Chint Solar (Zhejiang) Co., Ltd. | Add:1335 Bin´an Road, Binjiang District, Hangzhou | P.C: 310053

Tel: 0086-571-5603 1888 | Fax: 086-571-5603 2316 | Website: http://energy.chint.com/

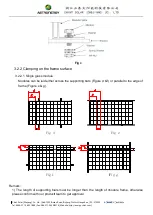

2) As for above figure d, the solid red rectangles indicate primary clamp installation positions and

the center positions of long frames where clamps can be added for additional support.

3) Illustrations (figure d

、

e

、

f

、

g) of the four different methods for clamping modules on the frame

with aluminum clamps. “ ”means the aluminum clamp’s permissible clamping range. The

recommended installation position shows as below table. Note: “---” means Fig f &Fig g methods

will be not suitable for the module type.

Module Series

Dimension

A*B*C

J

K

L

M

Note

CHSM6610M, CHSM6610M/HV,

CHSM6610P, CHSM6610P/HV,

CHSM6610M(BL)

1648*990*35

1650*992*35

408

198

---

---

3.2mm glass

1648*990*40

1650*992*40

408

198

---

---

3.2mm glass

CHSM60M-HC, CHSM60P-HC

CHSM60M(BL)-HC

1666*992*35

1675*992*35

408

207

---

---

3.2mm glass

1692*1002*35

415

215

---

---

3.2mm glass

CHSM6612M,CHSM6612M/HV

CHSM6612P,CHSM6612P/HV

1954*990*45

1960*992*45

489

299

50

200

3.2mm glass

1954*990*40

1960*992*40

489

299

---

---

3.2mm glass

1954*990*40

1960*992*40

489

299

---

---

4.0mm glass

CHSM72M-HC, CHSM72P-HC

1986*992*40

2018*1002*40

505

315

---

---

3.2mm glass

2000*992*40

510

315

---

---

3.2mm glass

To fasten the module:

a) Place the module on the two supporting bars (not provided). The bars should be made with

stainless material and treated with an anti-corrosion process (e.g., anodic oxidation

treatment) or aluminum profile. Each solar PV module needs at least four clamps to fix. Do

not make the clamp contact the glass directly or make the aluminum frame deformation in

the installation process, and avoid the shadow of solar PV components.

b) The bar’s top surface contacted with module frame should come with grooves compatible

with an M8 bolt.

c) If the bars do not come with grooves, holes of a suitable diameter may need to be drilled to

allow bolts to be attached to the bars at the same locations as mentioned above.

d) Secure each clamp by attaching plain washer, spring washer, and nut, in that order.

e) Both of close-ups of Figure h, indicating the middle clamps and Figure i, indicating the side

clamps for reference. Suggest the dimensions for middle clamps are:

a

≥

40 mm,

b

≥

26 mm,

c

= 8 mm,

d

≥ 28 mm, and

Ø

= 9 mm. The torque for tightening the nut and bolts

are recommended 17~23Nm when the property class of bolts and screws is Class 8.8.