AS64 series AC servo drive Function codes

-109-

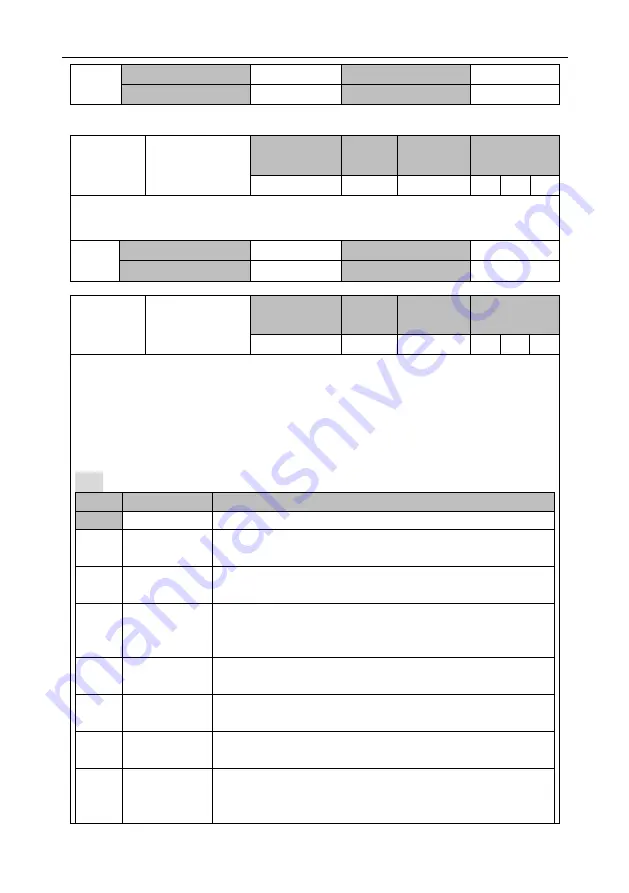

P1.08

Data size

16bit

Data format

DEC

Modbus address

1216, 1217

CANopen address

0x2108, 0x00

6.2.2 Self-adaptive vibration control

P1.19

Resonance

detection

sensitivity

Setting range

Default

Unit

Applicable

mode

0.2–100.0

5.0

%

P

S

T

This parameter specifies the sensitivity of the automatic detection on mechanical resonant

frequency. A smaller value of this parameter indicates higher sensitivity to the resonance.

P1.19

Data size

16bit

Data format

DEC

Modbus address

1238, 1239

CANopen address

0x2113, 0x00

P1.20

Resonance

detection mode

Setting range

Default

Unit

Applicable

mode

0–7

0

-

P

S

T

This parameter specifies the working mode of resonance detection, resonant frequency presumed

by the self-adaptive notch filter, and action after presumption.

If the function of automatically detecting the mechanical resonant frequency is valid (that is, this

parameter is set to 1, 2, or 3), the system automatically collects data to conduct mechanical

resonant frequency analysis and saves results to P1.21 and P1.22. You can set the notch filter

frequency according to the settings of P1.21 and P1.22 to eliminate the mechanical resonance.

Note:

You are recommended to disable the function after the gain adjustment is complete.

Setting

Function

Meaning

[

0

]

Invalid

All parameters associated with the notch filter remain unchanged.

1

One notch filter

valid

The parameters associated with the third notch filter are updated

according to the self-adaptive result.

2

Two notch filters

valid

The parameters related to the third and fourth notch filters are

updated according to the self-adaptive result.

3

Resonant

frequency test

mode

The mechanical resonant frequency is detected automatically but

the parameters associated with notch filters are not set.

4

Clearing notch

filter parameters

The parameters associated with the four notch filters are restored to

the default values.

5

Notch filter 3 →

Notch filter 1

The parameters of the third notch filter to are automatically copied to the

first notch filter and then restored to the default values.

6

Notch filter 4 →

Notch filter 2

The parameters of the fourth notch filter to are automatically copied to

the first notch filter and then restored to the default values.

7

Notch filters 3

and 4 → Notch

filters 1 and 2

The parameters of the third and fourth notch filters to are automatically

copied to the first and second notch filters and then restored to the

default values.