C

H A P T E R

3

O

P E R A T I N G

T H E

6 7 1 0 D

1 0 9 4 0 1 B

6 7 1 0 D G

R I N D E R

O

P E R A T O R

S

A F E T Y

M

A N U A L

7 7

Inspecting the Machine

During Periodic Daily

Shutdowns

Clean the undercarriages frequently to prevent soil and

debris from packing the undercarriage components, as

this increases the load on track components and contrib-

utes to a shorter track life.

One or more times each day, check the wear and condi-

tion of the bits and related wear parts, such as gauging

bars, anvil, and grates. Also check the feed chain, floor

plates, and related parts. These checks are described in

this section.

For detailed wear indicators for the grinder assembly

wear parts, refer to Section 5000 “Processor System” in

the

Maintenance Manual

.

To prepare the feed and grinder assemblies

for inspection:

1.

Restart the engine if you have already shut down.

Set the engine speed to low idle.

2.

Raise the compression roll to its maximum height.

1

WARNING

Crushing hazard.

Never remove the locking stop or pin from the

inside or while a person is in the hopper or near

the point of operation.

3.

Set the safety locking stops for the compression roll

housing. See “Compression Roll Safety Locking

Stops” on page 38.

4.

Shut down the engine.

5.

Lock out the battery disconnect switch.

To inspect the feed and grinder assemblies:

1.

Remove any compacted material from the material

processing area.

2.

Check the following items carefully:

Feed chain link pins

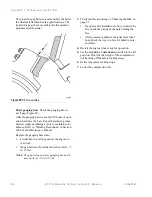

(Figure 76). Inspect the link

pin heads for wear against compacted material on

the inside walls of the hopper. Also, make sure the

feed chains are aligned on the tail pulley flanges.

Figure 76:

Feed Chain Link Pins at Feed Tail Pulley

Feed chain tension

. Feed chains stretch as they

wear. Using a flashlight, stand in front of the tail

pulley and look under the hopper floor. The feed

chain should be off the floor plate for about 3 ft

(1 m) behind the tail pulley.

Hopper floor

. Check the adjustable gap at the tail

pulley:

•

Ensure the gap between the hopper floor and

tail pulley is less than 3/4 inch (19 mm), as

shown in Figure 77.

•

Check the bolt tension for securing the floor.

Figure 77:

Hopper Floor/Tail Pulley Gap

F05603

1. Feed Chain Link Pins

2. Hopper Inside Wall

3. Tail Pulley Flange

1

2

3

1

1

1

3

F05604

Summary of Contents for Peterson 6710D

Page 6: ...C O N T E N T S 4 67 1 0 D G R I N D E R O P E R A T O R SA F E T Y M A N U A L 109401B ...

Page 158: ...16 2 67 1 0 D G R I N D E R O P E R A T O R SA F E T Y M A N U A L 109401B ...

Page 166: ...I N D E X 17 0 67 1 0 D G R I N D E R O P E R A T O R SA F E T Y M A N U A L 109401B ...

Page 167: ......