in a safe and responsible

manner could result in injury or damage to the product or property. This

product is not intended to be used by children without direct adult

supervision. It is essential to read and follow all instructions and warnings

found in this manual prior to installation, set up, and use, in order for the

product to operate properly and to avoid damage or injury

.

Your new ESC must be calibrated before use. Before calibration, be sure to

set your radio’

s throttle and brake EP

As to 100% and your throttle trim to

neutral. Then follow the steps outlined below.

Throttle/Brake Calibration

Procedure

Power ON transmitter

Throttle trigger pos tion to maximum throttle (hold)

Power ON ESC

Throttle trigger pos tion to neutral

Throttle trigger pos tion to maximum brake

Throttle trigger pos tion to neutral

Power OFF ESC, Power OFF transmitter

Signal From ESC

Audio

bibibibibibi

bibi-bibi

bibi-bibi

Once the calibration procedure is complete, turn on your transmitte

r, then

your ESC, and begin operating your vehicle. Note: If you choose to make

settings adjustments at this time, you can do so immediately after step #6

of the throttle calibration procedure.

Y

our ESC comes with pre-programmed default settings. But you can also

change the settings based on the type of vehicle and battery used as well

as personal performance preferences based on the track you are driving on

and your driving style.

Drag Brake

- Drag brake is the amount of braking achieved when the throttle

is returned to neutral. A

setting of 0% means the vehicle will free wheel to a

stop while higher settings will stop the car faster

. Please note that regardless

of the drag brake setting, you will still be able to use the brake trigger to

manually slow the car.

Throttle Profile

–

This setting adjusts the power delivery of your ESC/motor

combination. The Ve

ry Soft setting can be used on loose or bumpy track to

reduce wheel spin while the Maximum setting works well when high traction is

available. Four settings provide options for any track condition.

Run Mode

- This gives the option of using reverse or eliminating it completely

(for competition). With reverse activated, you will still have fully proportional

braking.

T

o make settings adjustments, you must first follow the calibration

procedure. Y

ou will encounter a 5-second delay before entering step #1 of the

settings adjustment mode. All changes will be made using your transmitter’s

throttle trigger.

Note: Once you enter the settings adjustment mode, the ESC

will scroll through all options. If you fail to choose a setting, the ESC will keep

the previously saved setting.

For example, if you want to change the throttle profile from Soft to Standard,

enter the settings mode. Y

ou will encounter the Drag Brake mode first at

which time you can let the ESC scroll through the choices (the previously

saved setting will be kept) until you reach the Throttle Profile choices.

You

must make the selection by pulling the throttle trigger to maximum after the

ESC scrolls to the desired setting (in this case Standard) indicated by the

appropriate audible tones. Once this setting (or any setting for that matter) is

chosen, you can skip to Step #4 if no other changes are desired.

Programmable Settings

Procedure

Drag Brakes

0%

2.5% (default)

5%

10%

Throttle trigger position to maximum to select value

Throttle position to neutral

Throttle Profile

Very Soft

Soft (default)

Standard

Maximum

Throttle trigger position to maximum to select value

Throttle position to neutral

Run Mode

Reverse Off (Forward Only)

2-stage Reverse (default)

Throttle trigger position to maximum to select value

Throttle position to neutral

Power OFF ESC and transmitte

r

Power ON transmitter and ESC

Step #

1

2

3

4

5

LED

red static/green flashes

red static/4 green flash

red static

red static/green flashes

red static/4 green flash

red static

red static/green flashes

red static/4 green flash

3 green flash, 2 red

flash/green static

or red static

Signal From ESC

Warranty

Your X

P

Electronic Speed Control is warranted to the original purchaser for

30 days from the date of purchase, verified by the sales receipt, against

defects in material and workmanship. Product that has been mishandled,

abused, used incorrectly, used for an application other than intended, or

damaged by the user are not covered under warrant

y.

Associated Electrics Inc. is not liable for any loss or damage, whether direct

or indirect, incidental or consequential, or from any special situation, arising

from the use, misuse, or abuse of this product.

Vehicle Operation

To

operate the vehicle, pull back on the throttle trigger to move forward and

push forward on the throttle trigger to engage brakes.

T

o engage reverse,

push forward on the throttle trigger to maximum brakes. Hold the trigger in this

position for at least .5 seconds before returning the throttle trigger to neutral.

Now push the throttle trigger forward to reverse the vehicle.

Battery Management System

-

A

choice of either LiPo mode or NiMH mode

adjusts the low voltage cutof

f point.

This is critically important when using LiPo

batteries that should not, for performance and safety reasons, be discharged

below 3.0V per cell. In LiPo mode, the ESC detects whether you are using 2

or 3 cells and adjusts the cutof

f accordingly.

The ESC can be toggled between LiPo and NiMH by following the steps

outlined below.

IMPO

RT

ANT! When the transmitter and ESC are turned on, the color of the

ESC LED at neutral indicates which mode the ESC is in. When the LED is

green, the ESC is in LiPo mode. When the LED is red, the ESC is in NiMH

mode.

Associated Electrics, Inc

26021 Commercentre Dr.

Lake Forest, CA 92630 USA

www.teamassociated.com

www.rc10.com

call: (949) 544-7500

fax: (949) 544-7501

Procedure

Battery Management System

Power ON Transmitter

Trigger position to maximum brake (hold)

Power On ESC

Throttle position to neutral

Power OFF ESC, then transmitter

Power ON transmitter, then ESC

Step #

1

2

3

4

5

6

LED

2 green lash/ green static (LiPo Mode)

or red static (N MH Mode)

3 green flash, 2 red flash,

green static or red static

Signal From ESC

Audio

bi-bi

melody

bibi-bibi

Summary of Contents for Qualifier Series

Page 1: ...12 12 ...

Page 10: ...10 Spur Gear Access Spur Gear Access cont ...

Page 29: ...29 Notes ...