C

H A P T E R

3

O

P E R A T I N G

T H E

6 7 1 0 D

1 0 9 4 0 1 B

6 7 1 0 D G

R I N D E R

O

P E R A T O R

S

A F E T Y

M

A N U A L

8 1

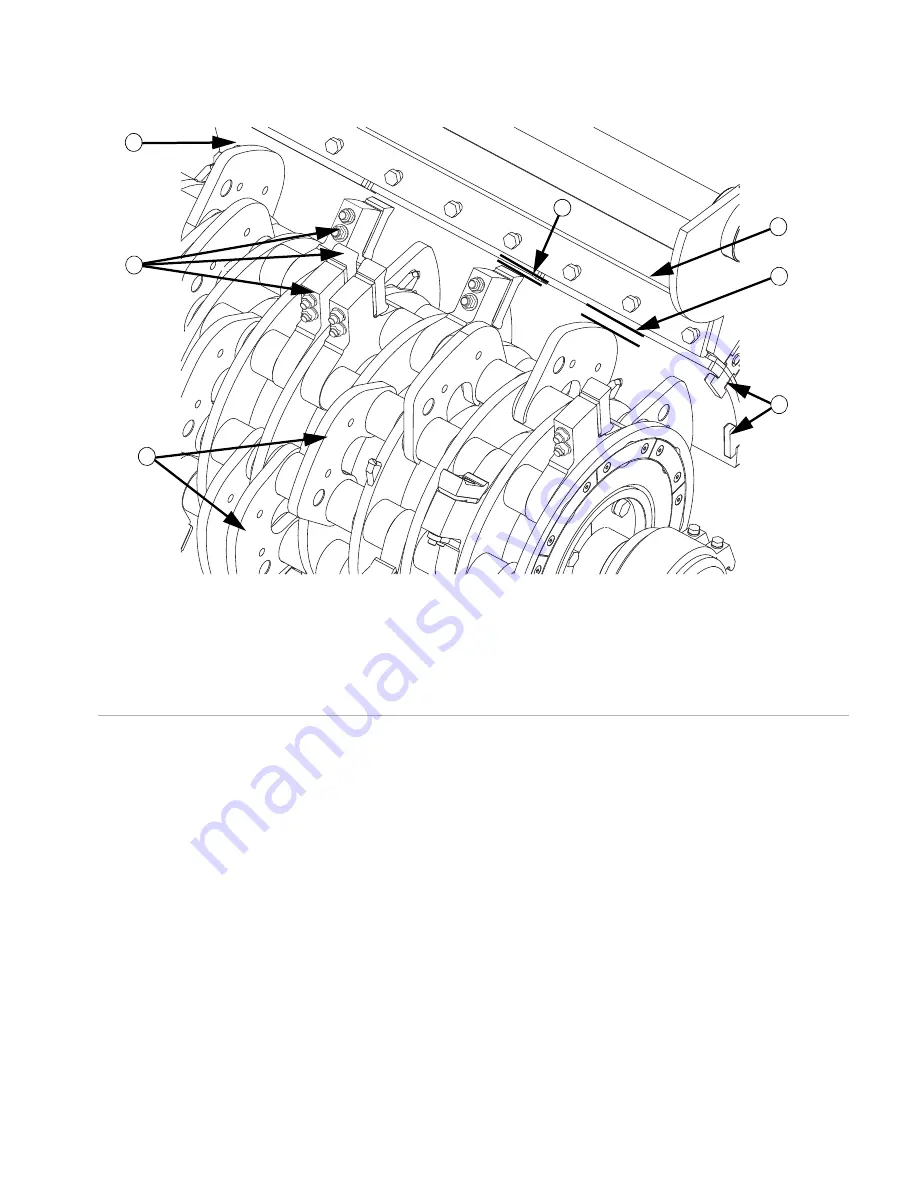

Checking the Bits

Check the bits every day for condition and tightness.

Worn or broken bits produce poor quality output, slow

down production, use more power, and are a safety haz-

ard.

If you are processing highly abrasive material such as

shingles, check the wear on bits, bit spacers, nuts, and

bolts

every hour

.

For instructions on replacing, reversing, and hard-fac-

ing the bits, refer to Section 5000 of the

Maintenance

Manual.

1

WARNING

Crushing or pinching hazard.

Follow all precautions (see the Working Safely

chapter) before allowing anyone near the grind-

ing point or near the feed chain.

Before checking the bits, shut down the engine,

disconnect and lock out the battery disconnect

switch, and safety-lock the compression roll.

F04461

2

1

Figure 86:

Pinned Rotor

6

5

1. Grate Section #1

2. Bits and Holders

3. Bit-to-Anvil Gap

4. Anvil

5. Gauging Bar-to-Anvil Gap

6. Grate Retainer

7. Gauging Bar

3

4

7

Summary of Contents for Peterson 6710D

Page 6: ...C O N T E N T S 4 67 1 0 D G R I N D E R O P E R A T O R SA F E T Y M A N U A L 109401B ...

Page 158: ...16 2 67 1 0 D G R I N D E R O P E R A T O R SA F E T Y M A N U A L 109401B ...

Page 166: ...I N D E X 17 0 67 1 0 D G R I N D E R O P E R A T O R SA F E T Y M A N U A L 109401B ...

Page 167: ......