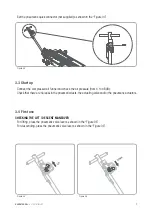

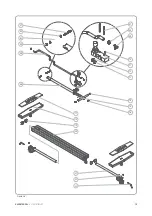

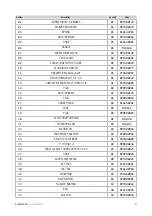

· Set the pneumatic quick connector (not supplied) as shown in the “Figure 04”.

3.3 Start up

3.4 First use

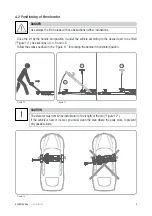

· Connect the compressed air funnel and check the air pressure (from 6 to 9 BAR).

· Check that there are no leaks in the pneumatic ducts, the actuating valve and/or the pneumatic actuators.

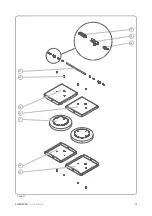

· For lifting, press the pneumatic valve lever as shown in the “Figure 05”.

· For descending, press the pneumatic valve lever as shown in the “Figure 06”.

CHECKING THE LIFT / DESCENT MANEUVER

Figure 04

Figure 05

Figure 06

7

USER MANUAL

·

AE1001 MINILIFT

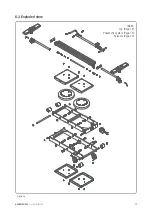

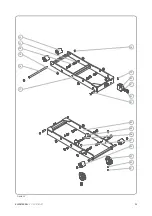

Summary of Contents for miniLIFT CLASSIC

Page 2: ......

Page 19: ...Figure 27 28 27 29 31 30 30 29 24 25 26 19 USER MANUAL AE1001 MINILIFT ...

Page 24: ...Date Maintenance plan Result Signature 7 Inspection log 24 USER MANUAL AE1001 MINILIFT ...

Page 25: ...Date Maintenance plan Result Signature 25 USER MANUAL AE1001 MINILIFT ...

Page 26: ...Date Maintenance plan Result Date 26 USER MANUAL AE1001 MINILIFT ...

Page 27: ......

Page 28: ...2018 astraballero com Spray booths Welding Benches Lifts ...