page 43

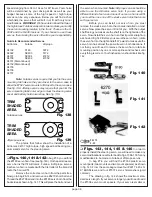

Fig. 174

❏

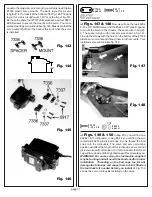

Fig. 175, 176 & 177

Now we can begin to

connect the wire harness for the throttle resistor and battery

pack. (1) In bag #6-13 you will find a small 2 inch piece of red

16 guage wire. (2) Solder one end of this wire to the #6714

brass bypass tab. Then solder the other end to the closest tab

on the #6711 throttle resistor. This will be the positive

terminal on the resistor. You can shorten the wire to improve

the efficiency and appearance of the connection. See fig.

175.

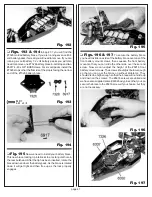

(3) Next remove the #6747 battery input power

harness (with B.E.C. plug). Solder the large red wire to the

positive tab on the throttle resistor. Now solder the large black

wire to the negative tab on the same throttle resistor Fig. 176

shows this harness installed on the throttle resistor. (4) The

last harness we need is the #6745 motor output plug. For this

plug we will solder the red wire to the #6712 brass wiper arm

on the servo. We will then solder the black wire to the

negative tab on the left side of the throttle resistor. Fig. 177

shows this harness plug installed. Now connect the #6745

motor output plug to the motor plug that is soldered onto the

motor. Your mechanical throttle control is now assembled

and installed. We will check the setup and make any

adjustments in the final adjustments section later in the

manual.

Fig. 175

Fig. 176

Fig. 177

❏

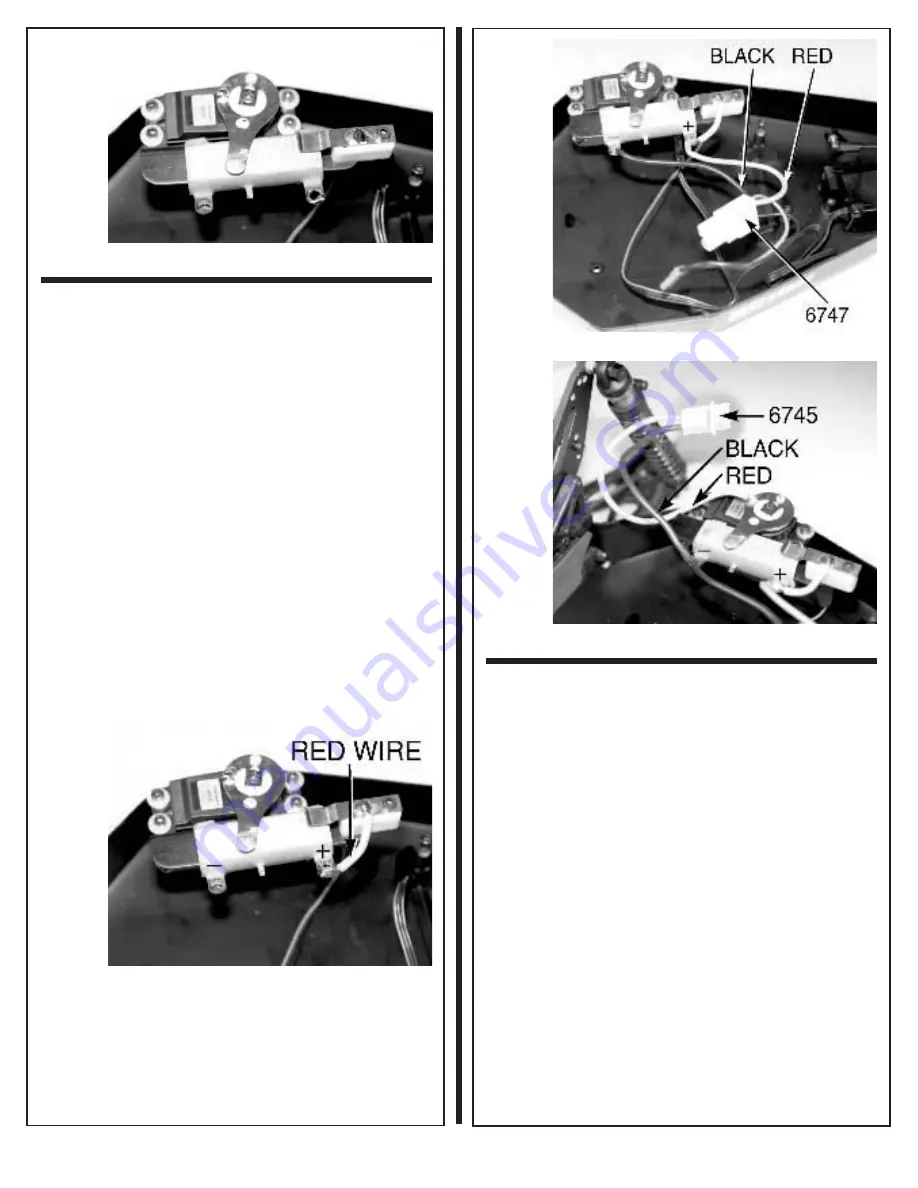

Fig. 178

FOR BALL BEARING KITS we are now

going to install the electronic speed control. If you have not

decided on a speed control yet, we recommend using a name

brand like LRP, Novak, or Tekin. We consider this to be the

top brands from Europe and the U.S. As long as you stay with

a quality brand you should have no problems.

NOTE: Bush-

ing kit owners will need to follow this step if you ever

decide to upgrade to an electronic speed control.

In your kit bag you will find a two strips of double stick

servo tape. trim a piece to fit the bottom of the ESC (electronic

speed control) case. Peel the backing from one side and

secure the tape to the case. You want to mount the ESC in

the back left corner of the chassis as shown in the photo. Try

to mount the ESC so that air can flow through the FET's or

heat sinks, if possible. Now cut a small piece of double stick

tape to fit the on/off switch on the ESC and use it to secure

the switch in the position you want.