DRV-28 inverter

s Basic operartion instructions

-72-

Function

code

Name

Detailed parameter description

Default

value

keypad

P17.09

Motor output

torque

-

250.0–250.0%

0.0%

P17.15

Torque reference

value

-

300.0–300.0% (rated motor current)

0.0%

5.5.6 Motor parameter

Check the safety conditions surrounding the motor and load machineries

before autotuning as physical injury may occur due to sudden start of motor during

autotuning.

Although the motor does not run during static autotuning, the motor is stilled

supplied with power, do not touch the motor during autotuning; otherwise, electric

shock may occur.

If the motor has been connected to load, do not carry out rotary autotuning;

otherwise, misact or damage may occur to the inverter. If rotary autotuning is carried

out on a motor which has been connected to load, wrong motor parameters and

motor misacts may occur. Disconnect the load to carry out autotuning if necessary.

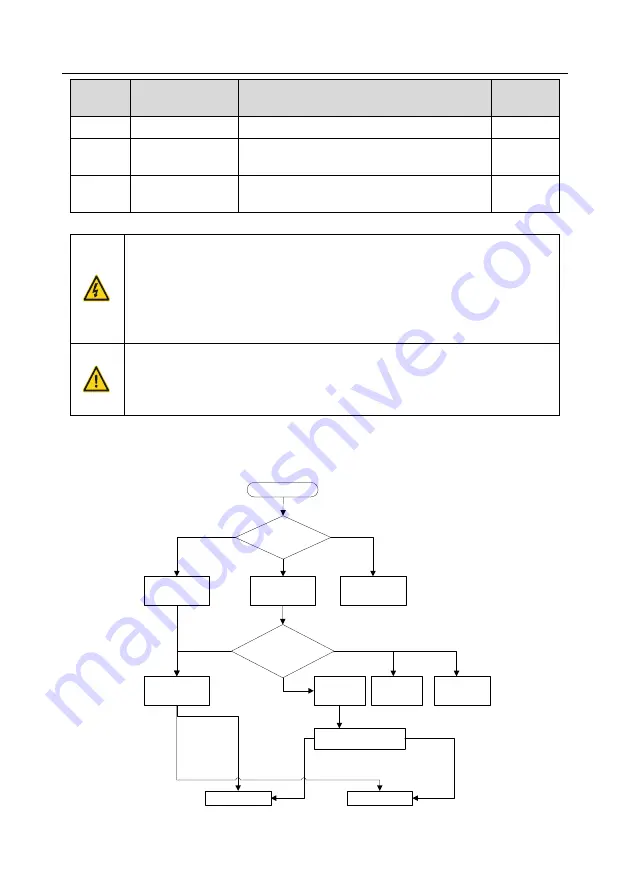

DRV-28 inverter can drive asynchronous motors and synchronous motors, and it supports two sets of

motor parameters, which can be switched over by multi-function digital input terminals or

communication modes.

Keypad (P00.01=0)

Terminal

(P00.01=1)

Communication

(P00.01=2)

MODBUS

communication

PROFIBUS

CANopen

communication

Start

Select running

command channel

(P00.01)

The switch-over

channel for motor 1 and

motor 2 (P08.31)

Terminal function 35

Motor 1 switches to

motor 2

Communication setting value

2009H

Motor 1

Motor 2

Invalid

Valid

BIT0

–

1=00

BIT0

–

1=01

P08.31 set LED

ones to 0

Ethernet

communication

P08.31 set LED

ones to 1

P08.31 sets

ones to 2

P08.31 sets

ones to 3