17

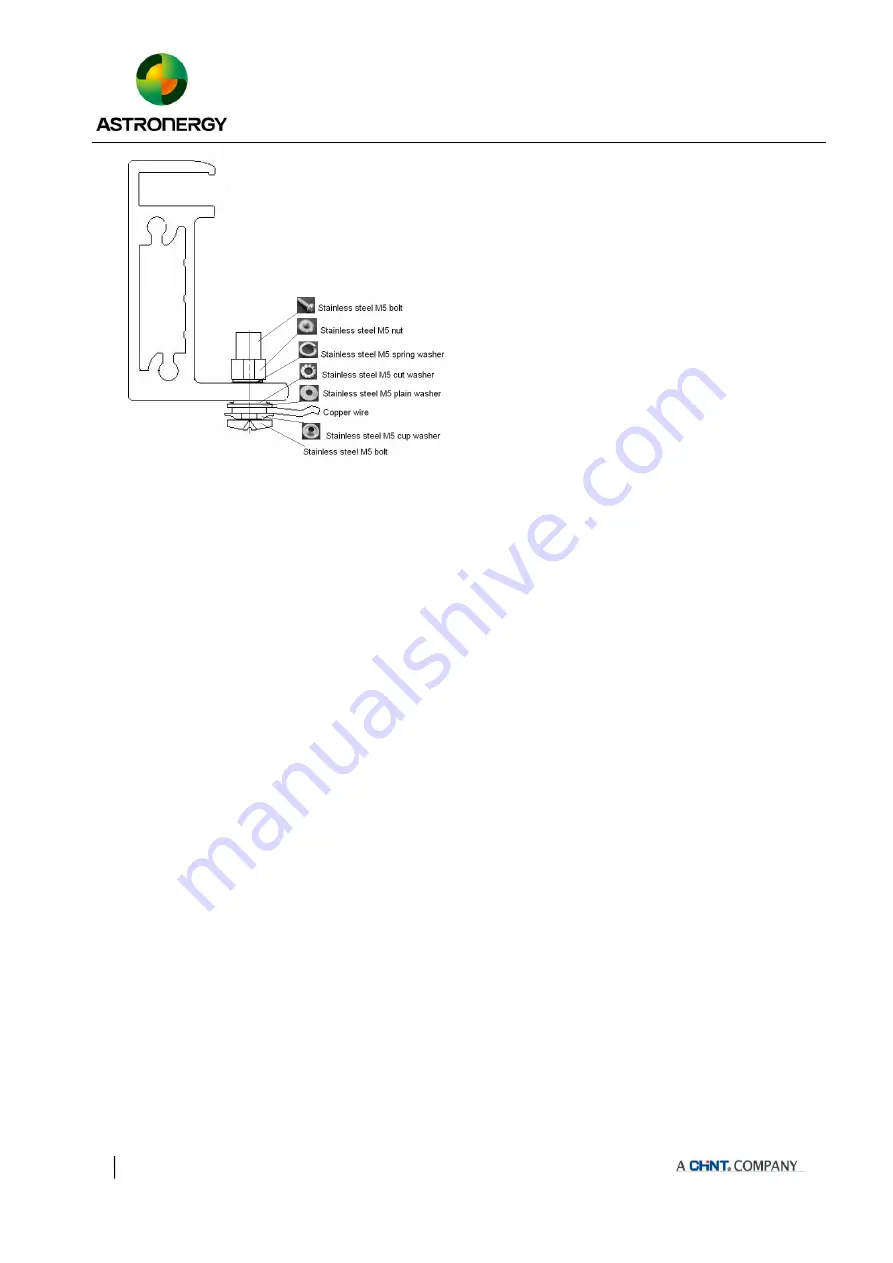

Fig. 15 Grounding the aluminum frame with copper

wire

The grounding requirements must be checked in

accordance with the applicable regulations and

standards before work is started.

Use the marked 5.5 mm grounding holes to ground

the anodized frame. Use one M5 nut, two M5 cut

washers, one M5 plain washer, one M5 spring

washer, and one M5 bolt and the copper wire. All

nuts, bolts, and washers shall be of type M5 and

made of stainless steel (Fig. 15).

Insert the bolt through the cup washer and wrap the

copper wire around the bolt. (Note that the copper

wire cannot be attached directly to the aluminum.)

Insert the bolt through the cut washer and then

through the hole in the aluminum frame.

Add the spring washer and nut on the other side of

the bolt and tighten to secure all parts. The

tightening torque should be 4~4.5N•m.

!

ATTENTION

Use UL-467 certified bonding and grounding

devices, including Burndy (formerly Wiley

Electronics) Washer Electrical Equipment Bonding

(WEEB) and similar devices, such as barbed

washers, that meet the requirements of UL-467 and

is suitable for electrical bonding and grounding of

PV modules.

Other grounding methods may be used when the

racking system is tested following the UL 2703

requirements.

Do not drill any additional grounding hole on the

frame of the modules. The frame rails have

pre-drilled holes marked with a grounding sign.

These holes should be used for grounding purposes

and should not be used for mounting the modules.

7

Maintenance

PV modules must be inspected and maintained

regularly, especially during the warranty period, which

is the responsibility of the user. This helps to find and

figure out problems in time and ensure the safe and

effective operation of the PV system.

7.1

Routine Inspection

PV modules in PV arrays should be inspected regularly

for damages, such as glass breakage, cable breakage,

junction box damage, cell cracks, and backsheet

breakage and other factors that cause functional and

safety failures of PV modules. If any of the above

problems occurs, the supplier should be notified to

replace the broken module with a new one of the same

type in time.

It is recommended to perform preventive inspection

every 6 months and not to replace the components of