OM226142 rev C

43

6.9 THERMAL

COMPENSATION BATTERY CHARGE

It consists of a temperature thermal sensor to be installed in the battery room (or battery

cubicle) in order to detect the operating temperature.

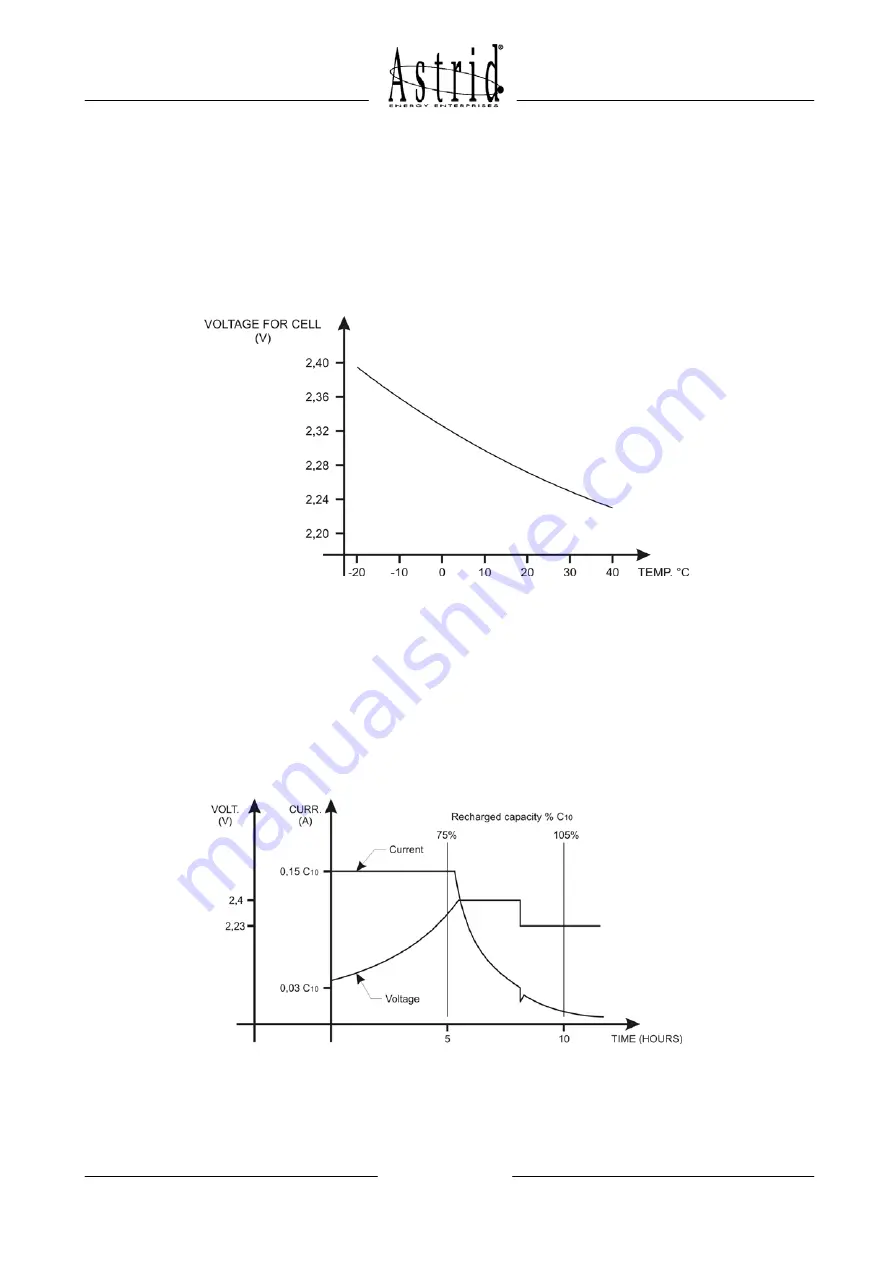

This transducer is able to modify the charging voltage according to the typical curve

supplied from the battery manufacturer. It is normally used for sealed batteries, which are

particularly temperature sensitive.

This type of regulation ensures a proper charging voltage to the batteries in order to

improve their operating life.

Picture 34 – Charging voltage vs. temperature

The temperature sensor is housed inside a plastic tube and already provided with a three-

pole cable that must be connected to an interface card installed next to the UPS’ terminal

board section. The temperature sensor can be installed at a maximum distance of 15

meters from the UPS.

6.10 BOOST

CHARGE

This type of charge, according to DIN41773, is used with vented lead acid (open type) or

Ni-Cd batteries that have a wide voltage range (Pb: 2,2÷2,7 V/cell).

Picture 35 – BOOST charge diagram

In order to design the correct number of cells, the following table shows the voltage limits

of the UPS. The maximum capacity is a function of the maximum recharging current, that

can be found in the technical specification.