9

4.2 Grounding

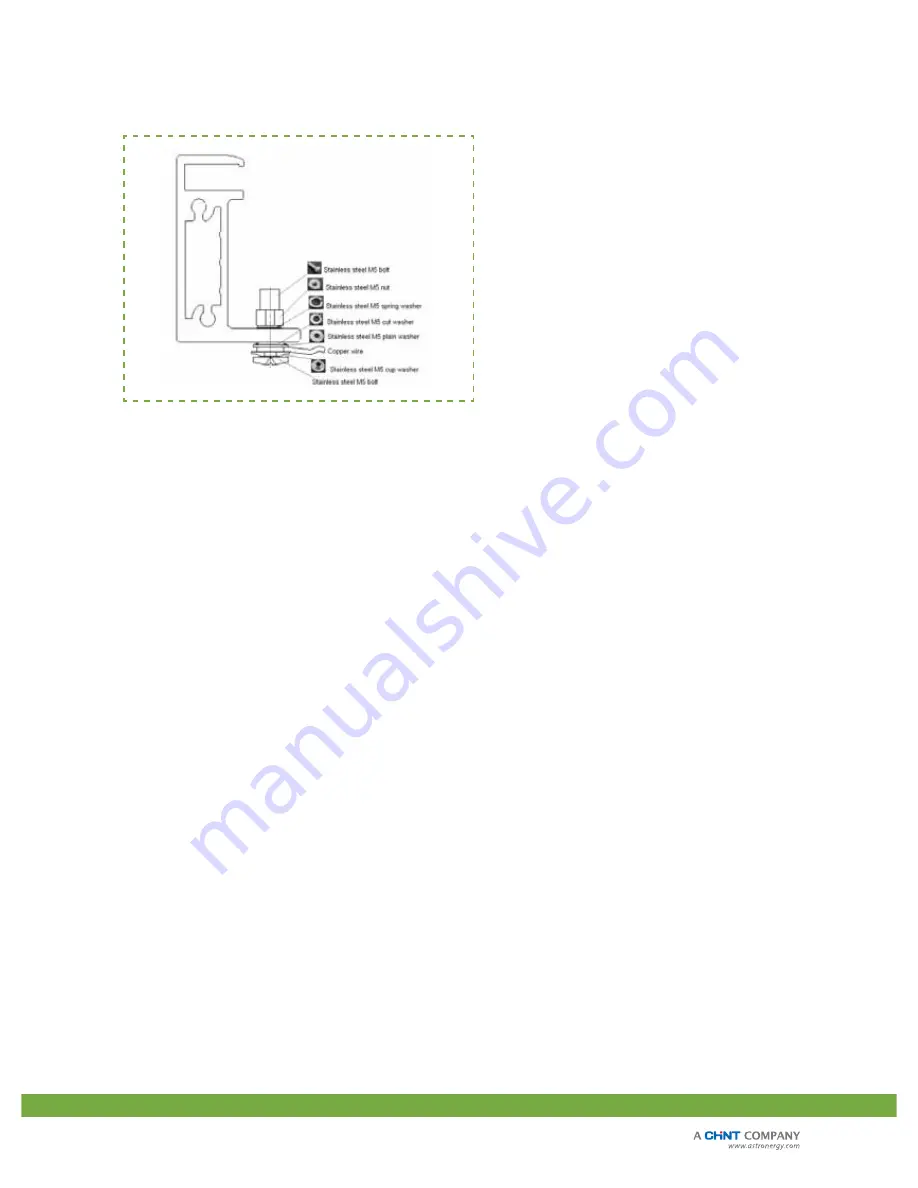

Figure 7. Grounding the aluminum frame with copper wire.

4.2.1

Use the marked 5.5 mm grounding holes (5.5mm) to ground the anodized frame. Use an M5 nut, two M5 cut washers,

an M5 plain washer, an M5 spring washer, and an M5 bolt and a copper wire. All nuts, bolts, and washers are type M5

and should be made of stainless steel (as in figure 8).

4.2.2

Put the bolt through the cup washer and wrap the copper wire around the bolt. (Note that the copper wire cannot be

attached directly to the aluminum.)

4.2.3

Put the bolt through the cut washer and then through the hole in the aluminum frame.

4.2.4

Add the spring washer and nut on the other side of the bolt and tighten to secure all parts. The tightening torque

should be 210±20 N•cm.

5. Maintenance

5.1

Regularly carry out a visual inspection for dirt, dust, bird dropping, leaves, and other detritus covering the modules.

5.2

If there is a build-up of dirt or dust on the module surface, wash the module with clean water and a gentle implement

(a sponge). Never use chemicals on the surface of the module.

5.3

If snow is present, a soft-bristled brush with soft bristles may be used to clean the surface of the modules.

5.4

Regular electrical and mechanical inspection by a licensed professional will keep the system safe and operating at

maximum efficiency.