page 41

Fig. 162

❏

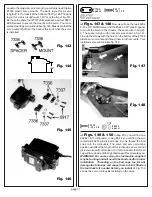

Figs. 163, 164 & 165

(1) From the same bag

remove the two #8850 black aluminum throttle resistor brack-

ets, the #6711 throttle resistor, two #6932 4-40 x 5/16" socket

head cap screws, and two #6936 #4 aluminum flat washers.

There is a left and a right side to the two resistor mount

brackets.(2)We will start with the left bracket as shown in fig.

163. Use one of the #6932 screws and #6936 washers to

secure the left bracket to the left side mount. Make sure the

bracket bends away from the servo. We want the top of the

bracket to also be parallel with the ground. (3) Look closely

at the throttle resistor. You will see that there is a slot running

through the center of the resistor. This is how it will be

mounted. Now we can take the #6711 throttle resistor and

slide it onto the left bracket (see fig. 165). Make sure the

solder tabs on the resistor are facing away from the servo and

that the silver bands are facing up. (5) Next we can pick up

the right side bracket and slide it into the slot from the right

side. (6) The small slot on the lower portion of the bracket

needs to be lined up with the mounting hole on the right servo

mount. (7) Use the remaining #6932 screw and #6936

washer to secure the bracket to the right mount.

Note: The

brackets have vertical slots for the mounting screws. This will

allow us to adjust the height of the resistor to make sure we

have good electricl contact between the resistor and the

wiper arm when used with different servos.

Fig. 163

Fig. 164

Fig. 165

❏

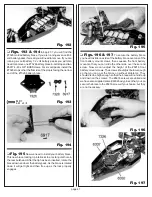

Figs. 166, 167 & 168

(1) Still working with

bag #6-13 we will need to remove the #6712 throttle wiper

arm, one #3721 #2 x 1/4" sheet metal screw, and one #3721

#2 flat washer (there is normally an extra #3721 screw and

washer).(2)Look at the servo horns that came on or with your

servo. Fig. 166 shows five of the more common servo horns

used by the major manufacturers. The ideal design (for this

application) is the small round servo horn shown in the center

of the photo. The other servo horns will work but they do

require trimming so they will not interfere with the wiper arm

movement. (3) Push the chosen servo horn back onto the

spines of the output shaft of the servo but do not secure it. (4)

Place the #6712 wiper arm over the servo horn. Make sure

the button on the wiper arm is facing down (towards the

resistor bands). (5) The screw that was holding the servo

horn that came on your servo will go through the center slot

in the #6712 wiper arm, then the servo horn and secure both

parts to the servo. Install this screw for now but do not secure

it.(6) Now look at the bottom of the round portion of the wiper

arm. You will see a small hole. Rotate the wiper arm on the

servo horn until the small hole will line up with one of the holes

in the servo horn. You have a little up and down movement

with the wiper arm to help make sure every thing will line up

correctly with a hole. (7) When you find a hole that lines up,

go ahead and secure the wiper arm to the servo horn with the

#3721 screw and #2 washer. (8) Now remove the servo horn

mounting screw then the servo horn/wiper arm assembly. we

want to line up the wiper arm over the wide neutral band on

the green throttle resistor. The output shaft of the servo is

splined so you can rotate the servo horn assembly one spline

at a time to adjust the starting position. Once you have it lined

up correctly go ahead and resecure the servo horn assembly

with the servo horn screw.

Note: This is just a basic setup.

We will make final adjustments when we do our final

radio setup at the end of the instruction manual.

Fig. 166