9

high speeds blades that compress and accelerate air into the distribution system. They are capable of

producing large volumes of air in the 10 psi range. These units are typically the air supply of choice for

facilities containing multiple High Pressure PolyGeyser

®

filters.

The common oil-less shop compressors can be used to backwash a HPPG unit. Commonly capable of

producing pressures in excess of 100 psi, these units are capable of overcoming any pressure produced

by a water pump. These units are powerful piston units that produce a relatively small volume of air at

extremely high pressures. Normally installed with the delivery pressure regulated down to 20 psi, these

compressors can be set to match virtually any water pump. Inexpensive shop compressors are not

designed for continuous duty. A compressor tank is usually associated with the compressor unit and

the motor operates intermittently to maintain the tank pressure. These units should be sized with a

delivery capacity 5-10 times higher than the backwashing air capacity to assure the compressor operates

only periodically. (Note: These compressors are typically rated in terms of cubic feet per minute at

100+ psi whereas backwash demands are rated in cubic foot per hour at 20 psi). Shop compressors are

generally noisy and are poorly designed for a wet environment. Under normal circumstances, the air

pressure delivered to a unit does not influence the pressure experienced by a HPPG hull. Air input into

the unit merely displaces water; there is no potential for internally damaging the unit by over pressuring

the charge chamber. However, the pressures generated by a poorly adjusted shop compressor (I.e. the

discharge pressure regulator is set too high) are clearly capable of catastrophically cracking hull rated for

20 psi. This can occur if the unit is “dead headed” by closure of an outlet line trapping the pressure

between an inlet check valve and the closed outlet valve

. Thus, units employing shop compressors for

backwashing must be equipped with a pressure relief valve on the air line or a water line immediately

adjacent to the hull on the influent or effluent side.

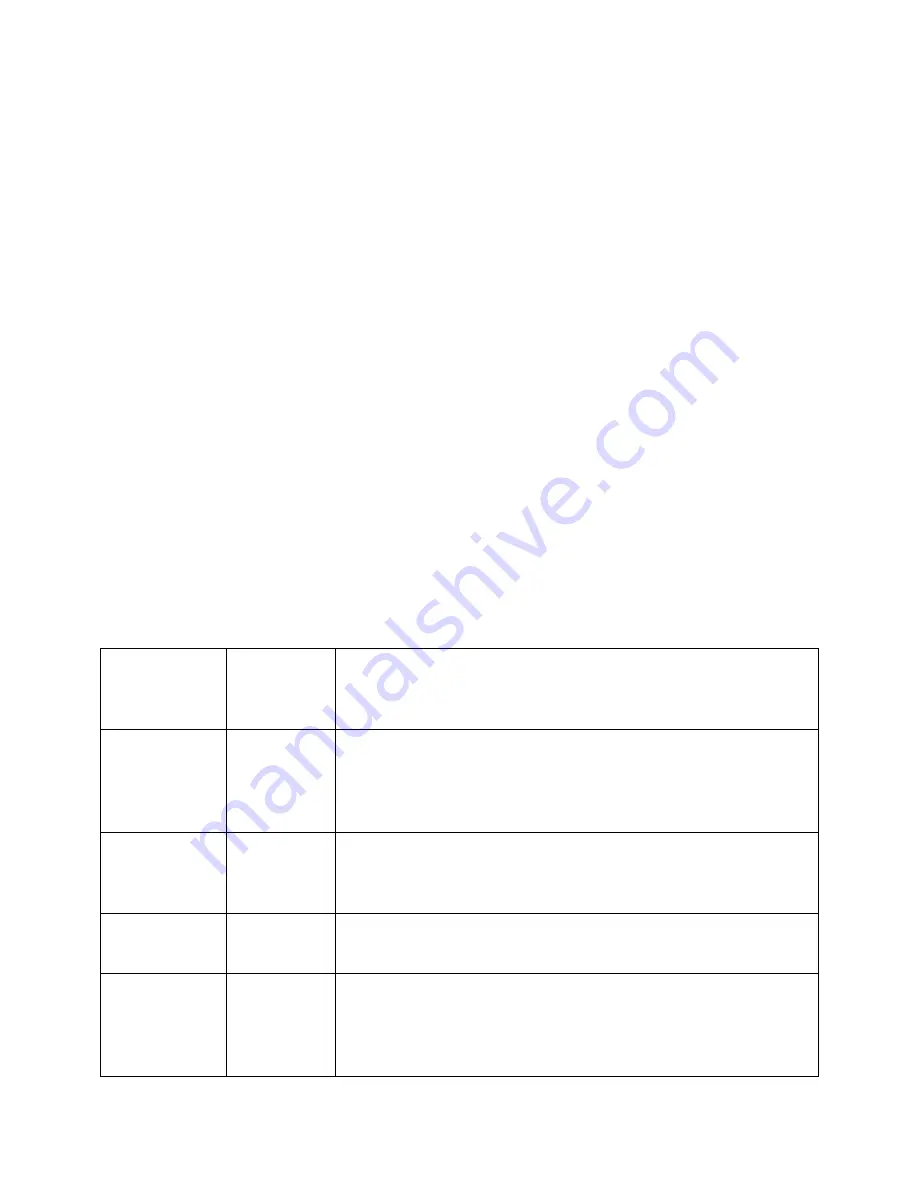

Pump

Typical

Pressure

Range

Comments

Linear Air

0-10 psi

Excellent for backwashing of filters that are nor back pressured

by downstream constrictions, may be over powered by shutoff

head of water pump so should be protected by check valve.

Energy efficient.

Piston

0-30 psi

Generally suitable for all HPPG applications. Capable of

generating pressures in excess of hull pressures thus cannot

be overcome by properly sized water pump.

Rotary vane

compressor

0-15 psi

Suitable for low pressure airlift applications and simplified

pumped configurations. Produce volumes sufficient to

Shop

0-150 psi

Oil free shop (piston) compressors with tank work well as a

backwash air supply provided they are sized large enough to

provide for extended cycle time. Tend to be noisy and over

pressurized, but, inexpensive.