page 16

diff outdrive hub, which could damage parts or reduce the

performance of the diff. Slide the diff spring into the left diff

outdrive hub. It should slide in or go in with very light pressure

until the spring reaches the bottom of the outdrive hub cavity.

(4) Next align the T-nut with the slots in the outdrive hub and

push it in. Make sure the steel insert side goes in first. This

will place the T-nut "ears" on the outside away from the diff

spring. Slide the T-nut all the way down against the spring.

(5) (Fig. 48) The ears on the T-nut should be approxi-

mately 3/32" or a little less than .100" from the bottom of the

slot. Take your X-acto knife and trim off any of the plastic T-

nut that extends outside both sides of the slot in the outdrive

hub. The diff outdrive hub will not fit through the ball bearing

in the case if we do not take care of this now.

WARNING!! Be

careful here so that you do not cut yourself, since you

will be cutting towards your thumb.

Fig. 46

Fig. 47

Fig. 48

Fig. 49

❏

Fig. 50

(1)In bag A you will also find a little bag

containing the six smaller #6574 5/64" precision thrust balls.

In another little bag you will find the #6575 2-56 diff thrust bolt

and the two #6573 (special hardened steel washers) diff

thrust washers.

WARNING! NEVER replace your thrust

balls with any other balls except our #6574 thrust balls

The tolerances we use are tighter than most other

companys'. Due to these tight tolerances and careful

packaging of matched balls, when replacing lost or worn

5/64" thrust balls, you MUST replace ALL 5/64" balls at

the same time with new balls from the same package.

This means you cannot even mix balls from two separate

#6574 packages.

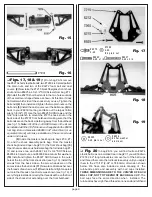

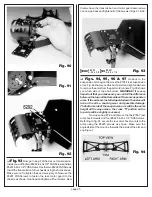

(2) Slip one of the #6573 diff thrust washers onto the

#6575 diff thrust bolt as shown.

Racer's Tip: Carefully look

at the center hole of the first thrust washer; you will be

see that each side is beveled. One side is beveled more

than the other; This side is installed towards the head of

the thrust bolt. This will help to insure that the thrust

assembly will work as smoothly as possible. (3) Go back

to the Assoc. main bag and locate the tube of #6588 black

grease. (4) Open the tube and place a small amount on the

washer. Use just enough grease to hold the six balls in place

on the washer.

WARNING! Do Not use the #6591

Assoc.

diff lube on the six #6574 5/64" diff thrust balls. (5) Now

carefully place the six #6574 balls in the grease around the

washer. (6) Slide the second washer onto the bolt until it

contacts the balls.

WARNING!! Make sure that you have

exactly six thrust balls installed between the washers.

More than six will cause the diff to back off and less than

six can cause the thrust washers to crack.

Fig. 50

❏

Fig. 51

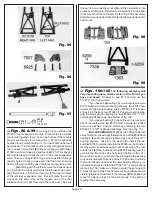

(1) Remove the #7667 right diff outdrive hub

and one of the #7666 diff drive rings from bag A. Go back to

bag B and take out the second 5/32" x 5/16" #6589 unflanged

ball bearing or #6597 5/32" x 5/16" unflanged bushing (re-

member these parts are determined by which kit you pur-

chased). Now check to make sure that there are no burrs or

residue on the inside or outside of the right diff outdrive hub

which could damage parts or reduce the performance of the

diff. (2) Install the #6589 bearing or #6597 bushing into the

cavity in the center of the right diff hub. It should just push in

with your finger. Never drive or force the bearing or

bushing into the hub cavity! (3) Now place the #7666 diff

drive ring onto the right diff hub.

Racer’s Tip: The Team

Drivers always check the diff drive rings for the side that

is more rounded on the edge and place this side against

the hub which will give you the best diff action possible.

Do not try to pin the drive ring to the hub. This hub and

ring system are designed to lock the drive ring without

pinning. Please leave it AS IS.