page 17

Fig. 51

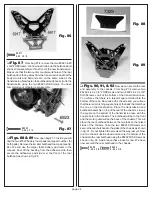

#6 589

5 /3 2 x 5/1 6

u nfla ng ed b ea rin g

❏

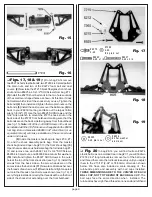

Fig. 52

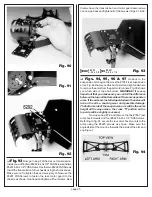

Go back to your #6950 tool bag and remove

the 5/64" Allen wrench. Slide the long end of the Allen wrench

into the head of the #6575 diff thrust bolt. We will be inserting

the bolt, washers, and thrust balls into the center of the #7667

right diff outdrive hub, as shown.

Note: Associated’s #6959

5/64" Allen wrench will work well here.

Fig. 52

❏

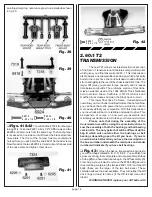

Fig. 53

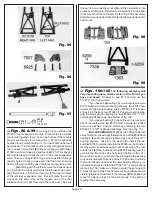

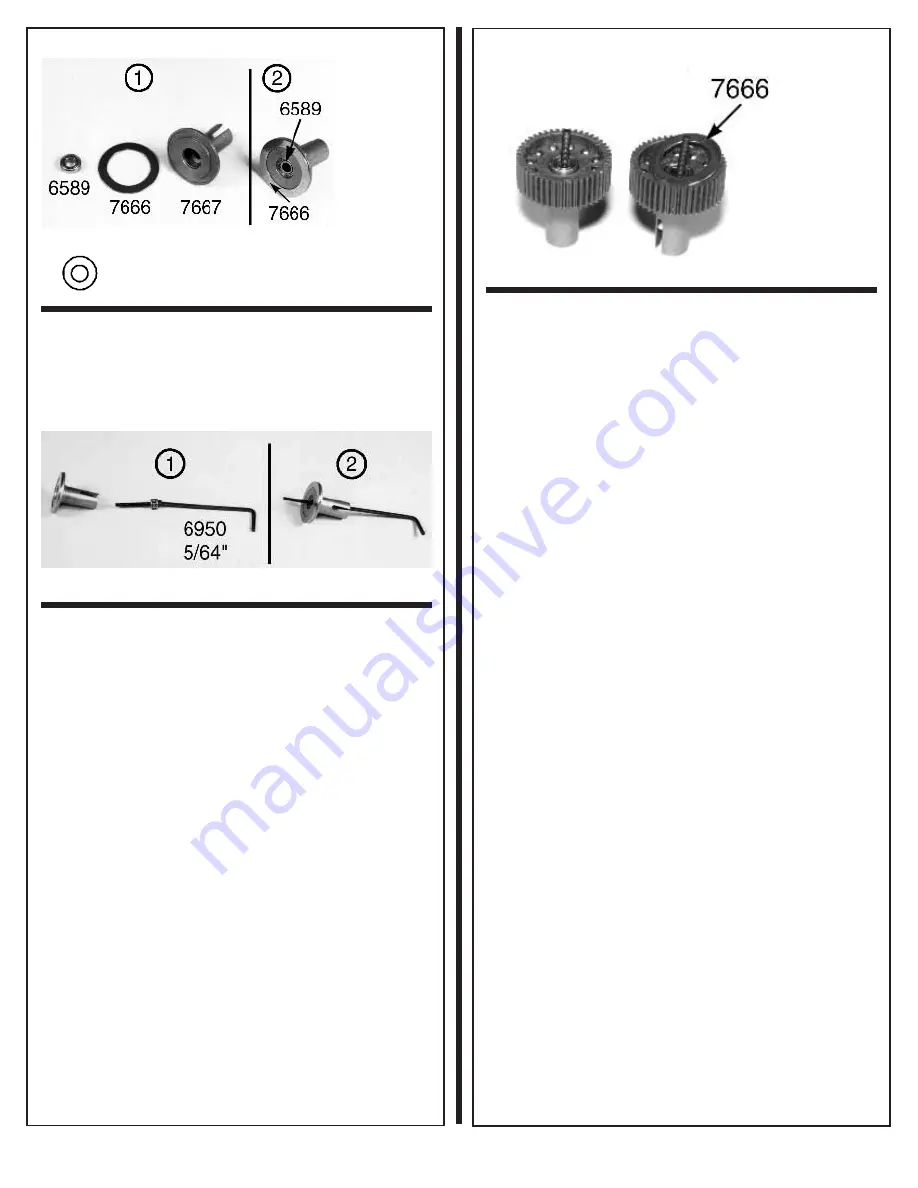

With the Allen wrench still in the head of the

diff bolt, turn the hub assembly upright so that the wrench is

on the bottom. Make sure that the #7666 diff drive ring is still

on and centered. Now pick up the #7664 diff drive gear with

the balls and bearing installed and slip it over the #6575 diff

thrust bolt onto the drive ring and hub. We want to center it on

the diff drive ring on the right diff hub.

Now go back to bag A and take out the second #7666

diff drive ring. We are going to install this second drive ring on

the top side of the diff gear over the diff balls and center it as

best as you can. Note: In the photo for fig. 53 we have

removed the Allen wrench so that you can see the diff

gear before the #7666 drive ring is installed and as it is

being installed. Remember, if you are doing the racers

setup the rounded side will be up.

WARNING! If you remove

the gear at any time before you completely assemble the

diff halves always double check to make sure you do not

have both drive rings on the same side. This can be easy

to do because one drive ring may stick to the diff gear

and the other could be stuck to the diff outdrive hub.

Fig. 53

❏

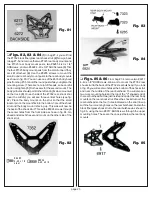

Figs. 54 & 55

(1) With the Allen wrench still in the

diff bolt, turn the right hub so that the end of the bolt is facing

up.

WARNING!!: Make sure you securely hold the Allen

wrench in the head of the diff thrust bolt. This will

prevent the bolt, washers and possibly the diff thrust

balls from falling out during assembly and possibly

