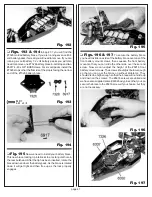

splines on the servo. Remount and then recheck the

position of the wiper arm. Remember you can use the trim

knob to fine tune the adjustment to get it correct. Next test

the throttle by squeezing the trigger. Does the wiper arm go

all the way over and under the throttle bypass tab? Every-

thing is correct if you contact the bypass and the wiper arm

does not come off the resistor on the brake side.

Note: If

you have a radio system that does not have the 70/30

setting or switch but only the older 50/50 setting, it can

still be made to work. This system just requires a little

more time and effort to setup correctly. For this sys-

tem you will have to have the wiper arm slightly to the

left of the neutral band. You will use the throttle trim to

adjust the wiper arm back over the neutral band. You

will have to use almost all of the trim to accomplish

this so that the wiper arm should not slip off the

resistor when full brake is applied.

If you have an electronic speed control (ESC)

follow the speed control manufacturers' manual to make all

settings and adjustments.

❑

Step 9

Now turn the car switch OFF. A word of

caution here. Have the truck sitting up on a block or work

stand so the rear wheels cannot touch anything before you

turn the car switch back on to check the speed control and

motor operation. If you have not connected your motor

plug during the testing of your speed control settings your

motor into the speed control motor plug. Recheck the

speed control settings with the motor now connected.

❑

Step 10

When you are done setting the speed

control (and probably playing with the throttle) turn the on/

off switch OFF.

❑

Step 11

The transmitter switch must always be the

FIRST SWITCH TURNED ON and THE LAST SWITCH

TURNED OFF.

YOUR TRUCK IS NOW READY TO RUN!

RC10T2 TRUCK

MAINTENANCE

You will find your RC10T2 truck will give you many

more hours of trouble-free operation. Even so you should

periodically check all the moving parts: front and rear A-arms,

steering blocks, steering linkage, shocks, and so on for wear,

missing or loose parts. Also if any of the moving parts should

get dirt in them (lets say in the arm hinge pins) then the truck's

handling can suffer greatly. Replacing, tightening or cleaning

of the parts in questions will greatly improve the performance

of your truck.

MOTOR TROUBLESHOOTING. Because the truck is

designed to run in the dirt it is possible the dirt can cause motor

problems. This means that if you are having problems with

your motor you will need to check this things first:

1) If the motor does not run at all you should check the

wiring connections first. Are all the wires and capacitors

connected properly? Are all the solder connections in good

shape? A bad solder connection will have dull finish or it will

be rounded under the edges. (This means the solder has not

properly bonded the parts together.) Pull on the wires to make

sure that the connections are really solid.

2) A sticking brush could be caused by dirt or the

brush braided wire getting caught or hung up on the brush

holder. Either of these can prevent the brush from being axle

to slide in and out inside the brush holder so that it is making

contact with the commutator at all times. You can normally

correct either problem by pulling the brush out of the brush

holder a very small distance and then letting it snap back into

the brush holder from the spring pressure of the brush spring.

To prevent these problems in the future you should clean the

brushes, holder and commutator. You should also re-route

the brush wire over the top of the brush holder and then down

into the spring slot on the right side of the brush holder (behind

the spring). This way the brush wire cannot get caught or bent

over the outer edge of the holder. Always keep in mind that the

brushes need to be able to move freely in the brush holder.

3) To check for a shorted motor, you will want to remove

the motor pinion from the motor. This will prevent the the

vehicle from getting away from you or causing any damage.

With a fully charged battery pack, turn on the radio transmitter

followed by the car. Now give the car full throttle. Does the

motor seem to reach full speed? If you are using a high

revolution motor, it should sound like it is turning at a very high

speed. Next, with the motor still running, place one finger on

each side of the motor end bell so that one finger is contacting

the positive side and the other is contacting the negative side.

We are not trying to make electrical contact, we are just going

to be looking for excessive heat. If the motor is shorted it will

get extremely hot on one of both sides of the end bell in less

than a minute. This means it will become hot enough to burn

your finger at the end of the minute. If this is the case then you

would need to send us the motor along with a copy of the

purchase receipt (that shows the date of purchase) so that we

can inspect the motor for defects. We will then test the motor

to confirm your problem Upon confirmation of the defect we

will send you a replacement motor. Following the above

proceedures will help to prevent your losing unnecessary time

in being able to enjoy your new car kit.

MOTOR MAINTENANCE. After every 2 to 3 runs,

remove the brushes from the holders and inspect the tips for

wear and/or burning. If you notice any wear, replace the brush

with a new pair. To inspect for a burnt tip, look at the side of

the brush on the contact end. If it is a burnt blue color, then the

lubricant in the brush has been burnt away; new brushes

should be installed. These are important steps, for worn or

burnt brushes can cause irreparable damage to the motor

commutator. Changing brushes frequently will help maintain

the life of your motor. For stock motors we recommend our

#738 motor brush; for standard brush modified motors we

recommend our #737 motor brush. And for laydown brush

modified motors use our #760 motor brush.These are off road

compounds, giving you excellent motor life and good power,

but we do have other compounds for different applications. At

the same interval you should carefully clean the motor. One