Aston Technologies Inc.

www.astontechusa.com

- 7 -

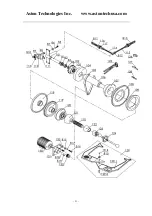

4.2.1 Tire mounting

①

Fix the screw mandrel on the

main shaft.

②

Install the tire tested on the

main shaft beside the adapter.

③

Select the proper cone to fit

over on the main shaft.

④

Tighten with lock washer nut.

4.2.2 Tire mounting with special flange

①

Install the flange on the

adapter, tighten it with bolt.

②

Fix the screw mandrel on

the main shaft.

③

Select the proper cone to fit

over on the main shaft.

④

Tighten with lock washer

nut.

Caution:

1. When fasten the large sized tire, rotate the tire 180°, fasten it

again to make sure the centre of tire positions are accurate.

2. Inner plane of special flange must accord with adapter.

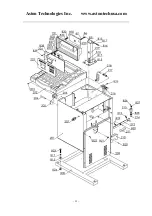

4.3 Dimension input

Summary of Contents for ADP-2000A

Page 1: ...Aston Technologies Inc www astontechusa com 1 Wheel Balancer User s Manual Model ADP 2000A...

Page 21: ...Aston Technologies Inc www astontechusa com 21...

Page 22: ...Aston Technologies Inc www astontechusa com 22...

Page 23: ...Aston Technologies Inc www astontechusa com 23...

Page 24: ...Aston Technologies Inc www astontechusa com 24...