page 35

Fig. 135

❏

Fig. 136

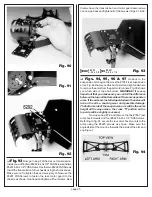

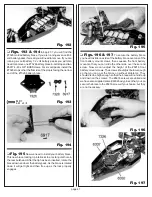

(1) Take one of the front shocks and slide

the shock cap over the upper shock bushing on the front

shock strut. (2) From bag #7-10 remove two #6222 4-40/5-

40 black self thread nylon locknuts. (3) Thread the #6222 nut

onto the shock mounting screw to hold the shock cap in

place. Only tighten the nuts just enough to make contact with

the shock bushings, but not enough to cause binding.

(4) Go back to bag #7-10 and take out the two #7874

4-40 x 7/16" SHCScrews. (5) Now line up the pivot ball on the

bottom of the shock with the outside shock mounting hole on

the front suspension arm. Make sure the pivot ball is on the

front side of the front arm mount. (6) Fasten the shock pivot

to the arm with the #7874 SHCScrew. (7) Now do the same

for the other front shock. Be careful not to overtighten the

screws which can cause shock binding. Most drivers prefer

to install their shocks with the spring clamp adjusting screws

on the outside, facing forward, to make adjustment easier.

# 78 74

4 -4 0 x 7 /1 6

#62 22

4-4 0/5-40

ny lo n lock nu t

Fig. 136

❏

Fig. 137

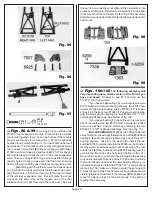

This photo shows all four shocks installed

onto the truck. We have now completed the chassis assem-

bly.

Fig. 137

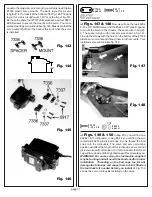

STEERING SERVO SECTION

We are now ready to install the steering servo. If you

have not purchased a radio yet, we recommend that you stay

with a name brand company like Airtronics, Futaba, or

JRpropo. However, it may be possible to use many other

radios, including some stick models. This is something we

recommend you determine before you purchase the radio

system or you will need a written guarantee from the dealer

that they will take it back if it will not work or fit correctly.

Because of the additional loads on the steering

system (wider and heavier tires) we recommend using only

medium sized servos with a minimum of 42 oz. in. of torque

for the steering servo. Most quality radio systems come with

medium sized servos that have torque ratings in the low 40’s,

but check the specifications just to be sure.

Racers Tip: If

you want your truck to be able to perform a little better and

more consistently, most racers look for a ball bearing servo.

When used for their steering servo, they prefer a servo that

has at least 55 oz. in. of torque.

The speed of the servo will depend upon your

preference. Standard servos have speeds normally between

.22 to .24 sec. for 60° of travel. High speed servos have