getting lost. (2)Now we are going to install the #7668 left diff

drive hub assembly over the #6575 diff bolt until it seats on

the #7666 diff drive ring (as shown in fig. 54). When picking

up your left diff hub place your finger over the slotted end of

the hub so that the T-nut and spring cannot fall out. Make sure

that the outdrive hub centers on the top diff drive ring when

it fits into the center of the diff gear. (3) While holding the

upper diff hub, tighten the diff bolt using the Allen wrench.

Please make sure the hubs and diff drive rings stay centered.

(4) Once you have lightly snugged the two halves together

you can turn the diff assembly sideways, as shown, to make

the final adjustment easier (see fig. 55). Hold the left hub and

tighten the screw until it stops. This will fully compress the diff

spring under the T-nut. DO NOT OVERTIGHTEN. Correct

adjustment is tightening the diff bolt and spring until the stop,

then backing the bolt off 1/8 of a turn.

When the adjustment is finished the diff should be

tight but the operation of the diff should feel smooth when

turning the hubs in opposite directions. Remember this is not

a free spinning component. We are looking for the ball rolling

motion to feel smooth not rough.

Note: After you have run

the car once, you will need to recheck the diff adjust-

ment. The first run makes sure that all the parts seat

correctly. After you have rechecked the diff adjustment

it should only be necessary to check the diff adjustment

occasionally.

ADJUSTING THE DIFF: As you are tightening the

diff bolt, you will notice the ears on the T-nut moving closer

to the bottom of the slot in the left diff outdrive hub. This

causes the diff spring (under the T-nut) to compress. The

spring and diff bolt should stop about the same time as the

T-nut ears reach the bottom of the slot. If it is only off by a

small amount, there is no problem. Bottoming out the spring

and bolt is very important. The tension of the spring can only

be consistent if you start from the same point each time. A

fully compressed spring is your starting point. This way, when

you back off the bolt 1/8 of a turn you will always have the

same spring tension, so your diff will be consistent. We again