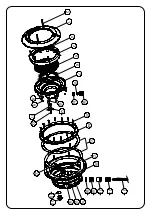

4. ASSEMBLY:

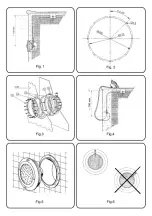

After installation of the housing and the clamp, if it is a prefabricated swimming pool, assemble the floodlamp.

To connect the floodlamp to the electric power supply insert the cable through the gland seal nut (16). Tighten the

gland seal nut until you can verify that the cable will not yield when you pull on it with your hand.

Take the precaution of leaving 1.5 m of cable wound on the base of the floodlamp (no. 7) in order to be able to

remove the floodlamp to the edge of the pool in the event that lamp replacement or handling is required. (Fig. 4).

Insert the entire floodlamp assembly in the housing (Fig 5). In order to obtain good pool lighting it is important that

the anagram of the decorative ring (no. 1) is located on the upper part (Fig 6).

Screw in the two M-6 x 80 screws (no. 2) until the fastening dog is secured in the inner walls of the housing (Fig. 7)

5. MAINTENANCE:

To remove the floodlamp to the edge of the swimming pool (Fig. 5) loosen the two DIN 966 M-6 x 80 screws (no. 2)

until the fastening dog yields sufficiently so that the floodlamp unit can be separated from the housing.

To remove the lamp, unscrew the 6 nuts (no. 9) which secure the decorative ring (no. 1) to the base of the floodlamp

(no. 7) (Fig. 8).

Remove the lamp (no. 5) from the inside of the base of the floodlamp and disconnect the two terminals, loosening

the two screws which secure them to the lamp (Fig. 9).

Change the lamp and assemble the Floodlamp, in the opposite order described in point 4 of assembly, taking special

care to:

•

Connect the cable terminals to the lamp, using the 2 screws supplied with the lamp (Fig. 10).

•

Fully centre the 110x11 O-ring (no. 6) in its seat.

•

Firmly tighten the nuts.

Attention:

•

Before any handling ensure that there is NO voltage supplied to the floodlamp.

•

The new lamp should have the same characteristics as that supplied with the floodlamp, PAR 56 300 W 12 V.

•

In order to ensure full watertightness, clean the seat of the O-ring (no. 6) for the lamp or replace the O-ring if you

observe any notches or permanent damage.

6. START-UP:

Ensure that the voltage the lamp receives is never greater than 12 V.

The floodlamp should only operate underwater while secured to the vertical walls of the pool. Never switch on the

floodlamp if it is not underwater.

7. SAFETY WARNINGS:

•

The persons who are in charge of assembly should have the required qualificatlons for this type of work.

•

Avoid making contact with the electric voltage.

•

Comply with the current standards regarding accident prevention.

•

In this regard, the IEC 364-7-702 standards must be observed. WIRING IN BUILDINGS. SPECIAL WIRING.

SWIMMING POOLS.

•

Any operation related to the maintenance or replacement of parts should be performed with the floodlamp

disconnected from the electric power system.

•

Do not handle with wet feet.

•

The manufacturer is not responsible in any circumstances for assembly, installation or start-up of any electric

components which have been inserted or handled at locations other than Its own premises.

•

It is recommended not to use sealing filler in this product and in any case. only use products specifically designed

to work with ABS. Universal products should not be used.

Summary of Contents for 23672

Page 14: ...21 27 26 19 18 16 14 15 1 2 4 3 5 6 7 25 24 23 17 28 20 18 9 8 12 10 13 11 22 16 15 14...

Page 18: ......

Page 19: ......