DRV-28 inverter

s Basic operartion instructions

-117-

b) Static autotuning

In cases where the load can be disconnected, it is recommended to adopt rotary autotuning

(P20.11=3) as it has high angle precision. If the load cannot be disconnected, users can adopt static

autotuning (P20.11=2). The magnetic pole position obtained from autotuning will be saved in P20.09

and P20.10.

Step 6:

Closed-loop vector pilot-run

Adjust P00.10 and speed loop and current loop PI parameter in P03 group to make it run stably in the

whole range. If oscillation occurred, reduce the value of P03.00, P03.03, P03.09 and P03.10. If

current oscillation noise occurred during low speed, adjust P20.05.

Note: It is necessary to re-determine P20.02 (encoder direction) and carry out magnetic pole

position autotuning again if the wiring of motor or encoder is changed.

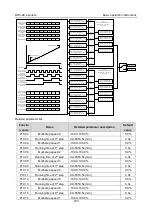

3. Commissioning procedures for pulse string control

Pulse input is operated based on closed-loop vector control; speed detection is needed in the

subsequent spindle positioning, zeroing operation and division operation.

Step 1:

Restore to default value by keypad

Step 2:

Set P00.03, P00.04 and motor nameplate parameters in P02 group

Step 3:

Motor parameter autotuning: rotary parameter autotuning or static parameter autotuning

Step 4:

Verity the installation and settings of encoder. Set P00.00=3 and P00.10=20Hz to run the

system, and check the control effect and performance of the system.

Step 5:

Set P21.00=0001 to set positioning mode to position control, namely pulse-string control.

There are four kinds of pulse command modes, which can be set by P21.01 (pulse command mode).

Under position control mode, users can check high bit and low bit of position reference and feedback,

P18.02 (count value of Z pulse), P18.00 (actual frequency of encoder), P18.17 (pulse command

frequency) and P18.19 (position regulator output) via P18, through which users can figure out the

relation between P18.8 (position of position reference point) and P18.02, pulse command frequency

P18.17, feedforward P18.18 and position regulator output P18.19.

Step 6:

The position regulator has two gains, namely P21.02 and P21.03, and they can be switched

by speed command, torque command and terminals.

Step 7:

When P21.08 (output limit of position controller) is set to 0, the position control will be invalid,

and at this point, the pulse string acts as frequency source, P21.13 (position feedforward gain) should

be set to 100%, and the speed acceleration/deceleration time is determined by the acceleration

/deceleration time of pulse string, the pulse string acceleration/deceleration time of the system can be

adjusted. If the pulse string acts as the frequency source in speed control, users can also set P21.00

to 0000, and set the frequency source reference P00.06 or P00.07 to 12 (set by pulse string AB), at

this point, the acceleration/deceleration time is determined by the acceleration/deceleration time of

the inverter, meanwhile, the parameters of pulse string AB is still set by P21 group. In speed mode,

the filter time of pulse string AB is determined by P21.29.