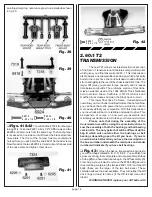

page 7

side. (2) Now reinstall one of the #6223 kingpins through

each of the carrier block/axle assemblies as shown in figs. 7

& 8. Try to center the kingpins. (3) Fig.9 shows a package of

#6299 1/8" E-clips that came from bag #7-1. They are rolled

up and held together by a piece of tape. The roll is so small

and so easy to miss, you should actually look for the

white tape instead of the E-clips. Remove two from the

package and install one on each end of the kingpin into the

grooves at each end. (If you run out of E-clips, there are more

in bags #7-8 and in the Shock Assembly parts bag.) (4) Now

take out two more E-clips and install them on the other

kingpin. We will use the remaining E-clips in the following

steps.

Fig. 7

Fig. 8

Fig. 9

#62 99

e-c lip

1/8 sh aft

❏

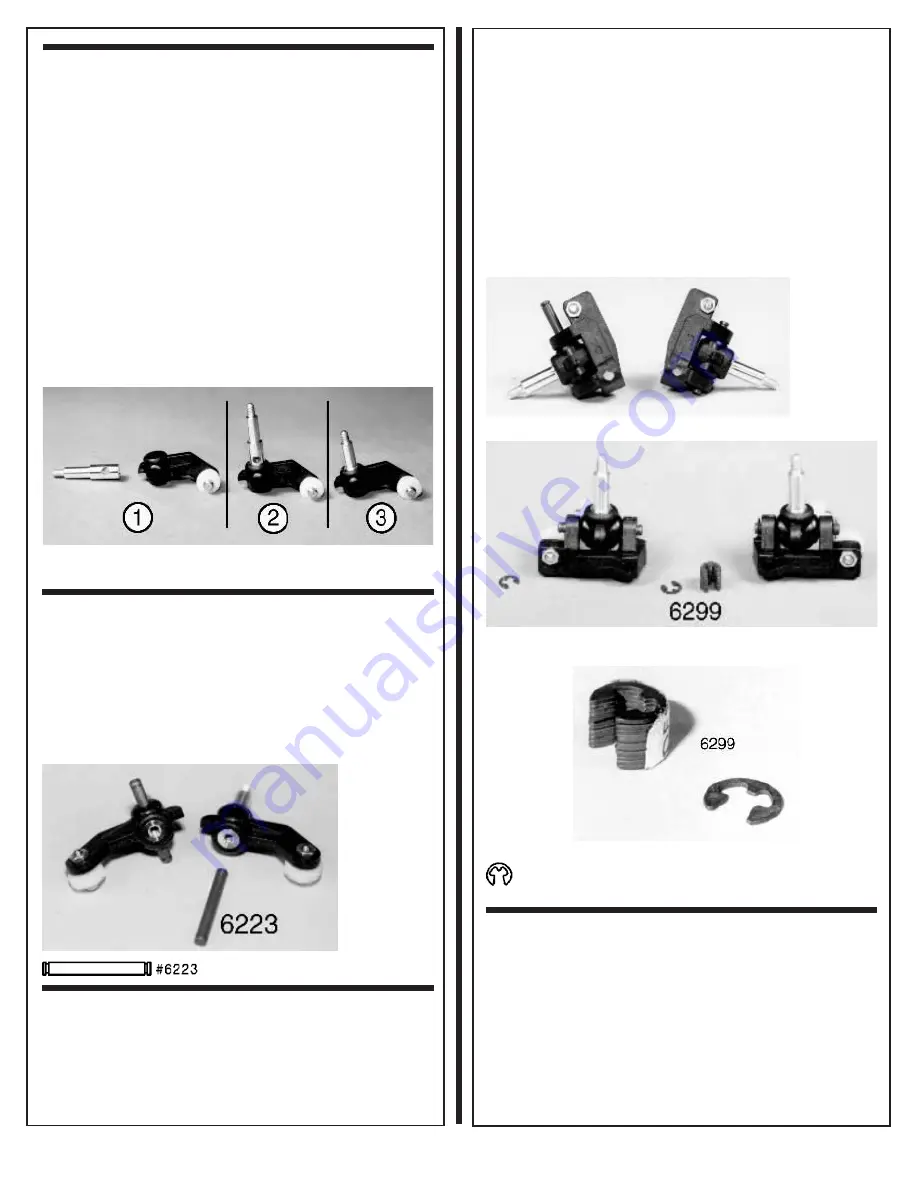

Fig. 10

(1) In bag #7-1 are two small #6951 4-40 x

1/8" socket set screws. (2) Locate your #6950 tool bag. (3)

Take out the smallest Allen wrench (.050") and use it to install

the two set screws into the #6221 aluminum front axles.

Note: Our Associated #6957 .050 screwdriver handle Allen

wrench would help here. (4) Rotate the steering blocks in the

block carriers so that you can see the threaded hole on the

back side of the #6221 aluminum front axle. Slide one of the

❏

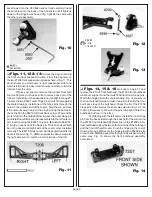

Fig. 5

You will find the two #6220 aluminum inline front

axles in bag #7-1. Your axles will look like step 1. We are

going to install one axle in each #6221 nylon steering block

(step 2), making sure that the hole in each axle lines up with

the hole in the steering block. The parts should push together

with your fingers, if they do not, then you may fit a 1/4" nut

driver over the threaded end of the axle, and then push the

axle into the steering block (step 3).

WARNING! The threads

on the end of the axle are aluminum and can easily be

damaged by the nut driver. When installed, the axle will be

fairly tight in the steering block so try to align the two holes as

you are assembling the parts.

WARNING!! Do not use

pliers on the bearing surface of the axle. This can

damage the axle surface so that the bearings will no

longer fit. It is safer to push the axle out of the steering

block and start the alignment process over if it will not

turn. Repeat the process for the second axle and steering

block.

Fig. 5

❏

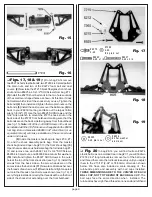

Fig. 6

In bag #7-1 you will find two #6223 kingpins.

This bag contains several different length pins, so match the

pins to the actual size drawing at the bottom. Now check that

each kingpin will go through both steering blocks and axles.

If you don’t do this it will be almost impossible to get the

kingpin to go through the #6210 carrier block and the steering

block and axle when we assemble them. Once you have

checked the fit of the kingpins remove them again.

Fig. 6

❏

Figs. 7, 8 & 9

(1) Take the two #6210 carrier

blocks and install the steering blocks and axles into each one.

Both steering block ball ends will be on the same side when

installed correctly and the raised side of the angle on the

bottom of the #6210 carrier block will be away from the ball