31

of

54

TECHNICIANS' manual

ENGLISH

Core200

8.

MAINTENANCE AND CLEANING

8.1

Safety precautions

Carefully read the instructions provided in chapter I.

8.2

PPE features

When maintaining and cleaning the machine, the following PPE is requiredI:

The use of protective gloves is mandatory

Ambient maintenance temperature

5 - 35°C

8.3

Maintenance

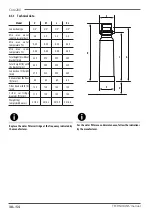

8.3.1 Scheduled maintenance

Carry out scheduled maintenance according to the instructions in the table below, or when the "Maintenance

warning" appears on the display. If the machine is used intensively, the checks need to be performed more frequently.

Component

Type of operation

Quarterly

Yearly

PRESSURE GAUGE

•

Check the heating unit pressure, which must be between 0.8 and 1.4 bar.

•

Check the water pressure when coffee is being dispensed: check the pressure indicated on

the gauge, which must be between 8 and 9 bar.

X

FILTERS AND FILTER HOLDERS

Check the condition of the filters. Check for any damage on the edge of the filters and check

whether any coffee grounds settle in the coffee cup and replace the filters and/or filter holders,

as required.

X

DISPENSING GROUP

Replace the shower screen and group gasket as indicated in par. 8.3.4

X

WATER FILTER

Replace the water filter cartridge or replenish the water softener as often as specified by the

manufacturer.

X

WATER SOFTENER

Replace the water filter cartridge or replenish the water softener as often as specified by the

manufacturer.

X

GRINDER-DISPENSER

•

Check the ground coffee dose (around 7 grams each time) and check the degree of grinding.

The grinders must always have sharp cutting edges. There will be too much powder in the

grounds when they are deteriorating.

•

We recommend calling the Qualified Technician to replace the flat grinders after every

400/500 kg of coffee. For conical grinders, replace them after every 800/900 kg.

X

BOILER

Replace the water in the heating unit as indicated in par. 6.10

X

Summary of Contents for 10003318

Page 53: ......