35

:: Chassis Tips

:: Front End Tips

Gearing:

Follow your motor manufacturer’s recommendations for gearing options.

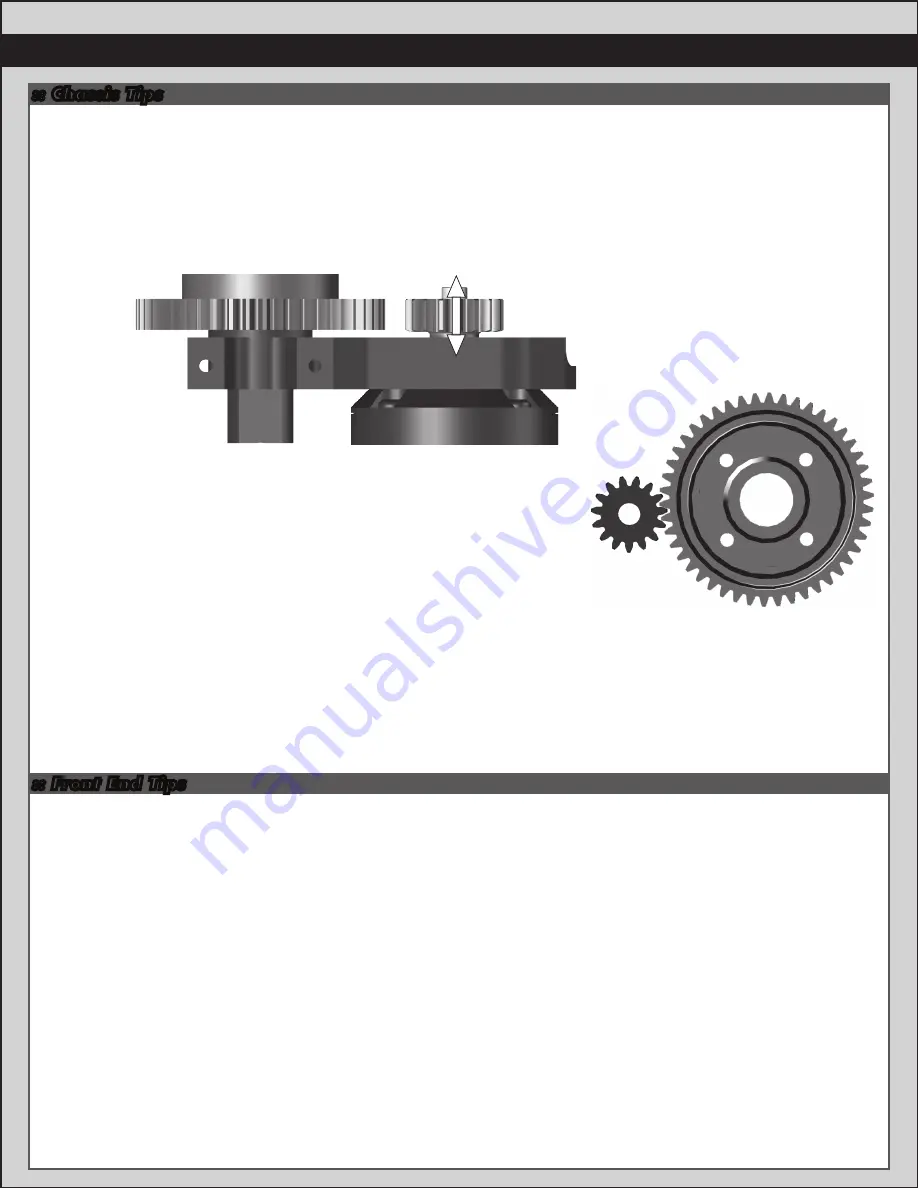

Gear Mesh:

To correctly set your gear mesh, follow the steps below:

1. Loosen the set screw on the motor’s pinion gear. The set screw can be accessed through the slot on the side of the

motor mount slide, opposite the spur gear. Slide the pinion on the motor shaft until the gear face of the pinion is entirely

aligned with the gear face of the spur gear (see diagram). Tighten the set screw while ensuring it is aligned with the flat

face on the motor shaft.

2. Loosen the two motor screws until the motor is able to move freely.

Slide the motor as far as it can go towards the spur gear, ensuring that the

teeth of the pinion and the spur gear are interlocking. Back the motor off a

tiny bit (approximately 0.5 mm), and tighten the screws that lock the motor

in place. Proper gear mesh has been achieved when the teeth are meshing

closely, but the gears still have a small amount of play between them. If you

hold one gear, you should be able to rock the other gear back and forth a

small amount. If there is not “free play”, your gear mesh is too tight and you

should back off the motor a little farther.

Differential Fluid:

Team Associated includes a complete bottle of 5,000cst diff oil.

You can also provide your own oil and try one of the optional setups.

Standard differential fluid setup: Front = 5,000cst; Center = 5,000cst; Rear = 5,000cst.

Optional diff setup 1 (high grip track): Front = 5,000cst; Center = 10,000cst; Rear = 5,000cst.

Center Differential:

Use the standard setup for most cases. Some racers will try thicker oil (7,000-10,000cst) when greater acceleration

is needed. This is typically done on very smooth tracks since thicker fluid can reduce handling in bumpy conditions.

Front Differential:

Use the standard setup for most cases. Try 7,000cst to 10,000cst to get less low speed steering and better

acceleration out of turns.

Kickup Bushing:

Generally more kick-up will provide better handling in the bumps and have better straight line acceleration.

Less kick-up will provide more all around steering and have a more aggressive feel.

Caster:

The standard caster block insert setup is for 16 degrees. The standard inboard kick-up is 9 degrees (2-dot up insert

in A-plate). You can reduce the caster using 14 degree inserts (also move both upper cone washers in front of the ball

joint) for smoother steering. Changing to 18 degree inserts (also move both upper cone washers behind the ball joint)

will typically provide more steering on power but reduce handling in bumpy conditions.

Front Upper Pivot Insert:

The standard setup is to use 2-dot up in the tower and 1-dot in the top plate. It is recommended to maintain a 1 dot

gap (1mm per dot) front to rear when using 2-dot up in the A-Plate. Reducing the A-Plate insert to 1-dot allows the use

of same dot number insert in both tower and top plate. Going up to 3-dot up in the tower will give more turn in, but less

steering on power/exit. Going down (1-dot, 2-dot down) will reduce turn in, but give more steering on exit.

Front Camber Link-Outer:

The standard short location will work the best for most tracks. Going to the long front link will give you more steering,

but can make the car less predictable in bumps and exiting turns.

Pinion

Spur Gear

Pinion

Spur Gear

Summary of Contents for SC8.2e

Page 1: ...6 12 ...

Page 50: ...50 Notes ...