www.astontechusa.com

17

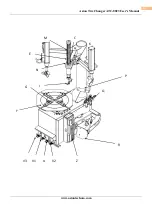

Aston Tire Changer ATC-8823 User’s Manual

1

Whether the power supply voltage is consistent

with the requirements of the equipment

2

Whether the components are installed correctly

3

Whether the bolts, screws, nuts are tightened

Note:

Please fill in the inspection item list after the installation is finished.

3.5 Commissioning and debugging

3.5.1 Commissioning

◇

After the installation of the machine but before the connection with the power supply, it

is necessary to determine the user's power supply, the gas source and the requirements

of the machine is consistent.

◇

The machine is connected to the circuit, the circuit must be fitted with a fuse that is in

line with the operating rules. The automatic circuit breaker of 25A is required to be

operated by professional personnel. The power plug of the tire changer is provided with

the customer.

◇

The compressed air system is connected to the machine by a pipe joint on the right side

of the tank.

3.5.2 Debugging

◇

Step 1: turn on the power and gas supply, depress the Turntable Rotation pedal, turntable

should be clockwise. Raise the Turntable Rotation pedal, the turntable should be anti-

clockwise rotation. (If the turntable is opposite to the specified rotation direction, the

position of the two lines in the three-phase plug should exchange position.)

◇

The second step: depress the Bead Breaker Pedal, start the Bead Breaker device; when

the pedal is released, the Bead Breaker device to return to the original position.

◇

The third step: depress the Jaw Clamp Pedal, open the 4 clamps; release the Jaw Clamp

Pedal, the Jaw Clamps returns to the original position.

◇

The forth step: Swing Arm / Vertical Shaft / Mount-Demount Head Assembly